In dentistry, sintering is a critical high-temperature process that transforms a soft, chalk-like milled dental restoration into its final, dense, and incredibly strong state. This heat treatment, typically applied to zirconia restorations like crowns and bridges, uses temperatures between 1,400°C and 1,600°C to fuse the material's particles together. This step is what gives modern ceramic restorations their renowned durability and longevity.

Sintering is not merely a heating step; it is the essential transformation that converts a fragile, oversized zirconia shape into a precisely fitted and robust final restoration. It is the bridge between digital design and clinical reality.

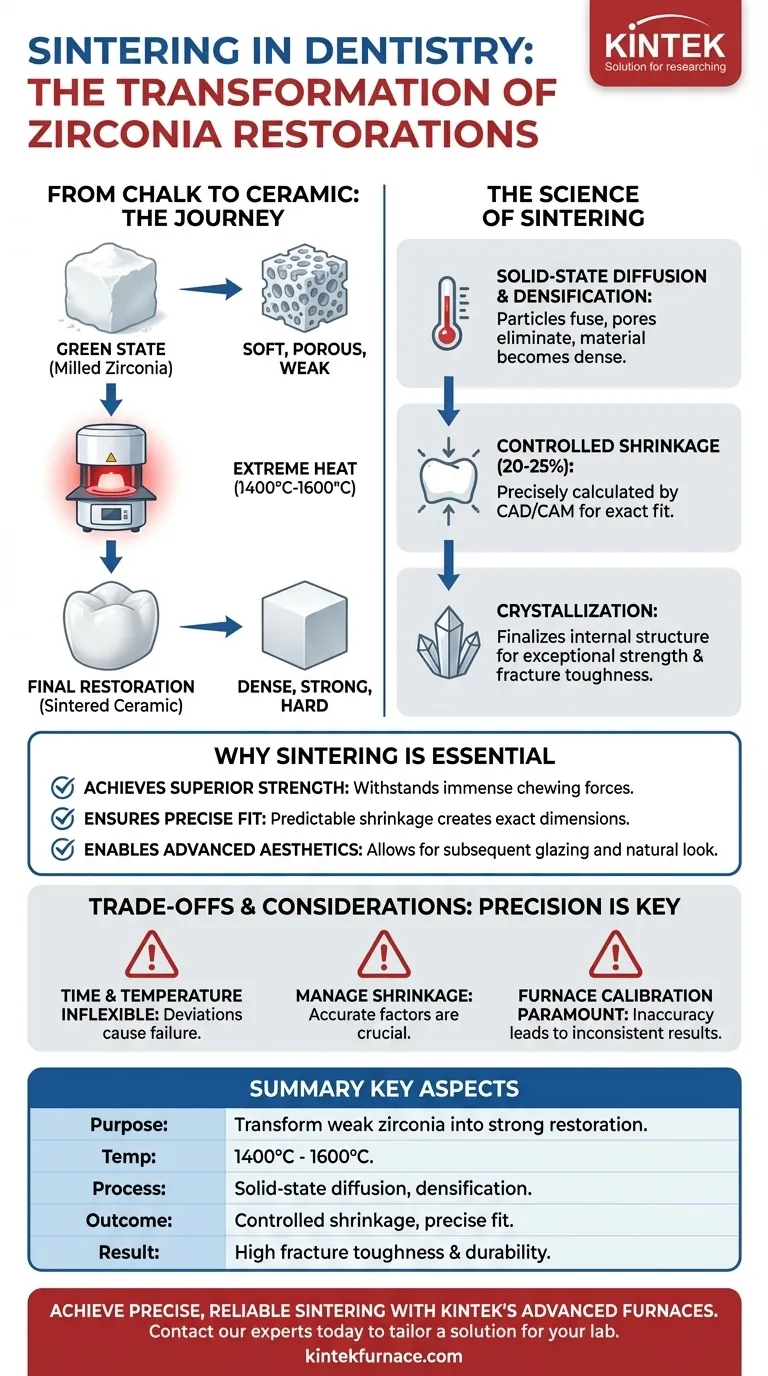

The Science of Sintering: From Chalk to Ceramic

To understand its importance, you must first understand the material's journey. A zirconia crown does not start as a hard block; it is milled from a much softer, more workable material.

The "Green State" Material

Zirconia restorations begin their life in a pre-sintered or "green state." This material has the consistency of chalk and is porous and weak.

This soft state is intentional. It allows complex anatomical shapes like crowns and multi-unit bridges to be milled quickly and with minimal stress on the milling equipment.

The Role of Extreme Heat

Once milled, the green-state restoration is placed in a specialized dental furnace. The furnace slowly heats the zirconia to a peak temperature, often around 1,500°C, and holds it there for a specific period.

This extreme heat does not melt the material. Instead, it provides the energy for a process called solid-state diffusion, where the individual zirconia particles fuse together at their points of contact.

Densification and Shrinkage

As the particles fuse, the microscopic pores between them are eliminated. This process, known as densification, is what makes the final material incredibly hard and non-porous.

A direct and crucial consequence of densification is shrinkage. The restoration shrinks uniformly by as much as 20-25% in volume. This shrinkage is precisely calculated by the CAD/CAM software, which initially designs the restoration in an oversized form to compensate.

Finalizing the Crystal Structure

The heat cycle also finalizes the material's internal crystal structure. This crystallization optimizes the arrangement of the zirconia molecules, providing the exceptional fracture toughness and strength that the material is known for.

Why Sintering is Essential for Modern Restorations

Sintering is not an optional finishing step; it is a core manufacturing process that defines the restoration's success. Without it, high-strength ceramics like zirconia would be unusable in dentistry.

Achieving Superior Strength

The primary purpose of sintering is to achieve the material's specified strength. The process transforms the weak, chalky pre-form into a monolithic ceramic capable of withstanding the immense chewing forces in the mouth.

Ensuring a Precise Fit

While shrinkage may sound like a problem, it is a controlled and essential part of achieving a perfect fit. The CAD software's ability to pre-enlarge the design ensures that after sintering, the crown or bridge shrinks to the exact dimensions required to fit the patient's tooth preparation.

Enabling Advanced Aesthetics

After the high-temperature sintering for strength, some restorations undergo a subsequent, lower-temperature cycle for glazing. A thin layer of glass is fired onto the surface, creating a smooth, lustrous finish that mimics natural enamel and resists staining.

Understanding the Trade-offs and Considerations

While effective, the sintering process requires precision and control. Errors at this stage can compromise the entire restoration.

Time and Temperature Are Inflexible

Each type of zirconia (e.g., high-strength vs. high-translucency) has a specific, manufacturer-validated sintering cycle. This includes the rate of heating, the peak temperature, and the duration of the hold. Deviating from this protocol can result in a weak, poorly fitting, or aesthetically flawed restoration.

Shrinkage Must Be Managed

All success hinges on accurately accounting for shrinkage. The lab technician must ensure the correct shrinkage factor is programmed into the software for the specific batch of zirconia being used, as even minor variations can exist between manufacturing lots.

Furnace Calibration is Paramount

Sintering furnaces are sophisticated pieces of equipment that must be regularly calibrated to ensure they reach and hold the precise temperatures required. An inaccurate furnace is a primary source of inconsistent and failed restorations.

Applying This Knowledge to Your Goal

Understanding the role of sintering allows you to better evaluate the quality and reliability of ceramic restorations.

- If your primary focus is prescribing as a clinician: Recognize that the success of a zirconia restoration depends heavily on the dental lab's precision in the sintering process, which dictates both final fit and strength.

- If your primary focus is fabrication as a technician: Meticulously follow the manufacturer's specified sintering cycle for each zirconia disc to guarantee predictable shrinkage and achieve optimal material properties.

- If your primary focus is learning about dental materials: View sintering as the fundamental manufacturing step that unlocks zirconia's unique combination of high strength and biocompatibility for modern dental applications.

Ultimately, understanding sintering is crucial to appreciating how modern, high-strength ceramic restorations are reliably and consistently created.

Summary Table:

| Key Aspect | Description |

|---|---|

| Purpose | Transforms weak, milled zirconia into a dense, strong final restoration. |

| Typical Temperature | 1,400°C to 1,600°C. |

| Core Process | Solid-state diffusion fuses particles, eliminating pores (densification). |

| Critical Outcome | Controlled, predictable shrinkage (20-25%) for a precise fit. |

| Resulting Property | Achieves the high fracture toughness and durability zirconia is known for. |

Achieve precise, reliable sintering results for your dental lab.

KINTEK's advanced high-temperature furnaces are engineered for the exacting demands of dental zirconia sintering. With precise temperature control and uniform heating, our solutions ensure your restorations achieve optimal strength and a perfect fit, batch after batch.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Contact our experts today to discuss how we can tailor a sintering furnace solution for your laboratory's specific needs.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time