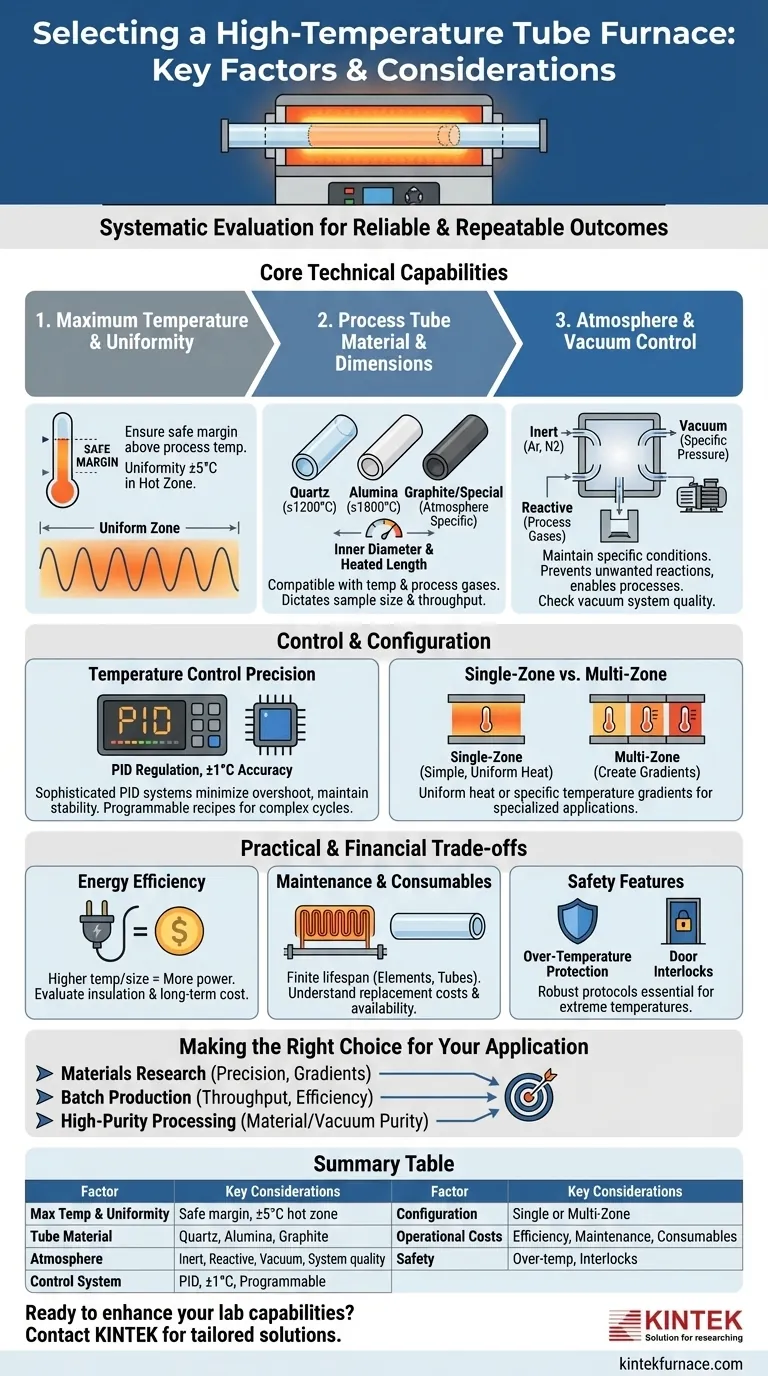

Selecting the right high-temperature tube furnace requires a systematic evaluation of its core technical capabilities. The most critical factors are the furnace's maximum operating temperature, the material and dimensions of the process tube, and its ability to precisely control the internal atmosphere, whether that is inert gas, a reactive gas, or a vacuum.

A tube furnace is not merely a heater; it is a controlled process environment. The optimal choice is not the one with the highest specifications, but the one whose temperature uniformity, material compatibility, and atmospheric controls are precisely matched to ensure the reliability and repeatability of your specific application.

Deconstructing the Core Specifications

The foundation of your decision rests on matching the furnace's hardware to the physical and chemical demands of your work. Getting these three areas right is non-negotiable.

Maximum Temperature and Uniformity

Your first filter is the required temperature range. Ensure the furnace's maximum continuous operating temperature provides a safe margin above your highest process temperature.

However, maximum temperature alone is insufficient. Temperature uniformity, or the consistency of temperature across the heated length of the tube, is what guarantees consistent results for your entire sample. A specification like ±5°C indicates how much the temperature can vary within the central "hot zone."

Process Tube Material and Dimensions

The process tube contains your sample and atmosphere, making its material a critical choice. The material must be compatible with your maximum temperature and chemically inert to your sample and process gases.

- Quartz: Cost-effective and common, but typically limited to around 1100-1200°C.

- Alumina: A ceramic that offers higher temperature resistance (often up to 1700-1800°C) and good chemical stability.

- Graphite/Other: Used for specialized applications, often involving specific non-oxidizing atmospheres.

The tube's inner diameter and heated length dictate your sample size or batch throughput. A larger diameter allows for bigger samples, but may pose challenges for achieving perfect temperature uniformity.

Atmosphere and Vacuum Control

The furnace must be able to create and maintain the specific atmospheric conditions your process requires. This is essential for preventing unwanted reactions like oxidation or enabling specific chemical vapor deposition processes.

Your needs will fall into one of three categories:

- Inert Atmosphere: Flowing gases like Argon or Nitrogen to protect the sample.

- Reactive Atmosphere: Introducing specific gases that are part of the chemical process.

- Vacuum: Removing atmosphere to a specific pressure level. The quality of the vacuum system and seals determines the ultimate vacuum achievable.

The Brains of the Operation: Control and Configuration

Beyond the core hardware, the furnace's control system determines its precision, repeatability, and ease of use.

Temperature Control Precision

Modern furnaces use sophisticated temperature control systems to ensure accuracy. Look for features like PID (Proportional-Integral-Derivative) regulation, which minimizes temperature overshoot and maintains stability.

The controller's precision determines process repeatability. A display accuracy of ±1°C is a common benchmark for high-quality systems, allowing you to run identical thermal cycles with confidence. Programmable controllers that can store multi-step recipes are invaluable for complex processes.

Single-Zone vs. Multi-Zone Designs

Tube furnaces come in two primary configurations:

- Single-Zone: A single heating element and control system. This is ideal for processes that require a simple, uniform hot zone.

- Multi-Zone: Multiple independent heating elements and controllers along the length of the tube. This advanced feature allows you to create specific temperature gradients, which is essential for applications like crystal growth or specialized chemical vapor transport.

Understanding the Practical and Financial Trade-offs

A furnace is a long-term investment. Evaluating its operational realities is just as important as its technical specifications.

Energy Efficiency and Operational Costs

Higher temperatures and larger chambers demand significantly more power. Evaluating the energy efficiency of a furnace, including its insulation quality, can reveal its true long-term operational cost. This is a critical factor for production environments.

Maintenance and Consumables

Heating elements and process tubes are consumables with a finite lifespan. Their longevity is impacted by operating temperature, heating/cooling rates, and the chemical environment. Understand the replacement cost and availability of these parts.

Safety Features

Operating at extreme temperatures requires robust safety protocols. Essential safety features include over-temperature protection, which automatically shuts down the furnace if it exceeds a set limit, and door interlocks that cut power when the furnace is opened.

Making the Right Choice for Your Application

Select a furnace by aligning its capabilities with your primary goal.

- If your primary focus is fundamental materials research: Prioritize precision temperature control, multi-zone options for creating gradients, and versatile atmosphere/vacuum capabilities.

- If your primary focus is batch production or annealing: Emphasize tube diameter for throughput, temperature uniformity across the entire heated length, and energy efficiency to manage operational costs.

- If your primary focus is high-purity processing or crystal growth: Focus on the purity of the tube material (e.g., high-purity alumina) and the performance of the vacuum system.

A well-chosen furnace becomes a reliable partner in achieving precise and repeatable outcomes.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Maximum Temperature & Uniformity | Ensure safe margin above process temp; look for ±5°C uniformity in hot zone |

| Process Tube Material | Quartz (up to 1200°C), Alumina (up to 1800°C), Graphite for specialized uses |

| Atmosphere Control | Inert, reactive gases, or vacuum; check vacuum system and seals |

| Temperature Control System | PID regulation, ±1°C accuracy, programmable multi-step recipes |

| Configuration | Single-zone for uniform heat, multi-zone for temperature gradients |

| Operational Costs | Energy efficiency, maintenance, and consumable lifespan |

| Safety Features | Over-temperature protection, door interlocks |

| Application Fit | Research (precision, gradients), production (throughput, efficiency), high-purity (material/vacuum purity) |

Ready to enhance your laboratory's capabilities with a tailored high-temperature tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering reliability, efficiency, and superior performance. Contact us today to discuss how we can support your specific needs and drive your research or production forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety