Choosing the right material for a muffle furnace is a critical decision that directly impacts the success, safety, and longevity of your thermal processing work. The selection is governed by your specific experimental requirements, focusing on maximum temperature, chemical compatibility, and desired heating characteristics. The three primary materials for furnace construction—quartz, ceramic, and metal—each offer a distinct set of properties tailored for different applications.

Your choice of furnace material is not just about reaching a target temperature. It's a strategic decision that balances thermal performance against chemical resistance, defining the furnace's suitability for your specific process and ensuring the integrity of your results.

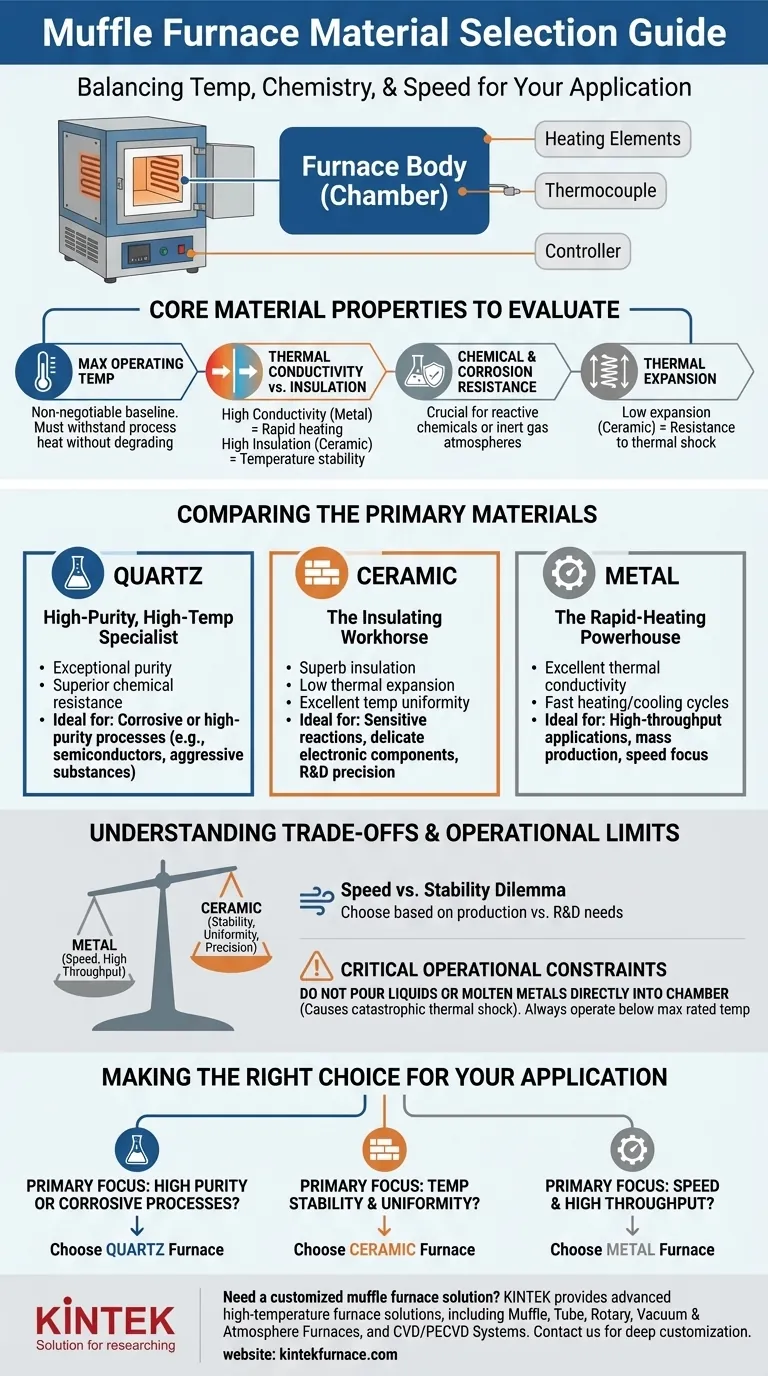

Deconstructing the Furnace: Core Components

A muffle furnace is a system of coordinated parts, but the furnace body, or chamber, is the component that demands the most careful material consideration. It is the vessel that contains the heat and interacts directly with your sample.

The Furnace Body: The Heart of the System

The furnace body is constructed from materials designed to withstand extreme heat and, in many cases, corrosive environments. This is the primary material you are selecting when comparing different furnace models.

Key Internal Components

While the body is your main focus, other components enable its function. Heating elements (like silicon carbide rods or platinum tungsten wire) generate the heat, and thermocouples measure the temperature. A controller uses this feedback to regulate power to the heating elements, maintaining a precise temperature.

Core Material Properties to Evaluate

Your selection process should begin by filtering options based on four fundamental material properties. These factors determine whether a furnace is appropriate for your application.

Maximum Operating Temperature

This is the non-negotiable starting point. The furnace material must be able to operate safely at your required process temperatures without degrading, melting, or becoming compromised.

Thermal Conductivity vs. Insulation

This property defines how the furnace behaves during heating and cooling. High thermal conductivity (like metal) allows for very rapid heating, while high insulation (like ceramic) provides excellent temperature stability and uniformity but at the expense of speed.

Chemical and Corrosion Resistance

The furnace chamber must remain inert and not react with your sample or any process atmospheres (e.g., inert gases). A material's resistance to corrosion is critical for applications involving reactive chemicals or high-temperature oxidation.

Thermal Expansion

Materials expand when heated and contract when cooled. A material with low thermal expansion, such as ceramic, is more resistant to cracking or damage from rapid temperature changes (thermal shock), ensuring greater stability and a longer service life.

Comparing the Primary Furnace Materials

With the core properties understood, we can evaluate the three main material classes. Each represents a different balance of these characteristics.

Quartz: The High-Purity, High-Temp Specialist

Quartz is a type of glass with exceptional purity. Its key advantage is superior resistance to high temperatures and chemical corrosion. It is an ideal choice for processes where contamination is a major concern or when working with aggressive substances.

Ceramic: The Insulating Workhorse

Ceramic materials are prized for their superb insulation and low thermal expansion. This combination results in excellent temperature uniformity and stability within the chamber, making them perfect for sensitive chemical reactions or processing delicate electronic components.

Metal: The Rapid-Heating Powerhouse

Metal-bodied furnaces, typically using high-temperature alloys, offer excellent thermal conductivity. This allows them to heat up and cool down much faster than ceramic or quartz furnaces, making them the preferred choice for high-throughput applications and mass production.

Understanding the Trade-offs and Operational Limits

Selecting the right material requires acknowledging its inherent limitations and adhering to proper operating procedures.

The Speed vs. Stability Dilemma

The most common trade-off is between a metal and a ceramic furnace. A metal furnace provides speed, essential for production environments. A ceramic furnace provides stability, which is critical for research and development where precision and uniformity are paramount.

The Cost of Extreme Performance

Specialty materials like high-purity quartz command a higher price. While essential for certain applications, choosing it when not required can lead to unnecessary expense. Match the material to the need, not just the highest specification.

Critical Operational Constraints

Regardless of the material, all muffle furnaces have universal rules for longevity. It is forbidden to pour liquids or molten metals directly into the chamber, as this can cause catastrophic thermal shock and damage. Always operate below the maximum rated temperature to ensure a long service life.

Making the Right Choice for Your Application

Use your primary process goal as the final filter to select the ideal furnace material.

- If your primary focus is high-purity or corrosive processes: Choose a quartz furnace for its superior chemical inertness and high-temperature resistance.

- If your primary focus is temperature stability and uniformity: A ceramic furnace is the ideal choice due to its excellent insulation and low thermal expansion.

- If your primary focus is speed and high throughput: Select a metal-bodied furnace for its rapid heating and cooling cycles suited for production environments.

Aligning the furnace material with your specific experimental needs is the single most important step toward achieving reliable and repeatable results.

Summary Table:

| Material | Max Temp | Key Properties | Best For |

|---|---|---|---|

| Quartz | High | High purity, excellent chemical resistance | High-purity or corrosive processes |

| Ceramic | High | Superior insulation, low thermal expansion | Temperature stability and uniformity |

| Metal | High | Rapid heating, high thermal conductivity | Speed and high throughput |

Need a customized muffle furnace solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to enhance your thermal processing efficiency and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency