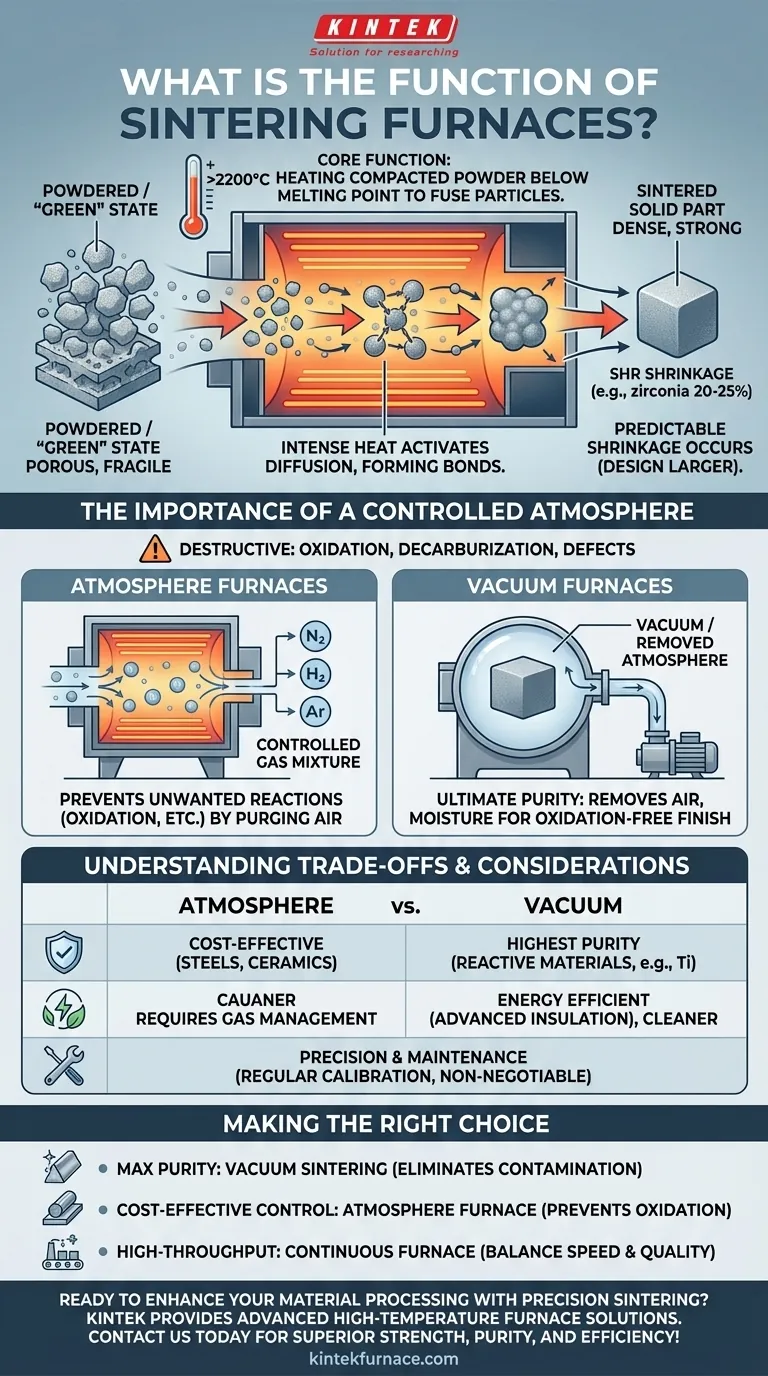

At its core, a sintering furnace functions by heating a compacted powder or milled material to an extreme temperature just below its melting point. This thermal energy causes the individual particles to bond and fuse together, transforming a fragile, porous object into a dense, solid, and significantly stronger final part without ever becoming a liquid.

The essential role of a sintering furnace is not simply to generate heat, but to precisely manage a high-temperature environment. This controlled atmosphere—whether a specific gas mixture or a vacuum—is what prevents defects and ensures the material achieves its required strength and density.

How Sintering Transforms Materials

Sintering is a foundational process in fields like powder metallurgy, ceramics, and advanced material science. The furnace provides the critical environment where this physical transformation occurs.

From Powder to Solid

The process starts with a material in a powdered or "green" state, which has been compacted or milled into a desired shape. Inside the furnace, intense heat activates a diffusion process, causing atoms to move between the particles and form strong metallic or ceramic bonds at their points of contact.

A primary application is in dentistry, where zirconia is milled into crowns or bridges. In their initial state, these restorations are chalky and weak. The sintering furnace hardens them into a durable, high-strength ceramic.

The Critical Role of Temperature

Sintering occurs at a precise temperature range, typically 70-90% of the material's absolute melting point. This is hot enough to promote particle bonding but cool enough to prevent the part from melting, deforming, and losing its shape.

To reach these extreme temperatures, which can exceed 2200°C, furnaces often rely on specialized heating elements made from materials like molybdenum disilicide, tungsten, or graphite.

The Inevitable Shrinkage

As the pores between particles are eliminated and the material becomes denser, the part undergoes significant and predictable shrinkage. For materials like zirconia, this shrinkage can be as high as 20-25%.

This is not a defect but an integral part of the process. The initial "green" part must be designed larger than the final dimensions to compensate for this change.

The Importance of a Controlled Atmosphere

Simply heating a material in open air would be destructive. At high temperatures, most materials react aggressively with oxygen and other gases, leading to defects and poor performance. The furnace's most crucial function, besides heating, is managing its internal atmosphere.

Preventing Unwanted Reactions

The primary goal of atmospheric control is to prevent unwanted chemical reactions like oxidation (rusting or scaling) and decarburization (loss of carbon content and strength in steels). A controlled environment ensures the material's chemical integrity is preserved.

Atmosphere Furnaces

These furnaces allow for precise management of the gaseous environment. The chamber is purged of air and filled with a specific, controlled mixture of gases (such as nitrogen, hydrogen, or argon) that protects the material during the heating cycle.

Vacuum Furnaces

A vacuum furnace takes a different approach by removing the atmosphere altogether. Air, moisture, and other gases are pumped out of a sealed chamber to create a vacuum. This is the ultimate way to prevent contamination and achieve a clean, bright, oxidation-free finish on the final part.

Understanding the Trade-offs and Considerations

The choice between different sintering technologies involves balancing purity, cost, and material requirements. Each approach comes with distinct advantages and operational demands.

Atmosphere vs. Vacuum Sintering

Vacuum sintering offers the highest level of purity and is ideal for reactive materials like titanium or superalloys that cannot tolerate any atmospheric contact. However, atmosphere furnaces can be more cost-effective and are perfectly suitable for materials that benefit from or are inert to specific gas environments.

Energy Efficiency and Environmental Impact

Modern vacuum furnaces often feature advanced insulation and heating technology, which helps minimize heat loss and reduce energy consumption. Their sealed design also prevents the release of exhaust gases, making them an environmentally cleaner option compared to some atmosphere furnace designs.

The Need for Precision and Maintenance

Sintering furnaces are sophisticated instruments, not simple ovens. Achieving consistent and repeatable results depends on accurate temperature control and a stable atmosphere. Regular calibration and maintenance are non-negotiable to ensure the furnace performs reliably and has a long service life.

Making the Right Choice for Your Goal

Selecting the correct furnace technology is critical to achieving the desired material properties for your specific application.

- If your primary focus is maximum purity and defect prevention for reactive metals: A vacuum sintering furnace is the superior choice, as it eliminates nearly all sources of atmospheric contamination.

- If your primary focus is processing steels or ceramics that require a specific protective gas: An atmosphere furnace provides the necessary control to prevent oxidation while being a potentially more cost-effective solution.

- If your primary focus is high-throughput production of less-sensitive materials: A continuous horizontal or tube furnace with basic atmospheric controls may offer the best balance of speed and quality.

Ultimately, understanding the furnace's function is key to selecting the right tool to reliably transform raw materials into high-performance components.

Summary Table:

| Function | Key Details |

|---|---|

| Heating | Applies extreme heat (up to 2200°C) below melting point to fuse particles |

| Atmosphere Control | Uses gas mixtures or vacuum to prevent oxidation and defects |

| Material Transformation | Converts powders into dense, solid parts with predictable shrinkage |

| Applications | Powder metallurgy, ceramics, dentistry (e.g., zirconia crowns) |

Ready to enhance your material processing with precision sintering? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our sintering furnaces can deliver superior strength, purity, and efficiency for your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents