In short, calibration is the most critical maintenance procedure for a dental furnace. It ensures the temperature displayed on the screen is the actual temperature inside the firing chamber, which is the only way to guarantee the strength, aesthetics, and clinical success of your ceramic restorations. Without it, you are working with an unknown variable that directly compromises your final product.

The core issue is that furnace temperature accuracy naturally drifts over time. Calibration is not just routine maintenance; it is the fundamental quality control process that ensures your dental materials are fired precisely as their manufacturers intended, preventing costly remakes and clinical failures.

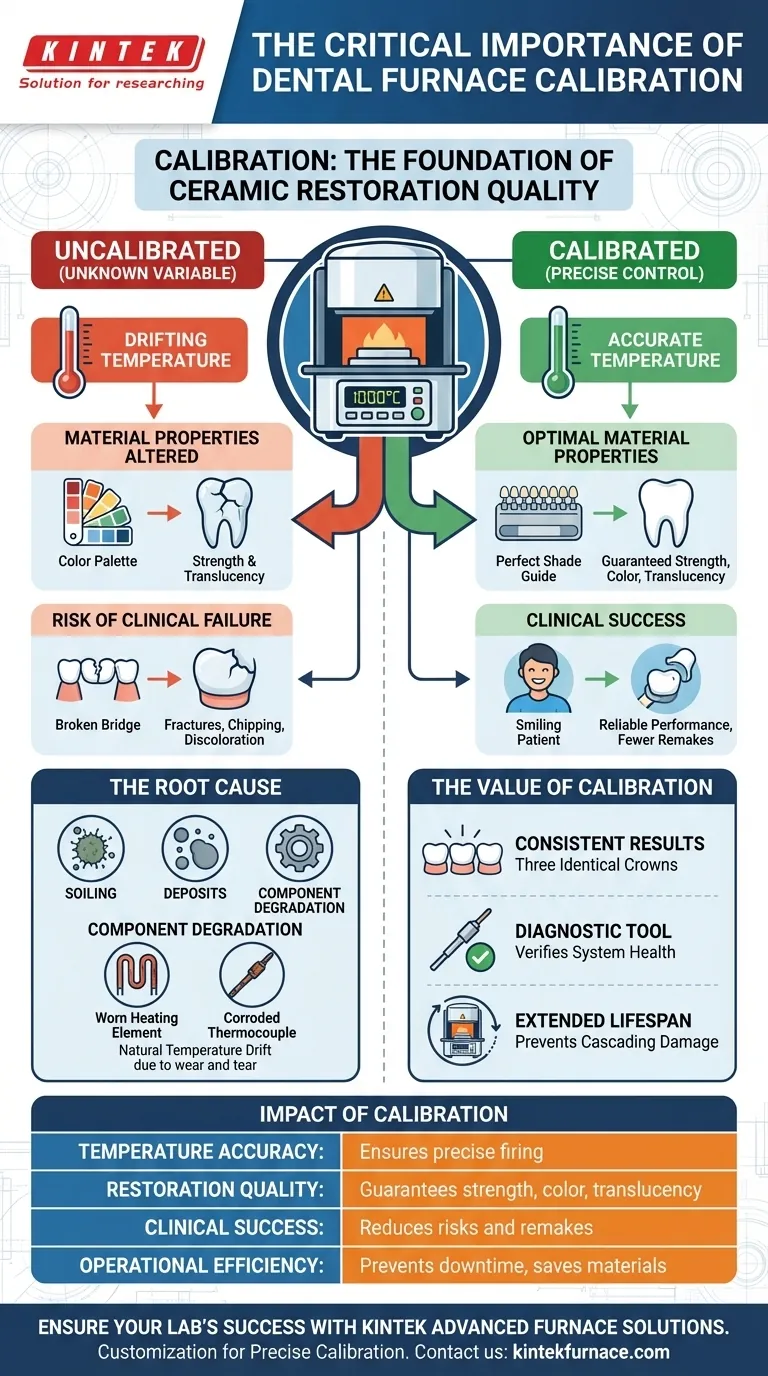

How Temperature Inaccuracy Silently Undermines Your Restorations

An uncalibrated furnace introduces an unacceptable level of uncertainty into your workflow. Even a minor temperature deviation can have a significant and negative impact on the final restoration, often in ways that are not immediately obvious.

The Impact on Material Properties

The physical and aesthetic properties of modern dental ceramics are achieved within very specific temperature ranges.

When the temperature is inaccurate, you risk altering key characteristics such as the final color, translucency, and strength. It can also affect the material's coefficient of thermal expansion and its long-term solubility, directly impacting its clinical performance.

The Risk of Clinical Failure

These subtle shifts in material properties can lead to serious clinical failures down the line. A restoration fired at the wrong temperature may look acceptable initially but could be prone to fractures, chipping, or discoloration once in service.

This not only damages your lab's reputation but also necessitates costly remakes and additional chair time for the clinician.

The Root Cause of Temperature Drift

A furnace's temperature accuracy is not static. It naturally drifts over time due to a combination of factors.

Soiling, deposits, and chemical or physical changes to the heating elements and thermocouple slowly degrade their performance. Calibration is the only way to measure and correct this inevitable drift.

Understanding the Trade-offs and Risks of Neglect

Skipping calibration may seem like a way to save time or money in the short term, but it is a false economy that creates significant downstream costs and risks.

The True Cost of Inconsistent Results

An uncalibrated furnace produces inconsistent results. A crown fired on Monday may have a different shade or strength than an identical one fired on Friday, leading to a frustrating lack of predictability.

This inconsistency is a direct cause of remakes, wasted materials, and lost productivity. The cost of one failed case often exceeds the cost of a full year's calibration schedule.

Masking Deeper Component Failure

Regular calibration is also a diagnostic tool. It verifies that the thermocouple, heating element, and insulation are all functioning correctly as a system.

Neglecting this process can mask the early signs of component wear. A furnace may appear to be working while its heating elements are slowly degrading, leading to an unexpected and catastrophic failure during a critical firing cycle.

Reducing Furnace Lifespan

Routine maintenance, of which calibration is a key part, helps identify and mitigate issues like dirty or corroded components. Addressing this wear and tear proactively prevents cascading damage and significantly extends the operational lifespan of the furnace, protecting your investment.

How to Apply This to Your Lab

Your approach to calibration should be directly tied to your operational priorities. It is not an optional task but a foundational pillar of quality control.

- If your primary focus is consistent aesthetic outcomes: Calibration is non-negotiable for achieving the precise shade and translucency your clients demand.

- If your primary focus is structural integrity and durability: Accurate firing temperatures are essential to ensure every restoration meets its specified strength and avoids premature clinical failure.

- If your primary focus is operational efficiency and profitability: Regular calibration is your best defense against costly remakes, wasted material, and unexpected furnace downtime.

Ultimately, proper furnace calibration gives you control over the quality and consistency of your work.

Summary Table:

| Aspect | Impact of Calibration |

|---|---|

| Temperature Accuracy | Ensures actual chamber temperature matches display for precise firing |

| Restoration Quality | Guarantees strength, color, and translucency of ceramic materials |

| Clinical Success | Reduces risks of fractures, chipping, and costly remakes |

| Operational Efficiency | Prevents downtime, wasted materials, and extends furnace lifespan |

Ensure your dental lab's success with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, and Vacuum & Atmosphere Furnaces, tailored to your unique needs. Our deep customization capabilities guarantee precise calibration and reliable performance for consistent, high-quality restorations. Don't let temperature inaccuracy compromise your work—contact us today to discuss how we can enhance your lab's efficiency and outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations