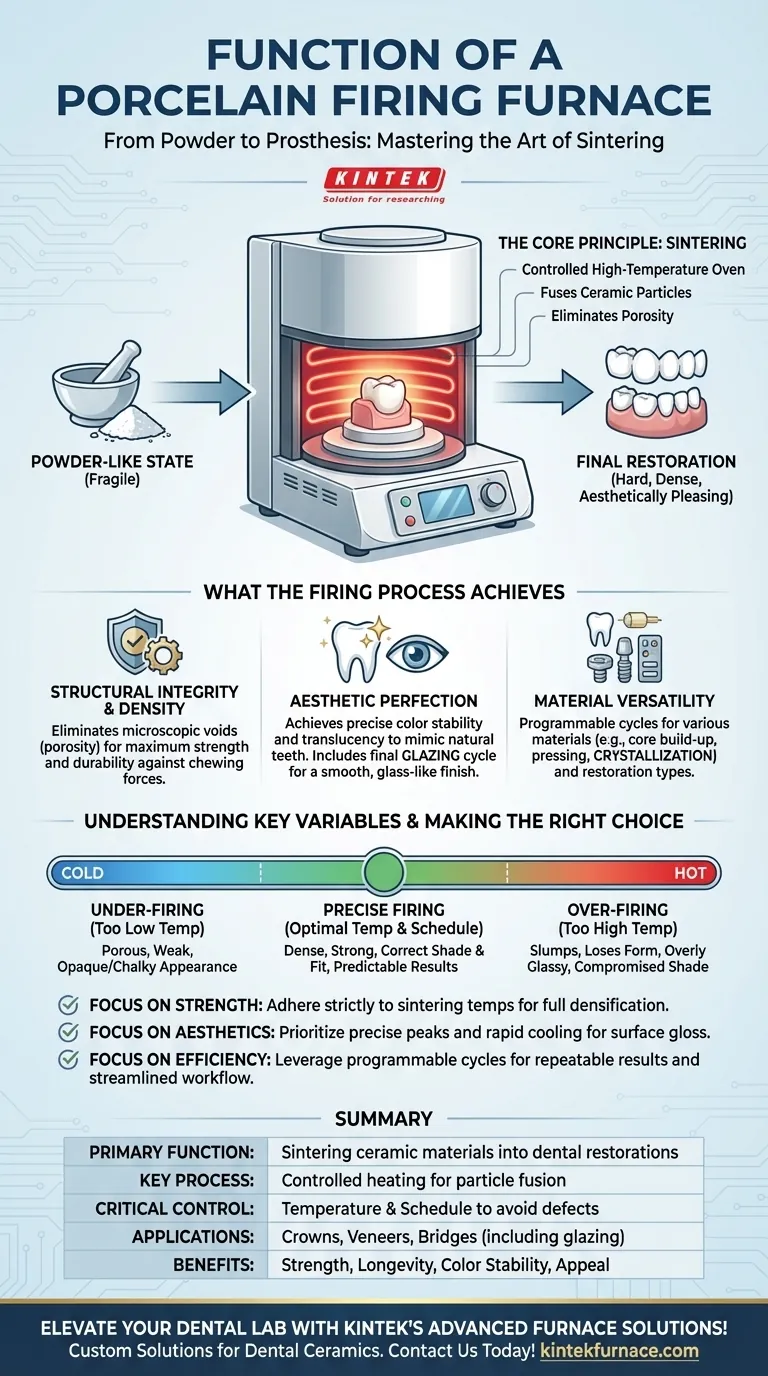

At its core, a porcelain firing furnace is a specialized, high-temperature oven used in dental laboratories. Its primary function is to apply precisely controlled heat to dental ceramic materials, transforming them from a fragile, powder-like state into a hard, dense, and aesthetically pleasing final restoration, such as a crown, veneer, or bridge.

A porcelain furnace is not merely a heating device; it is a precision instrument engineered to control the chemical and physical transformation of ceramic particles. It fuses them into a solid, non-porous structure with predictable strength, color, and longevity.

The Core Principle: From Powder to Prosthesis

The fundamental purpose of the furnace is to execute a process called sintering. This involves heating a compacted ceramic material to a high temperature—but below its melting point—to bond its particles together.

The Firing Chamber

The principal unit of the furnace is its refractory firing chamber. This is where the unfinished dental restorations are placed for processing.

Restorations are carefully positioned on ceramic or metal supports, such as pins, mesh, or firing pads, to ensure they are held securely and that heat circulates around them evenly.

The Sintering Process

Once the chamber is closed, the furnace initiates a controlled firing cycle. The temperature is gradually increased to a specific level and then held for a predetermined period.

This precise thermal cycle allows the ceramic particles to fuse, eliminating gaps and voids. This achieves proper heat distribution and drives the desired chemical and physical changes in the material.

Mechanical Operation

To ensure uniform heating, heating coils are typically arranged concentrically around the restoration within the chamber.

A motor-driven mechanism provides a perfect seal by either raising the firing platform into the chamber or lowering the upper housing over the platform, creating a stable thermal environment.

What the Firing Process Achieves

The controlled environment created by the furnace is essential for producing a clinically acceptable dental restoration. The outcomes directly impact both the function and appearance of the final product.

Structural Integrity and Density

The primary goal of firing is to give the ceramic its strength. The process eliminates porosity, or microscopic voids, which are weak points in the material.

By creating a dense, hardened structure, the furnace ensures the final restoration will have the durability and longevity required to withstand the forces of chewing.

Aesthetic Perfection

Proper firing is critical for achieving the desired color stability and translucency of the porcelain, allowing it to mimic a natural tooth.

Many restorations undergo a final glazing cycle. This involves a quick, high-temperature firing that creates a smooth, glass-like surface, adding a final aesthetic polish and making the restoration more resistant to staining.

Material Versatility

Modern furnaces are highly adaptable. They come with programmable firing cycles and pre-set profiles tailored to the specific needs of different materials and restoration types.

Technicians can select specific programs for tasks like core porcelain build-up, pressing all-ceramic materials, surface glazing, or the crystallization required by certain advanced ceramics.

Understanding the Key Variables

The success of a restoration is entirely dependent on the precision of the firing cycle. Minor deviations can lead to complete failure, making a deep understanding of the variables essential.

The Critical Role of Temperature

Using a temperature that is too low will result in under-firing. The restoration will be porous, weak, and may appear opaque or chalky.

Conversely, a temperature that is too high causes over-firing. This can make the porcelain slump, lose its anatomical form, and appear overly glassy or translucent, often compromising the shade and fit.

The Importance of Firing Schedules

Different ceramic materials have unique chemical compositions that demand specific heating rates, hold times, and cooling periods.

Using the wrong program—for instance, a glazing cycle for a sintering stage—will fail to achieve the required material properties and will ruin the restoration. Strict adherence to the manufacturer's specifications is not optional.

Making the Right Choice for Your Goal

Applying this knowledge requires matching the furnace's capability to the specific outcome you need to achieve for each restoration.

- If your primary focus is strength and density (e.g., a zirconia core): Adhere strictly to the sintering temperature and hold times specified by the material manufacturer to ensure full densification.

- If your primary focus is aesthetics (e.g., final layering or glazing): Prioritize precise temperature peaks and rapid cooling cycles to achieve a surface gloss without altering the underlying structure or color.

- If your primary focus is efficiency (e.g., a high-volume lab): Leverage the furnace's pre-set, programmable cycles to ensure repeatable results, minimize user error, and streamline workflow.

Ultimately, mastering the porcelain furnace is about controlling a transformative process to achieve predictable, high-quality results every time.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Function | Sintering ceramic materials to transform powder into hard, dense dental restorations |

| Key Process | Controlled heating cycles for particle fusion, eliminating porosity |

| Temperature Control | Precise management to avoid under-firing (weakness) or over-firing (deformation) |

| Applications | Crowns, veneers, bridges; includes glazing and crystallization cycles |

| Benefits | Enhanced strength, longevity, color stability, and aesthetic appeal |

Elevate your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, tailored for dental ceramics. Our deep customization ensures your unique experimental needs are met. Contact us today to discuss how our expertise can transform your restoration processes and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity