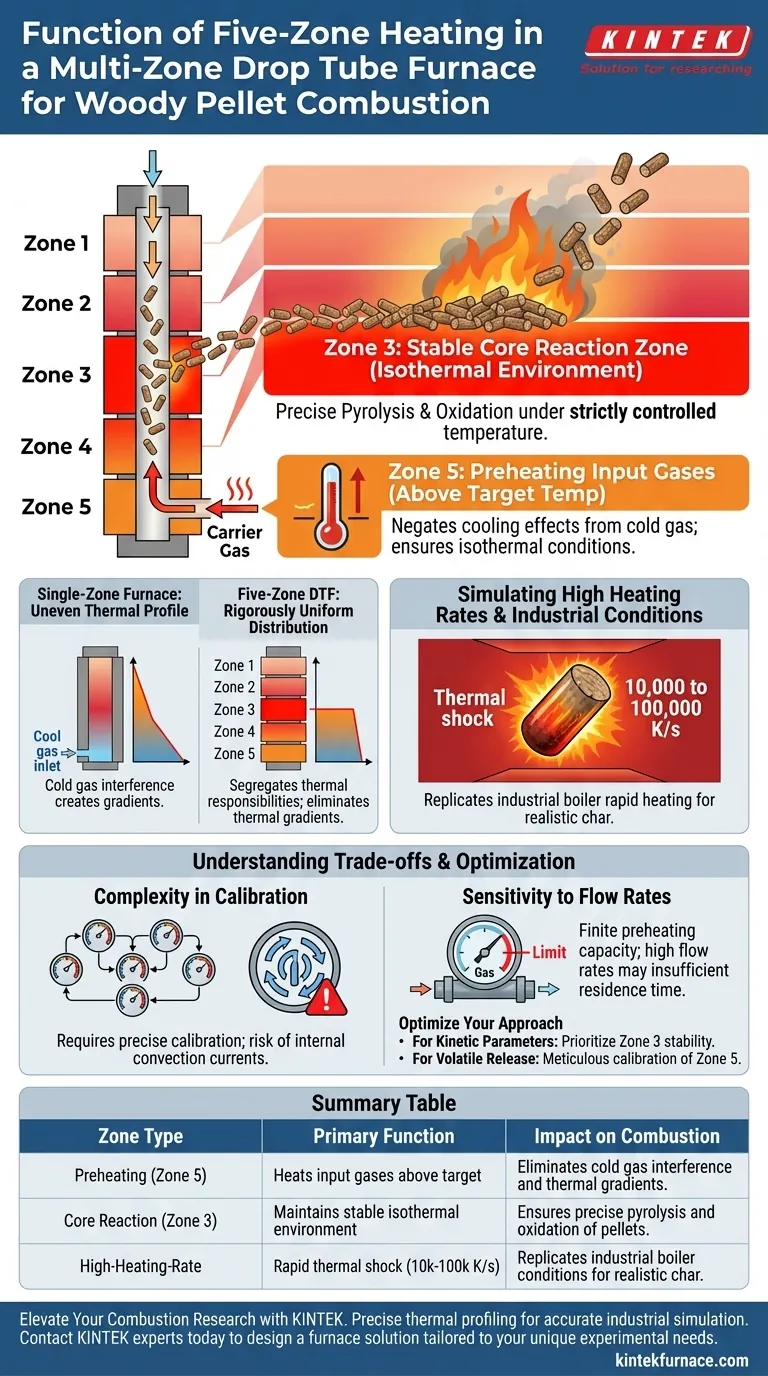

The five-zone heating layout functions primarily to establish a rigorously uniform temperature distribution across the reactor by segregating thermal responsibilities. It utilizes specific zones, such as Zone 5, to preheat input gases above the experimental target to negate cooling effects, while creating a stable, isothermal environment in central zones (like Zone 3) for the precise pyrolysis and oxidation of woody pellets.

The multi-zone configuration is designed to decouple gas heating from the reaction environment. By pre-conditioning gases before they reach the sample, the system eliminates thermal gradients, ensuring the fuel particles undergo combustion under the strictly controlled, high-heating-rate conditions required to mimic industrial boilers.

Achieving Thermal Precision in Combustion

The Drop Tube Furnace (DTF) is not merely a heater; it is a simulator for the extreme conditions found in industrial power plants. The five-zone layout is the mechanism that allows this simulation to be accurate and repeatable.

Eliminating Cold Gas Interference

In single-zone furnaces, introducing carrier gases can lower the temperature at the inlet, creating an uneven thermal profile. The five-zone layout addresses this by designating specific areas, such as Zone 5, for preheating.

By heating input gases to a temperature slightly higher than the target experimental temperature, the system compensates for potential heat loss. This ensures that when the gas stream reaches the reaction area, it does not act as a coolant.

Creating a Stable Core Reaction Zone

The central section of the furnace, typically Zone 3, functions as the primary reaction chamber. Because the gases entering this zone are already thermally equilibrated, Zone 3 maintains a highly stable thermal environment.

This stability is critical for observing the behavior of woody pellets. It ensures that the pyrolysis and oxidation processes occur under controlled isothermal conditions, unaffected by external fluctuations or thermal shock from cold air.

Simulating High Heating Rates

The ultimate goal of this thermal stability is to replicate the rapid heating rates of industrial boilers. Within the stable environment of the core zone, particles experience heating rates as high as 10,000 to 100,000 K/s.

This intense thermal shock drives rapid devolatilization and char oxidation. The five-zone layout ensures that these rates are achieved consistently, allowing researchers to produce char that closely resembles that of actual industrial combustion.

Understanding the Trade-offs

While a five-zone layout offers superior precision, it introduces complexity into the experimental setup.

Complexity in Calibration

Achieving a perfectly flat temperature profile requires the precise calibration of five independent heating elements. If the interaction between zones is not carefully managed, you may inadvertently create internal convection currents that disturb the laminar flow required for accurate particle trajectory.

Sensitivity to Flow Rates

The preheating capacity of zones like Zone 5 is finite. If the experiment requires exceptionally high gas flow rates, the residence time in the preheating zone may be insufficient, potentially reintroducing thermal gradients into the core reaction zone.

Optimizing Your Experimental Approach

To leverage the full potential of a five-zone Drop Tube Furnace, align your configuration with your specific research objectives.

- If your primary focus is determining kinetic parameters: Prioritize the stability of Zone 3, ensuring the temperature deviation is negligible to validate thermogravimetric indices.

- If your primary focus is studying volatile release: meticulous calibration of Zone 5 is essential to ensure gases are fully preheated, guaranteeing that ignition occurs exactly when the particle enters the reaction zone.

The five-zone layout is the difference between simply burning a sample and accurately simulating the physics of industrial power generation.

Summary Table:

| Zone Type | Primary Function | Impact on Combustion |

|---|---|---|

| Preheating (Zone 5) | Heats input gases above target | Eliminates cold gas interference and thermal gradients. |

| Core Reaction (Zone 3) | Maintains stable isothermal environment | Ensures precise pyrolysis and oxidation of pellets. |

| High-Heating-Rate | Rapid thermal shock (10k-100k K/s) | Replicates industrial boiler conditions for realistic char. |

Elevate Your Combustion Research with KINTEK

Precise thermal profiling is the cornerstone of accurate industrial simulation. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, including sophisticated multi-zone Drop Tube Furnaces. Our systems are fully customizable to meet the rigorous demands of your woody pellet and fuel research.

Ready to eliminate thermal gradients in your lab? Contact KINTEK experts today to design a furnace solution tailored to your unique experimental needs.

Visual Guide

References

- Guillaume Gerandi, Valérie Tschamber. Particulate and gaseous emissions during combustion of wood pellets under low and high heating rates in a drop tube furnace. DOI: 10.2139/ssrn.5600417

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What role does a quartz tube furnace play in polyimide pyrolysis? Precision Control for Carbon Molecular Sieves

- Why is a high-temperature tubular furnace required for the activation process of walnut shell activated carbon at 700°C?

- What environmental parameters must high-temperature furnaces maintain for YIG thin film annealing? Expert Guide

- What physical conditions does a tube furnace provide for biomass pyrolysis? Master Thermal Control for Bio-Energy

- How does a tube vacuum furnace ensure quality during the solution treatment of aluminum matrix composites? Unlock Precision and Purity for Superior Materials

- Why is vacuum sealing of a reaction tube necessary during the in-situ solvothermal growth of BiVO4/COF?

- How are vertical fluidized bed tube furnaces utilized in material handling and processing? Achieve Uniform Thermal Processing for Powders

- How does a benchtop tube furnace ensure the quality of silicon nitride green bodies? Master Debinding Precision