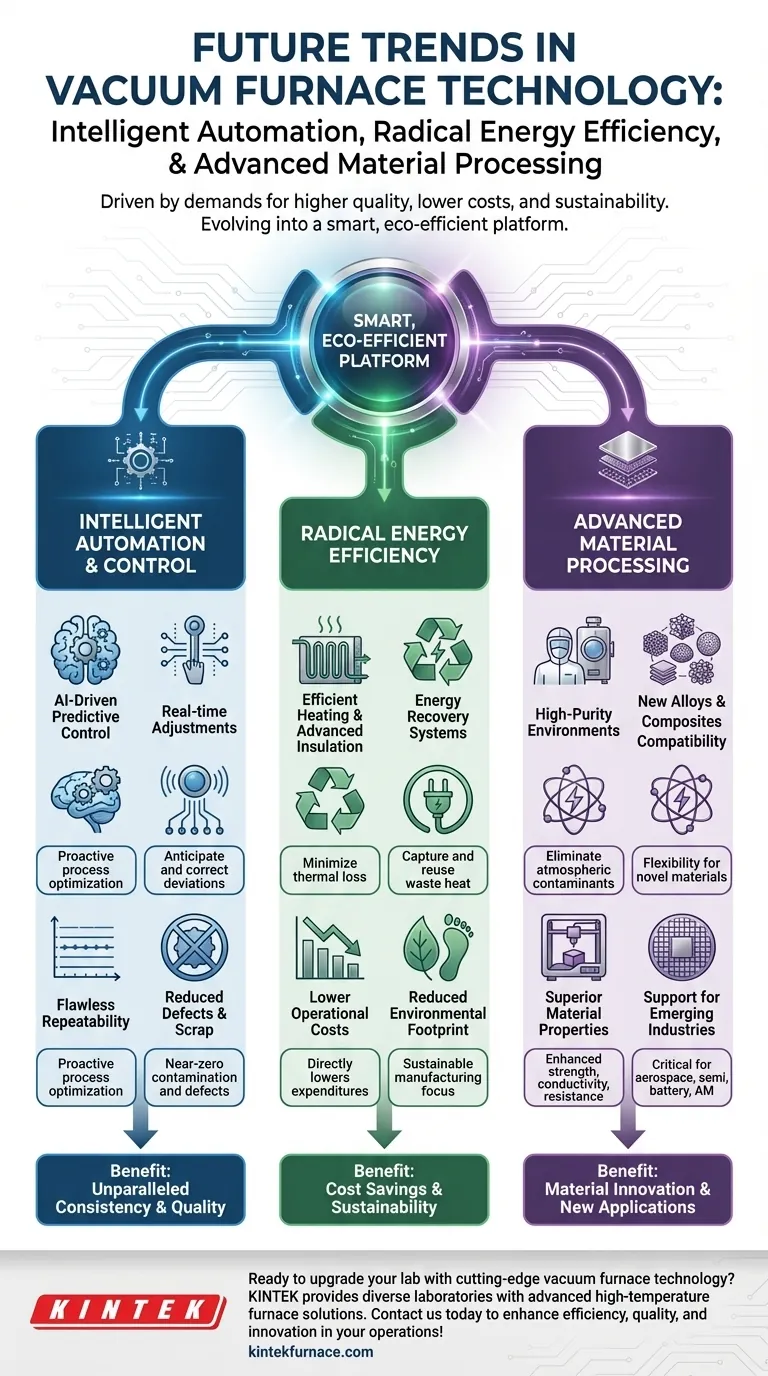

In short, the future of vacuum furnace technology is driven by three interconnected trends: intelligent automation, radical energy efficiency, and the processing of next-generation advanced materials. These advancements are a direct response to industrial demands for higher quality, lower operational costs, and greater sustainability. The core function of the vacuum furnace is evolving from a simple controlled environment into a smart, eco-efficient platform for material innovation.

The evolution of vacuum furnace technology is no longer just about achieving a better vacuum. It's about creating an intelligent, sustainable processing environment that unlocks new material possibilities while reducing both operational and environmental costs.

The Drive for Sustainability and Efficiency

The increasing pressure for sustainable manufacturing is fundamentally reshaping vacuum furnace design. The focus is shifting from pure performance to performance-per-watt, minimizing both energy consumption and environmental footprint.

Reducing Energy Consumption

Future furnaces are being designed with highly efficient heating methods and advanced insulation. These systems minimize thermal loss, directly reducing the significant energy required to reach and maintain high processing temperatures.

This move toward efficiency is not just about environmental responsibility; it directly lowers operational expenditures, making a strong business case for upgrading older, less efficient equipment.

The Role of Energy Recovery

A key area of innovation is the development of more effective energy recovery systems. These systems capture and reuse waste heat from the cooling cycles, which would otherwise be lost to the atmosphere.

This captured energy can be redirected to pre-heat subsequent loads or used for other plant utilities, creating a more circular and cost-effective energy loop within the facility.

The Rise of Intelligent Process Control

While automation has long been a feature of vacuum furnaces for ensuring process repeatability, the next wave of innovation lies in the integration of artificial intelligence (AI) and machine learning.

From Automation to Predictive Control

Simple automation follows a pre-programmed set of instructions. AI-driven systems, however, learn from sensor data across thousands of cycles to predict outcomes and make real-time adjustments.

This "predictive control" can anticipate and correct for minor deviations before they impact the final product, moving from reactive adjustments to proactive process optimization.

The Goal: Flawless Repeatability

For industries like aerospace and medical manufacturing, part-to-part consistency is non-negotiable. Intelligent control systems eliminate the last vestiges of process variability, ensuring every batch meets exact specifications.

This level of control ensures unparalleled material purity and structural integrity, reducing contamination and defects to near-zero levels.

Expanding the Frontiers of Material Science

Vacuum furnaces are the enabling technology behind many of today's most advanced materials. Future trends will see them become even more critical as they are adapted for new alloys, composites, and manufacturing processes.

Enabling Emerging Industries

Industries like semiconductor manufacturing, advanced battery production, and additive manufacturing (3D printing) rely on the ultra-clean, controlled environment that only a vacuum furnace can provide.

Future furnaces will be designed with enhanced compatibility for these novel materials and processes, offering greater flexibility and control over their unique thermodynamic properties.

Improving Purity and Performance

The core benefit of a vacuum is the elimination of atmospheric contaminants that can compromise material properties. Future advancements will focus on achieving even higher vacuum levels and greater control over trace elements.

This push for ultimate purity allows for the creation of materials with superior strength, conductivity, and thermal resistance, opening doors to new applications and higher-performance products.

Understanding the Trade-offs

Adopting next-generation vacuum furnace technology involves clear advantages, but it is critical to understand the associated challenges.

The Upfront Capital Investment

Advanced furnaces with AI integration and energy recovery systems carry a higher initial purchase price. This cost must be weighed against the long-term benefits of lower energy bills, reduced scrap rates, and improved product quality.

The Complexity of Integration

Smarter systems are inherently more complex. Integrating an AI-driven furnace into an existing production line requires careful planning and may necessitate new data infrastructure and control protocols.

The Need for New Skills

Operating and maintaining these sophisticated systems requires a workforce with skills in data analysis and advanced mechatronics, not just traditional furnace operation. A potential skills gap must be considered and addressed through training.

Making the Right Choice for Your Goal

The best path forward depends entirely on your organization's primary strategic objective.

- If your primary focus is operational cost reduction and sustainability: Prioritize furnaces with documented high-efficiency heating elements and integrated energy recovery systems.

- If your primary focus is ultimate quality and process repeatability: Look for systems with advanced sensor packages and AI-driven predictive control to minimize defects and ensure consistency.

- If your primary focus is research and development of new materials: Select a furnace designed for maximum flexibility, high-purity processing, and compatibility with a wide range of exotic materials.

By understanding these core trends, you can make strategic investments that position your operations to not only meet today's demands but also lead in the material innovations of tomorrow.

Summary Table:

| Trend | Key Features | Benefits |

|---|---|---|

| Intelligent Automation | AI-driven predictive control, real-time adjustments | Flawless repeatability, reduced defects, proactive optimization |

| Energy Efficiency | Efficient heating methods, advanced insulation, energy recovery systems | Lower operational costs, reduced environmental footprint |

| Advanced Material Processing | High-purity environments, compatibility with new alloys and composites | Superior material properties, support for emerging industries |

Ready to upgrade your lab with cutting-edge vacuum furnace technology? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance efficiency, quality, and innovation in your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control