In essence, a retort furnace is used for high-temperature material processing where controlling the atmospheric environment is critical. It uses a sealed inner chamber, or retort, to isolate the material from the furnace's heating elements and outside air. This allows for precise treatments like carburizing, nitriding, sintering, and annealing, ensuring high-purity, high-quality results without contamination.

The fundamental advantage of a retort furnace is not just heat, but control. By creating a sealed, isolated environment, it allows you to dictate the exact atmospheric conditions of a thermal process, which is impossible in a standard oven.

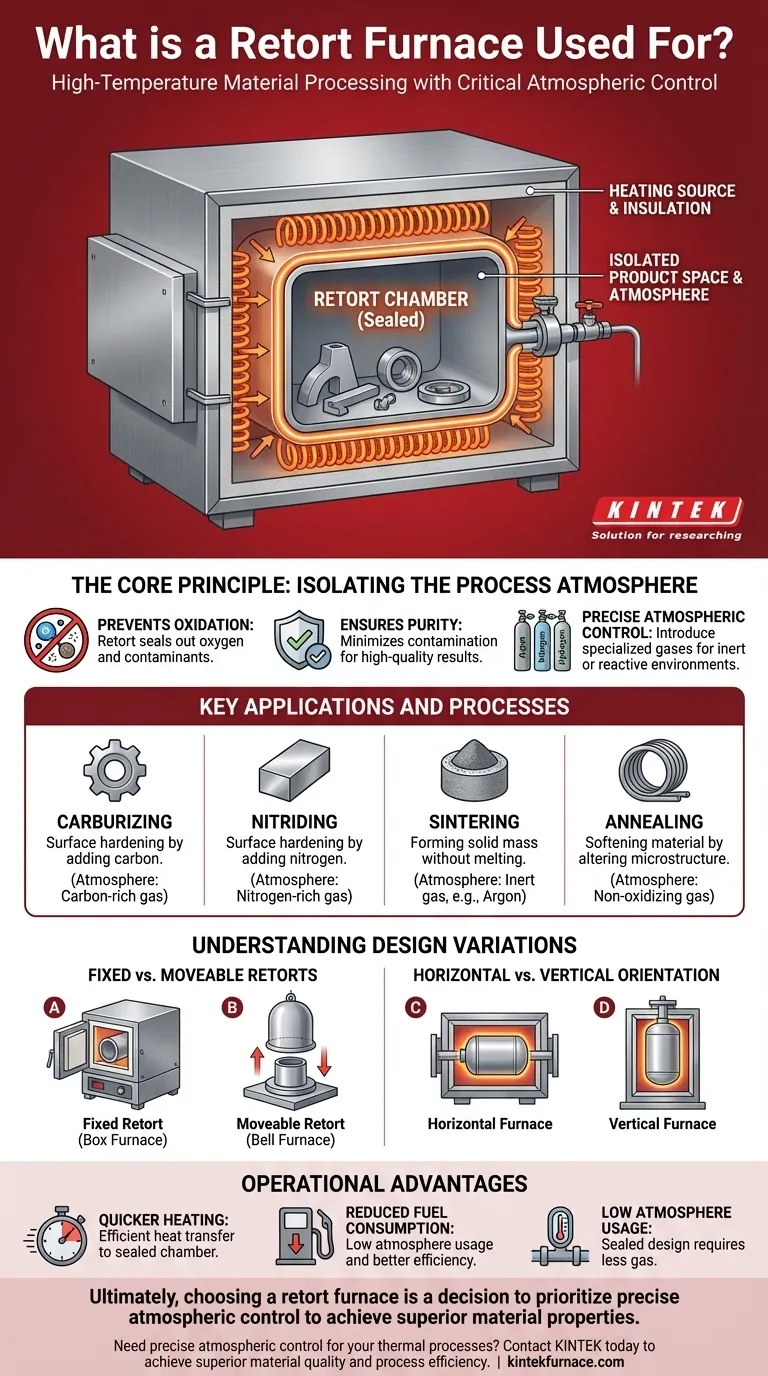

The Core Principle: Isolating the Process Atmosphere

To understand why a retort furnace is chosen, you must first understand the concept of the retort itself. It is the defining feature that separates this technology from other heating methods.

What is a Retort?

A retort is a sealed vessel, typically made of metal or ceramic, that sits inside the main furnace.

The material being treated is placed inside this retort. The furnace then heats the retort from the outside, and the heat is transferred indirectly to the material.

This design cleanly separates the product space from the heating source and the system's insulation.

Why Isolation Matters for Material Quality

Many advanced materials are highly reactive at elevated temperatures. Exposing them to oxygen or other contaminants in the air can lead to oxidation and other unwanted chemical reactions.

The sealed retort prevents this by creating a contained space. This minimizes contamination and ensures the final product meets strict quality and purity specifications.

Achieving Precise Atmospheric Control

The true power of the retort is the ability to introduce a specialized atmosphere.

Gases like Argon, Nitrogen, or Hydrogen can be pumped into the sealed retort to create an inert or reactive environment tailored to the process. Because the chamber is sealed, atmosphere usage is extremely low and efficient.

This control is essential for processes that intentionally add elements to a material's surface, such as adding carbon (carburizing) or nitrogen (nitriding).

Key Applications and Processes

The precise control over temperature and atmosphere makes retort furnaces indispensable for several key industrial processes.

Surface Hardening: Carburizing and Nitriding

These processes involve diffusing elements into the surface of a metal part to increase its hardness and durability.

A retort furnace provides the perfect environment to contain the carbon-rich or nitrogen-rich gases required for these treatments, ensuring they interact with the material surface uniformly and without contamination.

Sintering and Annealing

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. A controlled, non-oxidizing atmosphere is critical for success.

Annealing involves heating a material to alter its microstructure, typically to make it softer and more workable. Protecting the material from oxidation during this process is crucial for maintaining its surface quality.

Understanding the Design Variations

Retort furnaces are not a one-size-fits-all solution. Their design can be adapted to the specific application, footprint, and loading requirements of a facility.

Fixed vs. Moveable Retorts

A retort can be fixed within the furnace, such as in a front-loading box furnace or a top-loading pit furnace. The material is loaded directly into the stationary retort.

Alternatively, the retort can be part of a moveable system. In a bell furnace, for example, the heating chamber (the "bell") is lowered over a fixed base that holds the retort and its payload.

Horizontal vs. Vertical Orientation

Furnaces can be built in either horizontal or vertical configurations. The choice depends on the shape of the parts being processed and how they are best loaded and supported during the heating cycle.

Operational Advantages

The efficient design of a retort furnace often leads to quicker heating times due to effective heat transfer to the sealed chamber.

This efficiency, combined with the low atmosphere usage, can also result in reduced fuel consumption compared to less-controlled furnace designs.

Making the Right Choice for Your Goal

Selecting the correct thermal processing equipment depends entirely on the required outcome for your material.

- If your primary focus is maximum purity and atmospheric control: A retort furnace is the definitive choice for preventing oxidation and contamination.

- If your primary focus is surface modification (e.g., carburizing): A retort furnace is essential for containing the specific reactive gases needed for the process.

- If your primary focus is general heating without strict atmospheric needs: A simpler, direct-fired furnace without a retort may be a more cost-effective solution.

Ultimately, choosing a retort furnace is a decision to prioritize precise atmospheric control to achieve superior material properties.

Summary Table:

| Process | Key Function | Required Atmosphere |

|---|---|---|

| Carburizing | Surface hardening by adding carbon | Carbon-rich gas |

| Nitriding | Surface hardening by adding nitrogen | Nitrogen-rich gas |

| Sintering | Forming solid mass without melting | Inert gas (e.g., Argon) |

| Annealing | Softening material by altering microstructure | Non-oxidizing gas |

Need precise atmospheric control for your thermal processes? KINTEK's expertise in high-temperature furnace solutions is your answer. Leveraging exceptional R&D and in-house manufacturing, we provide advanced retort furnaces and a full product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for carburizing, nitriding, sintering, and more. Contact us today to achieve superior material quality and process efficiency. Get in touch

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing