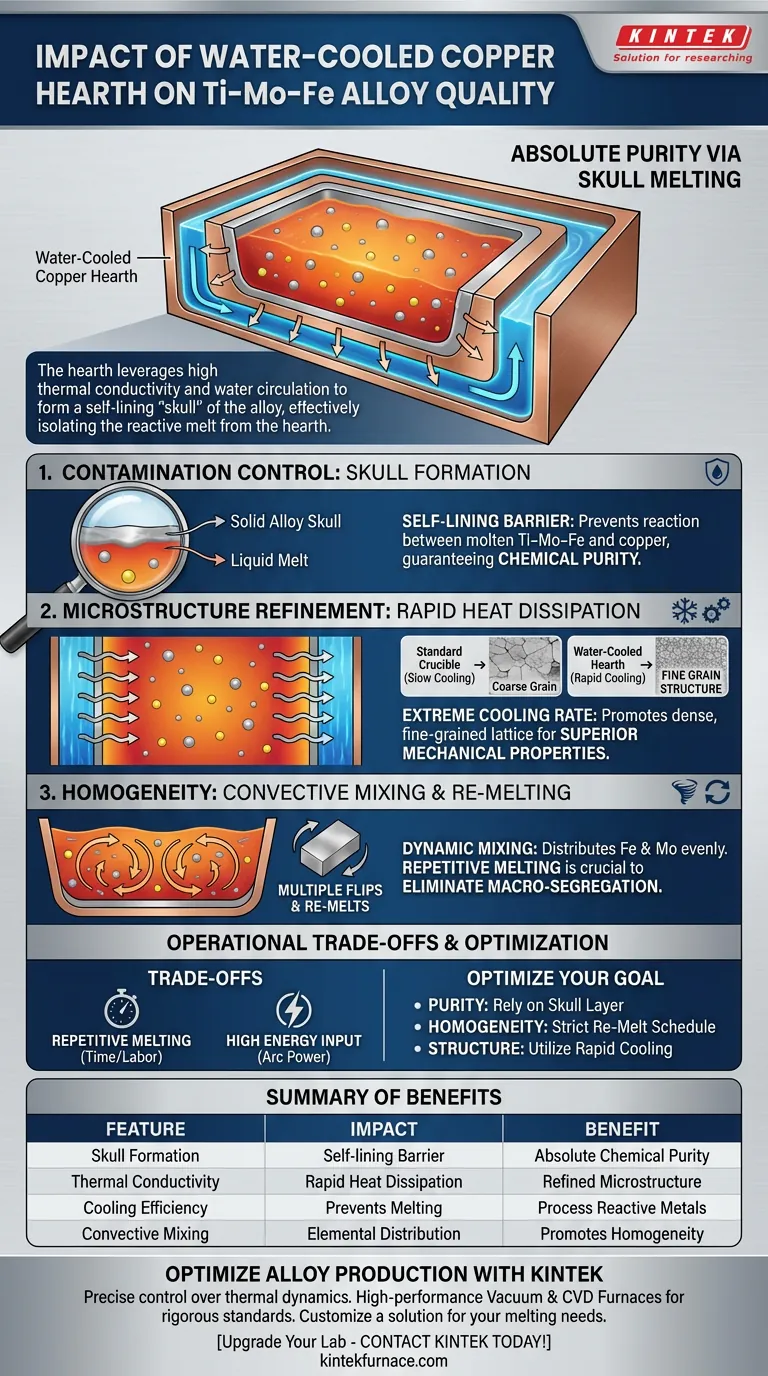

The primary impact of a water-cooled copper hearth is the absolute preservation of alloy purity. By leveraging the high thermal conductivity of copper and active water circulation, the hearth forces a thin, solid shell of the Ti–Mo–Fe alloy to form at the contact interface. This "skull" acts as a physical barrier, effectively isolating the reactive molten mixture from the hearth material to prevent contamination.

The water-cooled copper hearth enables a "skull melting" process where the alloy creates its own crucible lining. This ensures the high-temperature melt never reacts with the containment vessel, guaranteeing chemical purity while facilitating rapid cooling for refined microstructures.

The Mechanism of Contamination Control

Formation of the Solid Skull

The core function of the hearth is to generate a "skull"—a thin layer of the alloy that solidifies immediately upon contact with the cooled copper surface. Because copper conducts heat efficiently and is actively water-cooled, it extracts heat rapidly from the alloy's outer layer. This creates a self-lining container, ensuring the liquid metal sits inside a solid shell of its own composition rather than touching the copper directly.

Preventing High-Temperature Reactions

Titanium and Molybdenum have high melting points and are highly reactive in their molten states. Without the skull layer, these elements could react with the hearth material, introducing foreign impurities into the matrix. The water-cooled hearth eliminates this risk, ensuring the chemical composition of the final Ti–Mo–Fe alloy remains accurate.

Thermal Dynamics and Microstructure

Rapid Heat Dissipation

Beyond purity, the water-cooled hearth acts as an aggressive heat sink. It draws thermal energy away from the molten pool much faster than a standard ceramic crucible would. This capability is critical for controlling the solidification process of high-melting-point powders.

Refinement of Microstructure

The extreme cooling rate provided by the hearth influences the final structure of the material. Fast cooling facilitates the formation of fine solidified microstructures. This is generally desirable, as a finer grain structure often leads to superior mechanical properties in the final alloy.

Ensuring Homogeneity Through Process

The Role of Convection

While the hearth cools the exterior, the interior molten pool remains dynamic. Under the influence of arc forces and gravity, the liquid alloy undergoes convective mixing. This natural movement helps distribute elements like Iron (Fe) and Molybdenum (Mo) evenly throughout the Titanium (Ti) base.

Addressing Macro-Segregation

Despite convective mixing, the rapid cooling at the bottom of the hearth can trap inhomogeneities. To counter this, the process requires multiple flipping and re-melting cycles. This ensures that every part of the ingot is exposed to the arc and undergoes the necessary mixing to eliminate macro-segregation.

Operational Considerations and Trade-offs

The Necessity of Repetitive Melting

The hearth's cooling efficiency is a double-edged sword: it protects the alloy but can cause the bottom layer to solidify before it is fully mixed. Consequently, a single melt is rarely sufficient. Achieving high chemical homogeneity requires a rigorous protocol of flipping the ingot and re-melting it multiple times.

Energy Balance Requirements

Because the hearth is actively removing heat to maintain the skull, the system requires significant energy input (via the arcs) to keep the core molten. This dynamic balance must be carefully managed to ensure the powders melt completely without melting the protective copper hearth beneath the skull.

Making the Right Choice for Your Goal

How to Apply This to Your Project

- If your primary focus is Chemical Purity: Rely on the water-cooled hearth to maintain the "skull" layer, ensuring no interaction occurs between the melt and the copper substrate.

- If your primary focus is Structural Homogeneity: You must account for the hearth's rapid cooling by implementing a strict schedule of multiple flips and re-melts to prevent segregation.

- If your primary focus is Microstructural Refinement: Utilize the high cooling rate of the copper hearth to drive rapid solidification, promoting a dense and fine-grained lattice.

The water-cooled copper hearth is not merely a container; it is an active processing tool that dictates both the purity and the physical structure of the final Ti–Mo–Fe alloy.

Summary Table:

| Feature | Impact on Ti–Mo–Fe Alloy Quality | Benefit to Final Product |

|---|---|---|

| Skull Formation | Creates a self-lining barrier of solid alloy | Ensures absolute chemical purity; no contamination |

| Thermal Conductivity | Rapid heat dissipation from the molten pool | Refines microstructure and creates finer grain size |

| Cooling Efficiency | Active water circulation prevents hearth melting | Allows processing of high-melting-point reactive metals |

| Convective Mixing | Dynamic movement of Mo and Fe in Ti base | Promotes elemental homogeneity (requires re-melting) |

Optimize Your Advanced Alloy Production with KINTEK

Precise control over thermal dynamics is the key to mastering reactive alloys like Ti–Mo–Fe. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Vacuum, CVD, and customizable high-temp furnace systems designed to meet the most rigorous lab and industrial standards.

Whether you need to refine microstructures or ensure absolute chemical purity, our engineers are ready to help you customize a solution for your unique melting needs.

Upgrade your lab's efficiency—Contact KINTEK today!

Visual Guide

References

- Nthabiseng Moshokoa, Maje Phasha. Influence of intermetallic phase (TiFe) on the microstructural evolution and mechanical properties of as-cast and quenched Ti–Mo–Fe alloys. DOI: 10.1038/s41598-024-60894-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Induction Melting Furnace

People Also Ask

- What are the key advantages of using induction furnaces for metal casting? Boost Efficiency and Quality in Your Foundry

- Can aluminium be melted in an induction furnace? Discover the Efficient, High-Quality Method

- What additional features might advanced induction heater circuits incorporate? Enhance Precision, Efficiency, and Safety

- What is a vacuum induction furnace and how does it differ from other vacuum sintering furnaces? Discover the Key Differences

- What is the role of a Vacuum Induction Melting (VIM) furnace in Invar 36 production? Ensure Purity & Precision

- What is the function of the water-cooled copper crucible? Ensure Absolute Purity in Vacuum Arc Melting

- Why are induction gold melting furnaces considered cost-effective in the long run? A Smart Investment for Higher Profits

- Why does the preparation of high-entropy alloys require a vacuum arc furnace? Ensure Homogeneity & Purity.