While both are essential tools for high-temperature processing, the primary benefit of a tube furnace over a chamber furnace is its superior capability for atmosphere control. The enclosed, cylindrical geometry of a tube furnace makes it significantly easier and more effective to maintain a pure, controlled environment around the sample, preventing oxidation and contamination during heating.

The choice between a tube and chamber furnace is not about which is "better," but which geometry best serves your process. A tube furnace excels at precise environmental control for linear or small-volume samples, while a chamber furnace provides capacity for larger, bulkier items.

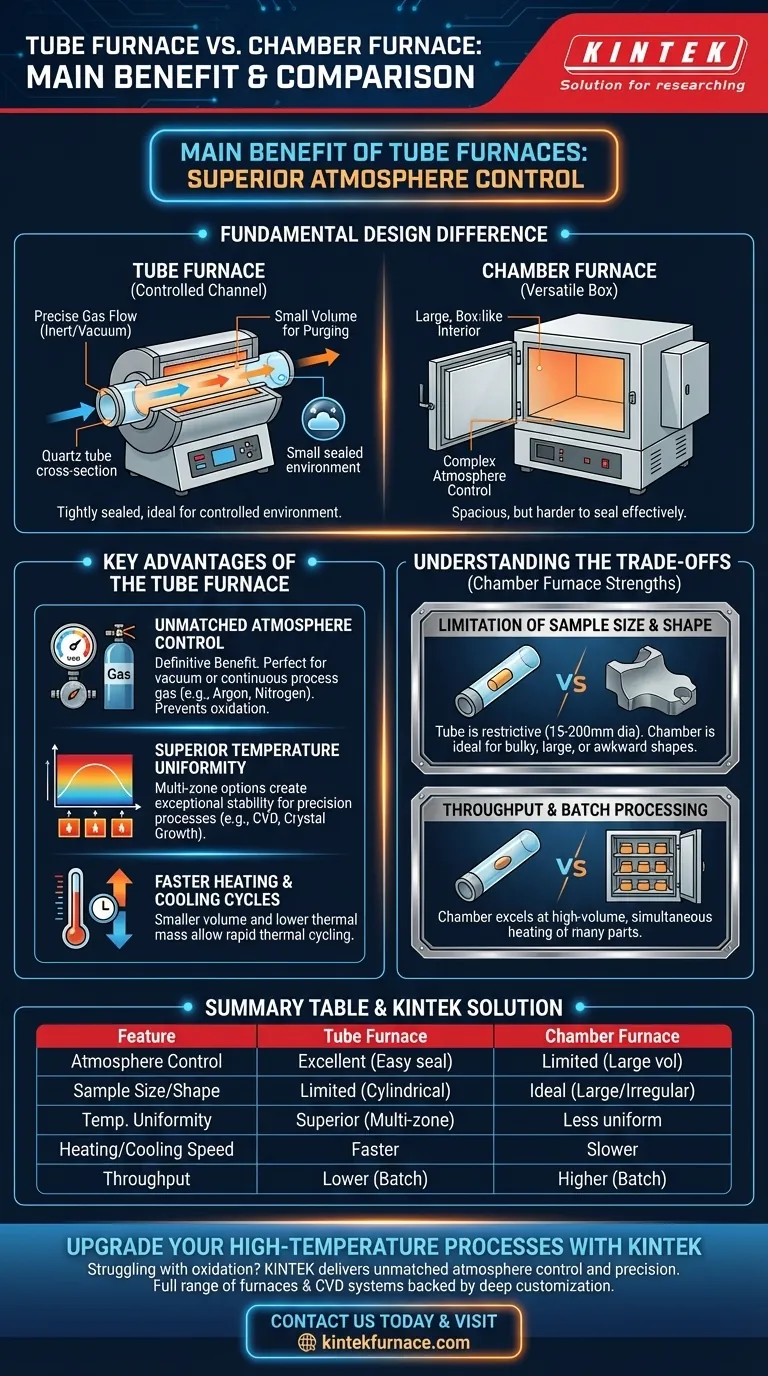

The Fundamental Design Difference

The core distinction between these two furnaces lies in the shape and accessibility of their heating zones. This fundamental difference dictates their ideal applications.

The Tube Furnace: A Controlled Channel

A tube furnace uses a cylindrical tube, typically made of ceramic or quartz, as its heating chamber. Materials are placed inside or passed through this tube.

This narrow, enclosed design is perfectly suited for creating a tightly sealed environment. It requires a relatively small volume of gas to purge the air and introduce a specific atmosphere, such as an inert gas (argon, nitrogen) or even a vacuum.

The Chamber Furnace: A Versatile Box

A chamber furnace, often called a box or muffle furnace, features a large, rectangular interior. It functions like a high-temperature oven, with a front-facing door for loading and unloading samples.

Its spacious design is ideal for heating multiple samples at once, large or irregularly shaped objects, or items that need to be placed on flat shelves. However, controlling the atmosphere in this large volume is more complex and less efficient than in a tube furnace.

Key Advantages of the Tube Furnace

The unique geometry of the tube furnace provides several distinct advantages for specific scientific and industrial processes.

Unmatched Atmosphere Control

This is the definitive benefit. For applications where exposure to oxygen or other ambient gases would ruin the sample—such as in semiconductor manufacturing, advanced materials synthesis, or annealing sensitive alloys—the tube furnace is the standard.

Its design makes it simple to achieve and maintain a high-purity vacuum or a continuous flow of a specific process gas.

Superior Temperature Uniformity

Many tube furnaces are available in multi-zone configurations (e.g., three zones). By controlling the temperature in each zone independently, these furnaces can create an exceptionally uniform and stable temperature profile along the entire length of the sample.

This level of precision is critical for processes like crystal growth or chemical vapor deposition (CVD), where even minor temperature variations can compromise the result.

Faster Heating and Cooling Cycles

Due to their smaller volume and lower thermal mass compared to a bulky chamber furnace, tube furnaces can often heat up and cool down much more quickly. This increases throughput for processes involving smaller samples and rapid thermal cycling.

Understanding the Trade-offs

Choosing a tube furnace also means accepting its inherent limitations, which is why chamber furnaces remain indispensable for many applications.

The Limitation of Sample Size and Shape

The most obvious trade-off is sample geometry. A tube furnace is restrictive, limited to samples that can fit within a tube diameter that typically ranges from 15 mm to 200 mm.

Large, bulky, or awkwardly shaped components simply will not fit. For these, the open, box-like design of a chamber furnace is the only viable option.

Throughput and Batch Processing

While a tube furnace is efficient for its size, a chamber furnace excels at high-volume batch processing. Its larger interior allows you to heat many samples simultaneously, making it far more practical for applications like heat-treating batches of metal parts or ashing large quantities of material.

Making the Right Choice for Your Process

Your final decision must be guided by the specific requirements of your material and your desired outcome.

- If your primary focus is material purity and preventing oxidation: A tube furnace is the definitive choice for its unmatched atmosphere control.

- If your primary focus is processing large or irregularly shaped samples: A chamber furnace is the only practical solution.

- If your primary focus is high-precision temperature uniformity along an axis: A multi-zone tube furnace offers superior performance.

- If your primary focus is high-volume batch processing: A chamber furnace provides the necessary capacity and throughput.

Ultimately, understanding the strengths and weaknesses of each furnace design empowers you to select the right tool for the job.

Summary Table:

| Feature | Tube Furnace | Chamber Furnace |

|---|---|---|

| Atmosphere Control | Excellent (easy to seal, small gas volume) | Limited (large volume, less efficient) |

| Sample Size/Shape | Limited to cylindrical or small samples | Ideal for large, bulky, or irregular samples |

| Temperature Uniformity | Superior with multi-zone options | Less uniform, varies with design |

| Heating/Cooling Speed | Faster due to lower thermal mass | Slower due to higher thermal mass |

| Throughput | Lower for batch processing | Higher for batch processing |

Upgrade Your High-Temperature Processes with KINTEK

Struggling with oxidation or contamination in your experiments? KINTEK's advanced tube furnaces deliver unmatched atmosphere control and precision for applications like semiconductor manufacturing and materials synthesis. Leveraging exceptional R&D and in-house manufacturing, we offer a full range of solutions including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization to meet your unique needs.

Contact us today to discuss how our high-temperature furnace solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab