Using a dental lab furnace involves a precise sequence of steps to transform raw materials into finished dental restorations. The general procedure begins with ensuring the furnace is clean, setting the correct temperature profile for the specific material, and running the automated heating cycle. After the process—whether melting, firing, or sintering—is complete, the restoration must be allowed to cool properly before it can be safely removed for finishing.

The core challenge is not simply following a procedure, but understanding that different furnaces serve distinct purposes. The key to producing high-quality dental work lies in matching the correct furnace type—such as a porcelain or sintering furnace—and its specific operating protocol to the material being processed.

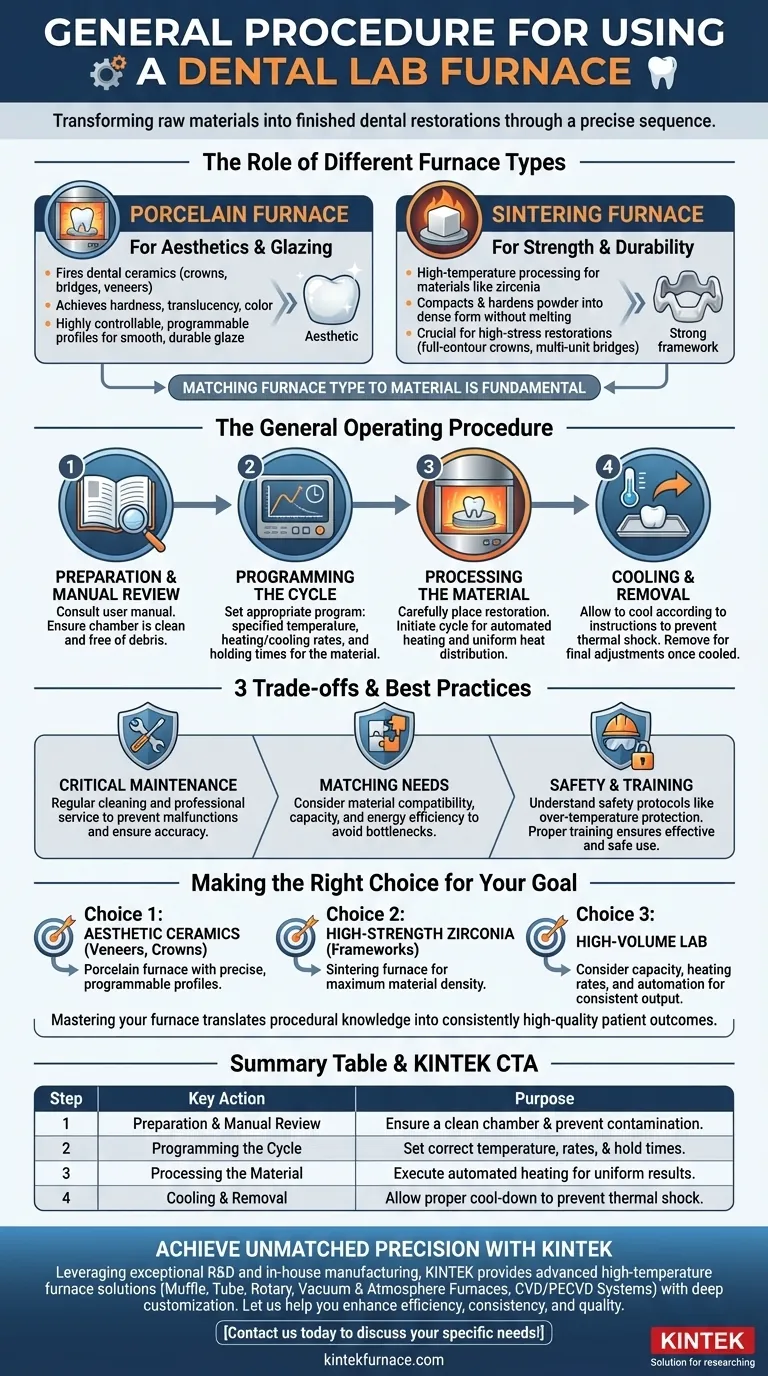

The Role of Different Furnace Types

A "dental lab furnace" is not a single tool but a category of equipment, each designed for a specific task. Understanding the distinction between the primary types is fundamental to achieving the desired clinical outcomes.

The Porcelain Furnace: For Aesthetics and Glazing

A porcelain furnace is used for firing dental ceramics like crowns, bridges, and veneers. Its primary function is to heat these restorations to achieve the desired hardness, translucency, and color.

These furnaces feature highly controllable, programmable settings. This allows technicians to create specific temperature profiles required for different ceramic materials, ensuring an aesthetic, smooth, and durable glazed finish.

The Sintering Furnace: For Strength and Durability

A sintering furnace is engineered for the high-temperature processing of materials like zirconia. Sintering is a process that compacts and hardens powdered materials into a solid, dense form without melting them.

This method is crucial for creating zirconia restorations with optimal strength and structural integrity. It is the go-to equipment for labs producing high-stress restorations like full-contour crowns and multi-unit bridges.

The General Operating Procedure

While the exact parameters will vary based on the furnace model and dental material, the core operational workflow follows a consistent pattern.

Step 1: Preparation and Manual Review

Before any operation, always consult the user manual for your specific model. Ensure the furnace chamber is clean and completely free of any debris from previous cycles, as contamination can compromise the final product.

Step 2: Programming the Cycle

Turn on the furnace and set the appropriate program. This involves inputting the specified temperature, heating and cooling rates, and holding times required for the dental material you are using, whether it's porcelain powder or a milled zirconia framework.

Step 3: Processing the Material

Carefully place the dental restoration into the furnace. Once the cycle is initiated, the furnace will automatically execute the programmed heating and processing sequence, ensuring uniform heat distribution for consistent results.

Step 4: Cooling and Removal

After the cycle concludes, the restoration must be allowed to cool down according to the manufacturer's instructions. Removing it too quickly can induce thermal shock, leading to cracks and structural failure. Once cooled, it can be safely removed for final adjustments.

Understanding the Trade-offs and Best Practices

Effective furnace operation goes beyond the daily steps; it involves strategic maintenance and selection to ensure long-term reliability and quality.

The Critical Role of Maintenance

Regular maintenance is non-negotiable for optimal performance and longevity. Clean the furnace and its components regularly and schedule a professional service check at least once a year to prevent malfunctions and ensure continued accuracy.

Matching the Furnace to Your Lab's Needs

Selecting the right furnace is a critical decision. Key factors include material compatibility, furnace capacity relative to your production volume, and energy efficiency. Choosing a furnace that doesn't align with your lab's primary materials or workload can create significant bottlenecks.

The Importance of Safety and Training

Modern furnaces are designed with safety features like over-temperature protection and emergency shut-offs. Proper training ensures that operators not only use the equipment effectively but also understand and can implement these crucial safety protocols.

Making the Right Choice for Your Goal

Your choice and use of a furnace must align directly with the types of restorations you produce to guarantee quality and efficiency.

- If your primary focus is aesthetic ceramic restorations (veneers, crowns): A porcelain furnace with precise, programmable temperature profiles is essential for achieving the correct translucency and glaze.

- If your primary focus is high-strength zirconia frameworks and full-contour crowns: A sintering furnace is non-negotiable for ensuring maximum material density and durability.

- If you are managing a high-volume lab: Carefully consider furnace capacity, heating rates, and automated features to prevent production delays and ensure consistent output.

Ultimately, mastering your dental furnace is about translating procedural knowledge into consistently high-quality patient outcomes.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Preparation & Manual Review | Ensure a clean chamber and prevent contamination |

| 2 | Programming the Cycle | Set correct temperature, heating/cooling rates, and hold times |

| 3 | Processing the Material | Execute automated heating for uniform results |

| 4 | Cooling & Removal | Allow proper cool-down to prevent thermal shock |

Achieve Unmatched Precision in Your Dental Lab

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you specialize in aesthetic porcelain restorations or high-strength zirconia frameworks, KINTEK's expertise ensures your furnace is perfectly matched to your materials and production volume. Let us help you enhance efficiency, consistency, and the quality of your patient outcomes.

Contact us today to discuss your specific needs and discover the right furnace solution for your lab!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations