At its core, a dental furnace is a high-temperature oven used to process ceramic materials like porcelain and zirconia into their final, hardened state. It is an essential piece of equipment in any dental laboratory for creating durable and aesthetic dental restorations, including crowns, bridges, veneers, and inlays.

A dental furnace is not simply an oven; it is a precision instrument. Its primary function is to transform raw, workable dental materials into final, high-strength prosthetics by applying meticulously controlled heat, and sometimes pressure, over a specific period.

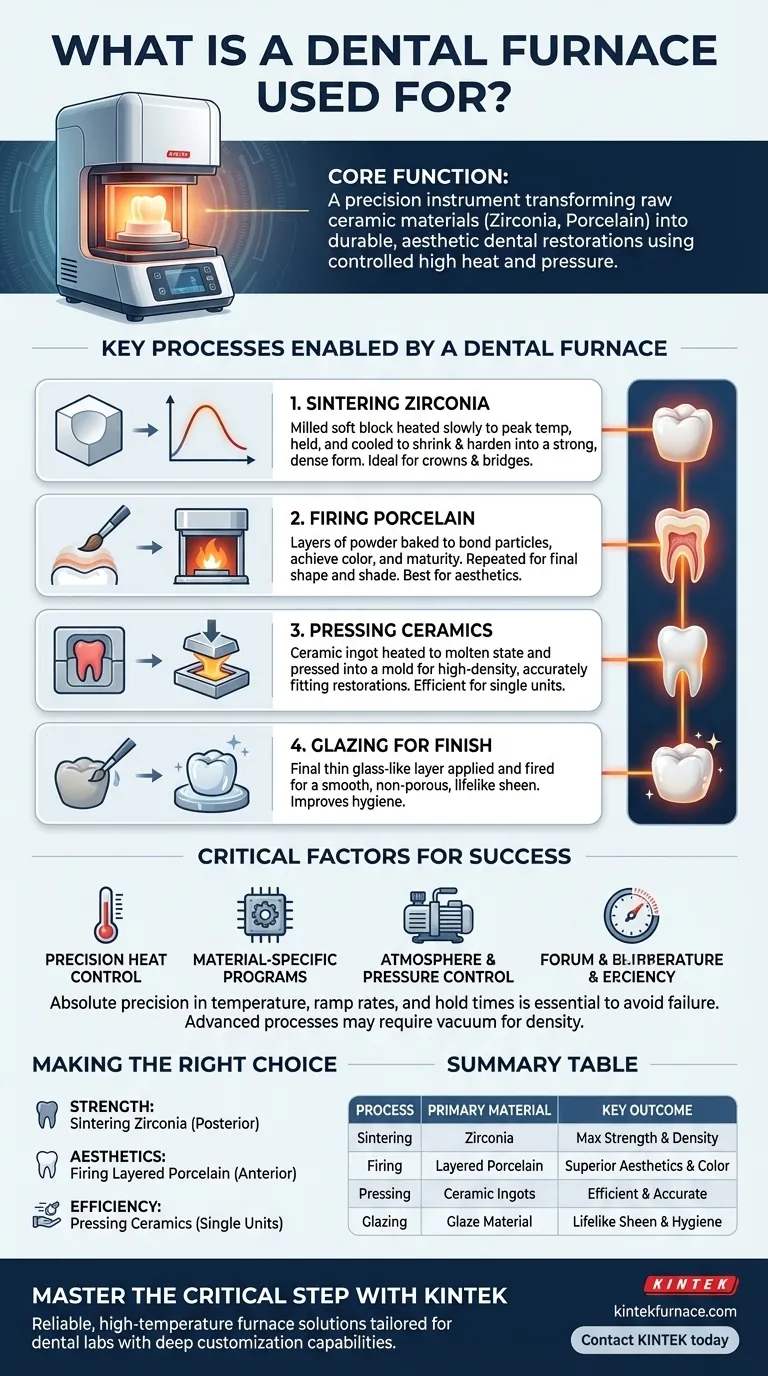

The Core Function: From Raw Material to Final Restoration

A dental furnace is the critical link between a digitally designed or manually shaped restoration and the final product that can be placed in a patient's mouth. The process fundamentally alters the material's physical properties.

Transforming Ceramic Materials

Restorations often begin as a soft, chalk-like block of zirconia or layers of porcelain powder. In this initial state, the material is easy to mill or shape but lacks the necessary strength and aesthetic properties for clinical use.

The Role of Extreme Heat

The furnace applies precisely controlled heat, often exceeding 1,500°C (2,732°F). This thermal energy causes the particles within the ceramic to fuse together, densify, and crystallize, transforming the weak pre-sintered form into a hard, durable, and permanent restoration.

Key Processes Enabled by a Dental Furnace

Different materials and desired outcomes require specific heating programs. A furnace is designed to execute these processes with high accuracy.

Sintering Zirconia

Sintering is the primary process used for zirconia restorations. After a crown or bridge is milled from a zirconia block, it is placed in the furnace. The sintering cycle heats the material slowly to a specific peak temperature, holds it there, and then cools it down, causing it to shrink and harden into a dense, incredibly strong final form.

Firing Porcelain

Porcelain restorations are often built up in layers of powder mixed with a liquid. Each layer is "fired" in the furnace to bake the particles together, achieving proper bonding, maturity, and color. This process is repeated until the restoration's final shape and shade are achieved.

Pressing Ceramics

For pressed ceramic restorations, a wax model of the restoration is created and encased in an investment material. This is then placed in a pressing furnace. A ceramic ingot is heated until molten and then pressed into the mold, creating a very dense and accurately fitting restoration.

Glazing for a Final Finish

Glazing is the final step for most ceramic restorations. The restoration is coated with a thin layer of glass-like material and briefly fired in the furnace. This creates a smooth, non-porous, and lifelike sheen on the surface, improving both aesthetics and hygiene.

Understanding the Critical Factors and Trade-offs

The success of a ceramic restoration is directly dependent on the quality and accuracy of the heat treatment process. Mismanagement at this stage is a common source of failure.

The Need for Absolute Precision

Inconsistent or inaccurate temperatures can ruin a restoration. If the heat is too low, the material won't fully sinter or mature, resulting in a weak product. If it's too high, the material can melt, lose its shape, or become discolored, wasting significant time and cost.

Material-Specific Programs

There is no one-size-fits-all heating cycle. Different ceramic systems (e.g., zirconia versus lithium disilicate versus layered porcelain) have unique requirements for ramp rates (how fast the temperature rises), hold times, and peak temperatures. The furnace must be programmable to handle this variability.

Atmosphere and Pressure Control

Some advanced processes require not just temperature control but also pressure or a vacuum. A vacuum is often used during porcelain firing to remove air bubbles and increase the final density and translucency of the material.

Making the Right Choice for Your Process

The specific furnace process you use is determined by the material selected and the clinical demands of the restoration.

- If your primary focus is maximum strength: Sintering zirconia is the essential process for creating robust posterior crowns and multi-unit bridges.

- If your primary focus is high-end aesthetics: Firing layered porcelain is critical for achieving the nuanced translucency and color depth required for anterior veneers and crowns.

- If your primary focus is efficiency and accuracy for single units: Pressing ceramics provides a highly reliable and repeatable method for fabricating well-fitting inlays, onlays, and crowns.

Ultimately, mastering the use of a dental furnace is fundamental to producing consistent, high-quality ceramic restorations.

Summary Table:

| Process | Primary Material | Key Outcome |

|---|---|---|

| Sintering | Zirconia | Maximum strength & density for crowns/bridges |

| Firing | Layered Porcelain | Superior aesthetics & color for veneers/crowns |

| Pressing | Ceramic Ingots | Efficient, accurate single-unit restorations |

| Glazing | Glaze Material | Lifelike sheen & improved hygiene |

Master the final, most critical step in creating perfect dental restorations.

At KINTEK, we understand that your furnace is the heart of your dental lab. Leveraging exceptional R&D and in-house manufacturing, we provide advanced, high-temperature furnace solutions tailored for dental laboratories. Our product line, including precise sintering and pressing furnaces, is complemented by our strong deep customization capability to precisely meet your unique material and workflow requirements.

Contact KINTELK today to discuss how our reliable dental furnaces can enhance the strength, aesthetics, and consistency of your crowns, bridges, and veneers.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency