At its core, a rotary furnace is a slightly inclined, rotating cylinder that continuously tumbles material from an entry point to a discharge point. This design uses gravity and mechanical motion to ensure every particle is mixed and uniformly exposed to a controlled heat source, making it highly effective for continuous processing applications.

The fundamental challenge in large-scale heat treatment is achieving perfect uniformity. A rotary furnace solves this by combining a slight tilt with constant rotation, forcing the material to tumble and mix as it travels, eliminating hot spots and ensuring a consistent final product.

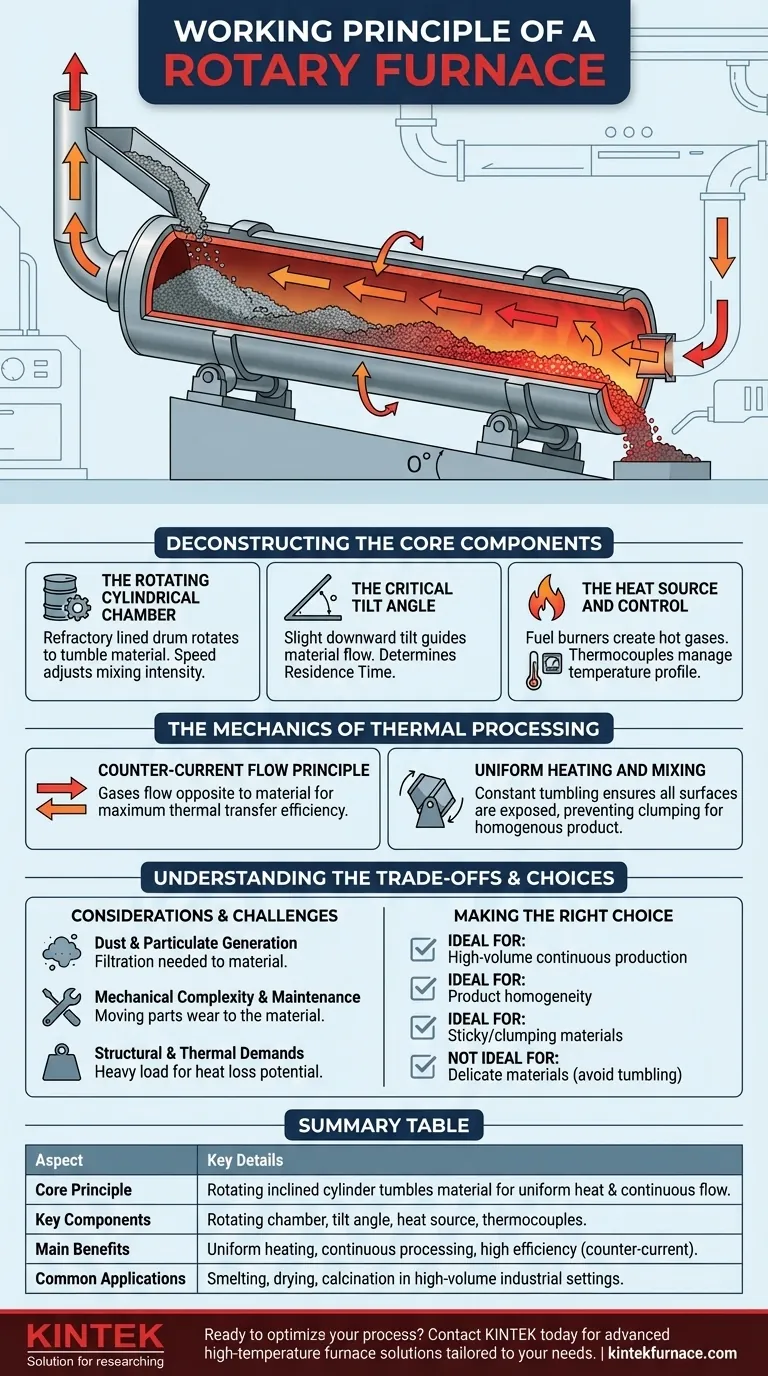

Deconstructing the Core Components

To understand its operation, we must first look at the key mechanical parts and the role each one plays in the process.

The Rotating Cylindrical Chamber

The main body of the furnace is a long, barrel-shaped tube or drum. This chamber is typically made of a metal shell lined with refractory material to withstand extreme temperatures.

This chamber rotates on its axis, driven by an independent motor. The speed of this rotation can be controlled to adjust the intensity of mixing.

The Critical Tilt Angle

The furnace is mounted at a slight downward angle. This tilt is crucial, as it works with the rotation to guide the material through the furnace.

The degree of tilt directly influences the residence time—the amount of time the material spends inside the heated zone. A steeper angle means faster travel and shorter residence time, while a shallower angle increases it.

The Heat Source and Control

Heat is most often supplied by burning pulverized solid, liquid, or gaseous fuel to create hot gases. These gases are directed through the chamber to heat the material.

The temperature is precisely managed using thermocouples, which convert the internal temperature into electrical signals. A controller then adjusts the power to the heating system to maintain the desired temperature profile.

The Mechanics of Thermal Processing

The interaction between the material flow and the heat source is what defines the furnace's efficiency and effectiveness.

Counter-Current Flow Principle

In most applications, the hot gases flow in a counter-current direction, meaning they enter at the material's discharge end and exit at the feed end.

This is a highly efficient design. The hottest, freshest gas comes into contact with the hottest, most-processed material, while the cooler, exiting gas preheats the cold, raw material entering the furnace, maximizing thermal transfer.

Uniform Heating and Mixing

The single most important benefit of the design is the tumbling action created by the rotation. This constant movement ensures that all surfaces of the material are exposed to the heat source.

This action prevents material from sticking to the furnace walls, breaking up clumps, and guaranteeing a homogenous mixture. This is critical for processes like smelting, drying, or calcination where consistency is paramount.

Continuous vs. Batch Processing

The angled, rotating design is inherently built for continuous processing. Material can be constantly fed into the high end and finished product can be constantly removed from the low end.

This makes it ideal for high-volume industrial applications where stopping and starting a furnace for individual batches would be inefficient.

Understanding the Trade-offs

While highly effective, the rotary furnace design comes with specific considerations that may not be suitable for every application.

Dust and Particulate Generation

The tumbling action that is so beneficial for mixing can also create significant amounts of dust, especially with fine or brittle materials. This often requires complex filtration and dust collection systems to manage environmental and safety standards.

Mechanical Complexity and Maintenance

Compared to a static furnace, a rotary furnace has many moving parts. The drive motor, support rollers, and seals at either end of the rotating drum are points of wear that require regular inspection and maintenance.

Structural and Thermal Demands

The large, heavy rotating drum places significant structural demands on its foundation and support system. Furthermore, heat loss can occur through the large surface area of the furnace shell and at the seals where the rotating drum meets the stationary feed and discharge chutes.

Making the Right Choice for Your Process

Deciding if a rotary furnace is the correct tool depends entirely on the material you are processing and your production goals.

- If your primary focus is high-volume, continuous production: The automated, continuous flow of a rotary furnace is superior to the start-stop nature of batch furnaces.

- If your primary focus is product homogeneity: The constant mixing and tumbling action is a key advantage that guarantees a level of uniformity static furnaces cannot match.

- If your primary focus is processing sticky or clumping materials: The self-cleaning motion of the rotating drum is essential for preventing buildup and ensuring consistent material flow.

- If your primary focus is processing delicate materials or minimizing dust: A static or belt furnace might be a more suitable choice to avoid the degradation caused by the tumbling action.

By understanding these core principles, you can effectively determine if the unique capabilities of a rotary furnace align with your specific material processing goals.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Principle | Rotating inclined cylinder tumbles material for uniform heat exposure and continuous flow. |

| Key Components | Rotating chamber, tilt angle, heat source with thermocouples for temperature control. |

| Main Benefits | Uniform heating, continuous processing, high efficiency with counter-current flow. |

| Common Applications | Smelting, drying, calcination in high-volume industrial settings. |

| Considerations | Dust generation, mechanical complexity, maintenance needs, structural demands. |

Ready to optimize your industrial heat treatment process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our rotary furnaces, part of a diverse product line including Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are designed for superior performance and deep customization to meet your unique experimental and production requirements. Contact us today to discuss how our expertise can enhance your efficiency and product quality!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput