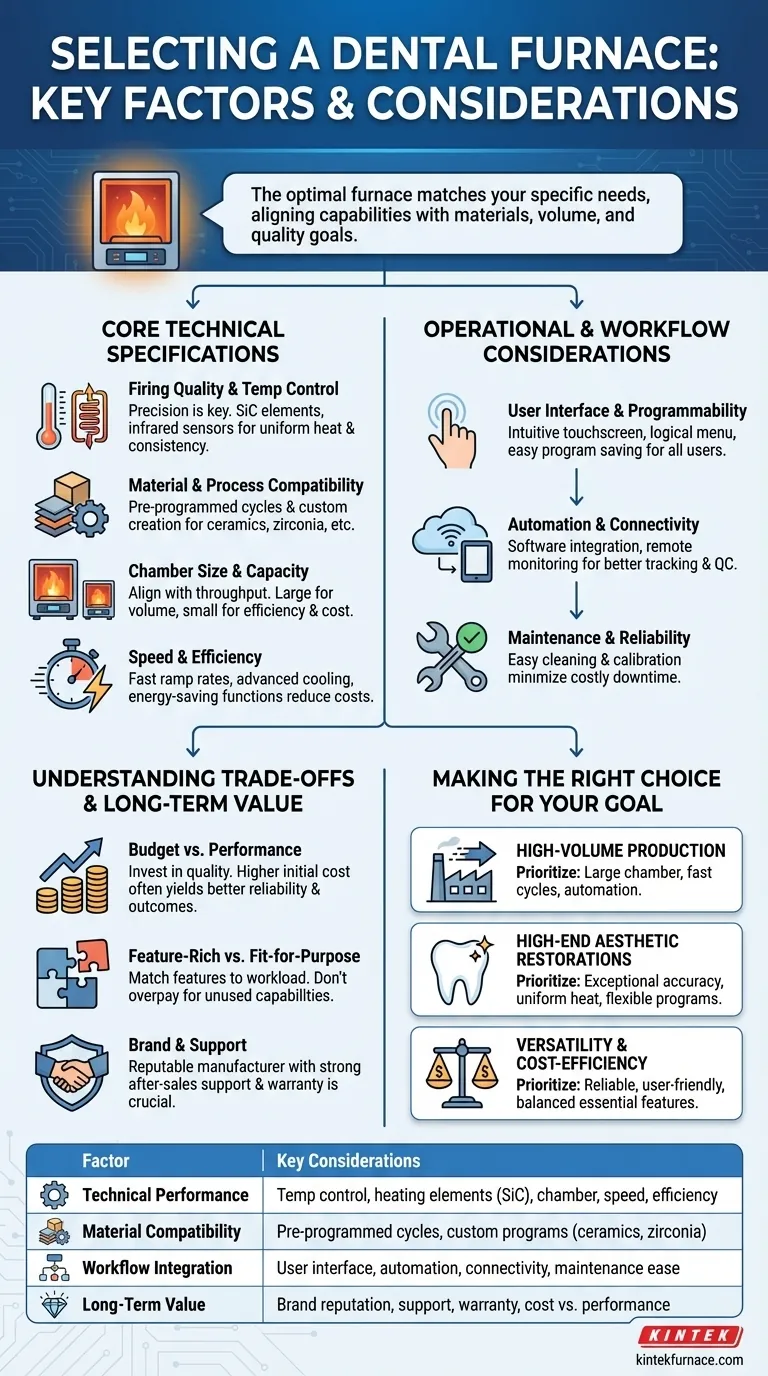

When selecting a dental furnace, the key factors are its technical performance, compatibility with your chosen materials, and its fit within your lab's specific workflow. Your decision should be guided by a clear understanding of your workload, the types of restorations you produce, and the long-term value of the investment, including brand reputation and after-sales support.

The optimal dental furnace is not the one with the most features, but the one that most precisely matches your specific needs. Choosing correctly is about aligning the furnace’s capabilities with your materials, production volume, and desired quality outcomes.

Core Technical Specifications

The technical capabilities of a furnace form the foundation of its performance. These specifications directly determine the quality, consistency, and durability of the final restorations.

Firing Quality and Temperature Control

The single most critical function of a furnace is its ability to execute a firing cycle with absolute precision. This requires uniform heat distribution throughout the chamber to prevent hotspots or cool zones that can compromise the restoration.

Look for furnaces with high-quality heating elements, such as silicon carbide (SiC), which offer durability and consistency. Precise temperature control, often enhanced by infrared sensors, ensures the furnace reaches and holds exact temperatures, which is vital for achieving the correct material properties and shade.

Material and Process Compatibility

A furnace must be compatible with the materials you use most, whether they are glass-ceramics, zirconia, or other advanced compounds. Each material has a unique firing protocol specified by its manufacturer.

A good furnace will feature pre-programmed cycles for common materials and also allow for easy creation of custom programs. This flexibility ensures you can adapt to new materials and achieve optimal results for every case.

Chamber Size and Capacity

The furnace's chamber size directly dictates your throughput. A larger chamber allows you to fire more restorations simultaneously, which is essential for a high-volume production lab.

However, a larger chamber is not always better. For an in-office or small boutique lab, a smaller, more efficient furnace may be a more practical and cost-effective choice, reducing energy consumption for smaller batches.

Speed and Efficiency

The time it takes to complete a firing cycle—including heat-up (ramp rate) and cool-down—has a significant impact on your lab's productivity. Faster cycles mean you can turn cases around more quickly.

Modern furnaces often include advanced cooling systems and energy-saving functions that can reduce operational costs by up to 40%. This efficiency translates directly to your bottom line over the lifetime of the equipment.

Operational and Workflow Considerations

Beyond the technical specifications, you must consider how the furnace will integrate into your daily operations and affect your team's efficiency.

User Interface and Programmability

A complex, non-intuitive interface can lead to user error, wasted time, and inconsistent results. Look for a furnace with a clear, user-friendly touchscreen and logical menu navigation.

The ability to easily create, save, and select firing programs is crucial for a streamlined workflow. This ensures any team member can operate the furnace reliably and with minimal training.

Automation and Connectivity

Advanced furnaces may offer features like software integration or remote monitoring. These capabilities allow for better tracking of cycles, easier quality control, and streamlined maintenance scheduling.

While not essential for every lab, these automation features can provide significant efficiency gains in a busy, digitally integrated environment.

Maintenance and Reliability

Downtime is extremely costly. A furnace that is difficult to clean or requires frequent service will disrupt your entire production schedule.

Evaluate the ease of routine maintenance, such as calibration and cleaning. A well-designed furnace minimizes these tasks, ensuring maximum uptime and consistent performance.

Understanding the Trade-offs and Long-Term Value

A furnace is a major capital investment. Making a purely cost-based decision without considering the hidden trade-offs can be a significant mistake.

Budget vs. Performance

The cheapest furnace is rarely the best value. Lower-cost models may lack the temperature precision or reliability needed for high-quality aesthetic work, leading to costly remakes and material waste.

View the purchase as an investment in quality and efficiency. A higher-priced furnace from a reputable brand often pays for itself through superior reliability, lower operational costs, and better clinical outcomes.

Feature-Rich vs. Fit-for-Purpose

It can be tempting to purchase a furnace with the most advanced features. However, if those features don't align with your actual needs, you are overpaying for capabilities you will never use.

Analyze your primary workload. If you specialize in monolithic zirconia, you don't need a furnace optimized for complex porcelain layering. Match the machine to your work.

The Importance of Brand and Support

A dental furnace is only as good as the company that stands behind it. A reputable manufacturer with a strong track record provides confidence in the equipment's quality and longevity.

Crucially, evaluate the after-sales support and warranty. When a technical issue arises, responsive and knowledgeable support is invaluable for getting your operations back online quickly.

Making the Right Choice for Your Goal

Ultimately, your selection should be a strategic decision based on the specific goals of your practice or laboratory.

- If your primary focus is high-volume production: Prioritize a furnace with a large chamber, fast cycle times, and robust automation features to maximize throughput.

- If your primary focus is high-end aesthetic restorations: Prioritize a furnace with exceptional temperature accuracy, uniform heat distribution, and flexible programming for precise material handling.

- If your primary focus is versatility and cost-efficiency: Prioritize a reliable, user-friendly furnace from a reputable brand that offers a good balance of essential features without unnecessary complexity.

Choosing the right furnace is an investment in the quality of your work and the efficiency of your business.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Technical Performance | Temperature control, heating elements (e.g., SiC), chamber size, ramp rate, energy efficiency |

| Material Compatibility | Pre-programmed cycles, custom program creation for materials like glass-ceramics and zirconia |

| Workflow Integration | User interface, automation, connectivity, maintenance ease |

| Long-Term Value | Brand reputation, after-sales support, warranty, cost vs. performance trade-offs |

Ready to enhance your dental lab's efficiency and quality? KINTEK specializes in providing advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to meet your unique experimental and production needs. Whether you focus on high-volume production, aesthetic restorations, or cost-efficiency, our solutions deliver precise temperature control, durability, and seamless workflow integration. Contact us today to discuss how we can support your goals with reliable, high-performance furnaces!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity