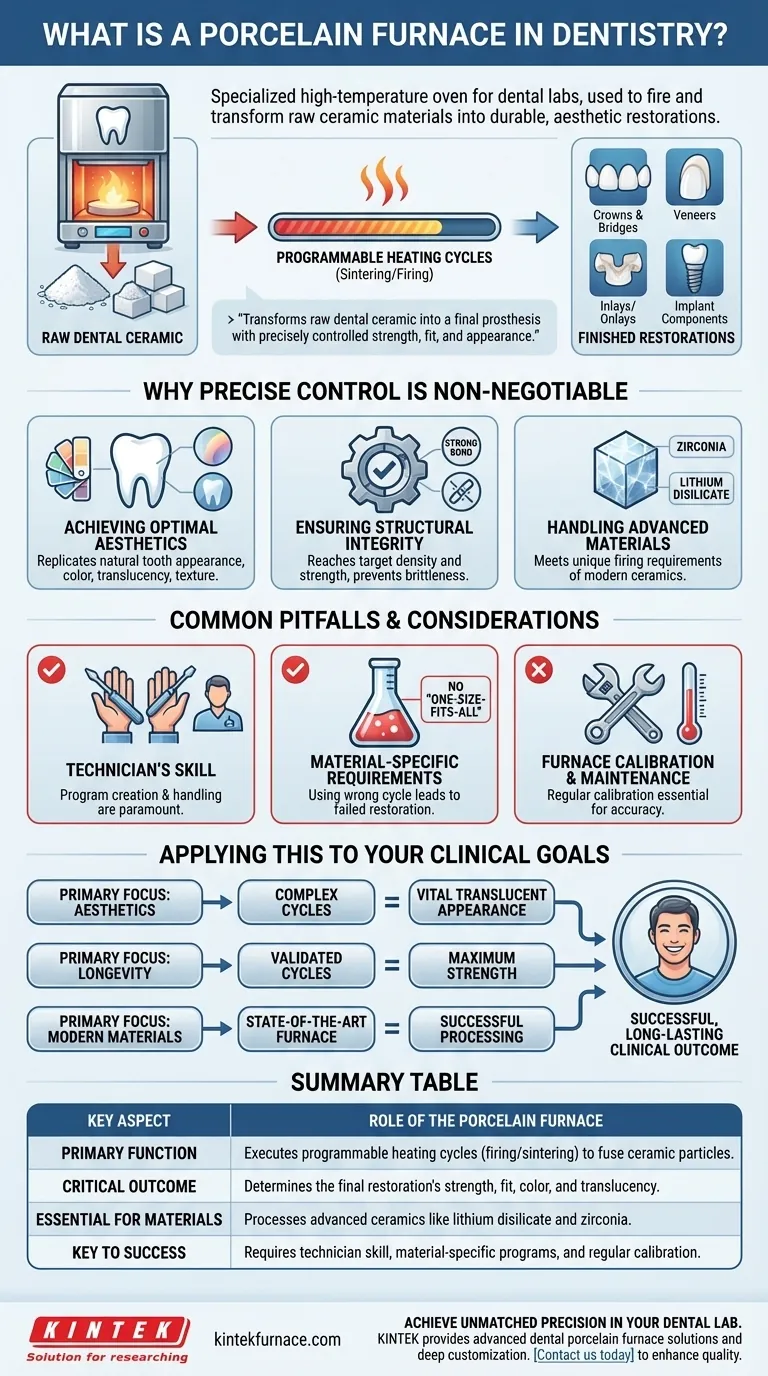

In simple terms, a porcelain furnace is a specialized, high-temperature oven used in dental laboratories to fire ceramic materials. These sophisticated, electronically controlled devices are essential for fabricating durable and aesthetically pleasing dental restorations such as crowns, bridges, and veneers.

A porcelain furnace is more than just a heating device; it is the critical tool that transforms raw dental ceramic into a final prosthesis with precisely controlled strength, fit, and appearance, making it indispensable to modern restorative dentistry.

The Core Function: From Raw Ceramic to Finished Restoration

A porcelain furnace executes highly specific, programmable heating cycles. This process, known as firing or sintering, is what gives a dental restoration its final properties.

What It Does

The furnace heats raw dental porcelain or ceramic materials to precisely controlled temperatures over a specific period. This fuses the ceramic particles together, hardening the material and maturing it to its optimal state.

What It Creates

Technicians use porcelain furnaces to create a wide range of custom restorations, including:

- Crowns and bridges

- Veneers

- Inlays and onlays

- Dental implant components

The Importance of Programmable Cycles

Modern furnaces do not simply heat to one temperature. They run complex, pre-programmed cycles with multiple stages of heating, holding, and cooling, which are tailored to the specific material being used.

Why Precise Control is Non-Negotiable

The quality of the final restoration is directly dependent on the precision of the firing cycle. This control is what separates a lifelike, durable prosthesis from one that is weak, opaque, or ill-fitting.

Achieving Optimal Aesthetics

The furnace's precise control over the firing process is what allows a skilled technician to replicate the appearance of a natural tooth. It directly influences key properties like translucency, color (hue and chroma), and surface texture.

Ensuring Structural Integrity

An incorrect firing cycle can result in a restoration that is brittle, porous, or prone to fracture. The furnace ensures the ceramic reaches its target density and strength, making it durable enough for long-term clinical function.

Handling Advanced Materials

Modern dentistry relies on advanced materials like lithium disilicate and zirconia. Each has unique and demanding firing requirements that can only be met by a sophisticated, programmable porcelain furnace.

Common Pitfalls and Considerations

While the furnace is a critical tool, its effectiveness is not automatic. Achieving consistent, high-quality results depends on understanding and managing several key factors.

The Technician's Skill

A furnace is only as good as the technician operating it. Creating the correct firing program and properly handling the restoration before it enters the furnace are paramount to success.

Material-Specific Requirements

There is no "one-size-fits-all" firing cycle. Using a program designed for one type of ceramic on another will lead to a failed restoration. Each material from each manufacturer has its own validated protocol.

Furnace Calibration and Maintenance

These are precision instruments that require regular maintenance and calibration. An uncalibrated furnace can deviate from the programmed temperature, introducing a major source of error and inconsistent results.

Applying This to Your Clinical Goals

Understanding the role of the porcelain furnace helps connect the laboratory process to the clinical outcome.

- If your primary focus is aesthetics: The furnace's ability to execute complex cycles is what creates the vital, translucent appearance of a high-end ceramic restoration.

- If your primary focus is longevity: A properly calibrated furnace running a validated firing cycle is your best guarantee for a restoration with maximum strength and fracture resistance.

- If your primary focus is using modern materials: A state-of-the-art porcelain furnace is an absolute prerequisite for successfully processing advanced ceramics like lithium disilicate.

Ultimately, the porcelain furnace is the crucial bridge between the raw dental material and a successful, long-lasting clinical outcome for the patient.

Summary Table:

| Key Aspect | Role of the Porcelain Furnace |

|---|---|

| Primary Function | Executes programmable heating cycles (firing/sintering) to fuse ceramic particles. |

| Critical Outcome | Determines the final restoration's strength, fit, color, and translucency. |

| Essential for Materials | Processes advanced ceramics like lithium disilicate and zirconia. |

| Key to Success | Requires technician skill, material-specific programs, and regular calibration. |

Achieve Unmatched Precision in Your Dental Lab

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides dental laboratories with advanced high-temperature furnace solutions. Our product line, including specialized dental porcelain furnaces, is complemented by our strong deep customization capability to precisely meet your unique material and workflow requirements.

Contact us today to discuss how our furnaces can enhance the quality and consistency of your crowns, bridges, and veneers.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations