When selecting a tube furnace, the decision hinges on five core parameters: your required temperature range, the type of atmospheric control needed, the physical size of your samples, the level of temperature uniformity your process demands, and the furnace's physical orientation. Getting these right is critical, as they directly impact the reliability of your results and the safety of your lab.

Choosing a tube furnace is less about maximizing specifications and more about precisely matching the furnace's capabilities to your specific scientific or industrial process. A mismatch in temperature, atmosphere, or uniformity can compromise your results and lead to a costly investment error.

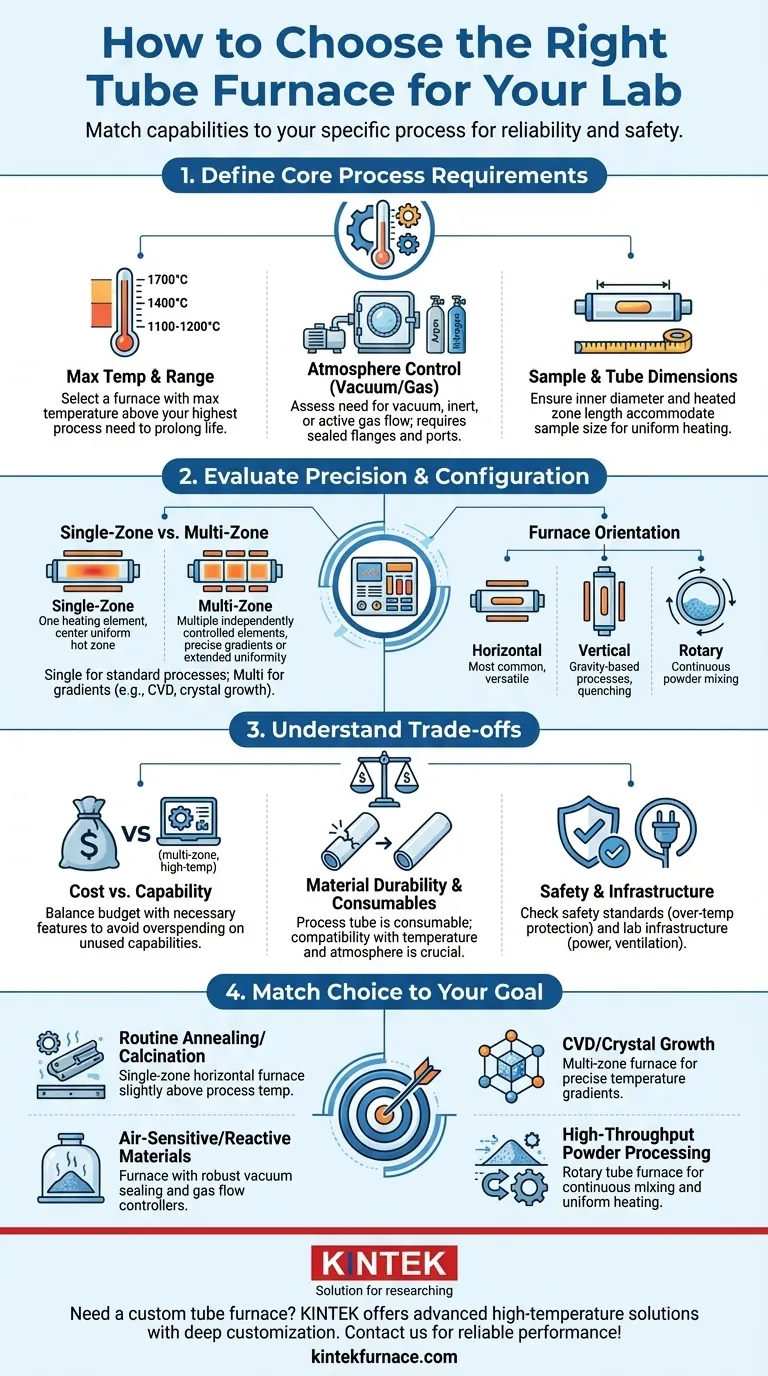

Define Your Core Process Requirements

Before evaluating specific models, you must first define the non-negotiable parameters of your work. These factors serve as your primary filter.

Maximum Temperature and Range

This is the most fundamental specification. Furnaces are typically categorized by their maximum operating temperature, often in tiers like 1100-1200°C, 1400°C, or up to 1700°C.

Always choose a furnace with a maximum temperature comfortably above your highest process temperature. Continuously operating a furnace at its absolute limit can shorten the life of its heating elements and insulation.

Atmosphere Control (Vacuum, Inert, or Active Gas)

Consider the environment your sample requires. Many applications can be done in ambient air, but many others require specific conditions.

A furnace's ability to hold a vacuum or manage a flow of controlled gas (such as inert argon or nitrogen, or a reducing gas) is a major design and cost factor. This requires sealed flanges, gas inlets/outlets, and compatible vacuum pumps or gas controllers.

Sample Size and Tube Dimensions

The furnace must accommodate your sample. The key dimensions are the tube diameter and the length of the heated zone.

Ensure the inner diameter of the furnace tube is large enough for your sample or sample holder, while the heated zone is long enough to ensure the entire sample resides within the area of uniform temperature.

Evaluate Precision and Furnace Configuration

Once you've filtered by your core needs, you can assess features that determine the quality, consistency, and type of thermal processing you can achieve.

Single-Zone vs. Multi-Zone Uniformity

A single-zone furnace has one set of heating elements and one controller. It is designed to create a single, uniform hot zone in the center of the tube and is sufficient for many standard heat treatment processes.

A multi-zone furnace (typically two or three zones) has multiple, independently controlled heating elements. This allows you to either extend the length of the uniform temperature zone or to create precise temperature gradients along the tube, which is essential for advanced applications like chemical vapor deposition (CVD) or crystal growth.

Furnace Orientation (Horizontal, Vertical, or Rotary)

The physical orientation of the furnace is dictated by your process.

Horizontal furnaces are the most common and versatile. Vertical furnaces are used for processes that benefit from gravity, such as sample quenching tests or specific material growth techniques. Rotary furnaces are designed for continuous processing and mixing of powders or granular materials.

Understanding the Trade-offs

A furnace is a significant investment, and it's crucial to understand the compromises between cost, performance, and long-term maintenance.

Cost vs. Capability

Higher temperatures, multi-zone control, and advanced atmosphere management capabilities all add significant cost. Be realistic about what you need versus what would be nice to have to avoid overspending on features you will not use.

Material Durability and Consumables

The furnace body and insulation are built for long-term use. However, the process tube itself (often made of quartz, alumina, or mullite) is a consumable item.

Its material must be compatible with your maximum temperature and chemical atmosphere. Aggressive processes can degrade tubes more quickly, adding to your operational costs.

Safety and Lab Infrastructure

Modern furnaces incorporate critical safety features like over-temperature protection and emergency shutdowns. Ensure any model you consider complies with relevant safety standards.

You must also consider your lab's infrastructure. High-temperature furnaces require significant electrical power, and processes using controlled atmospheres need proper ventilation and gas line management.

Making the Right Choice for Your Goal

Ultimately, the right furnace is the one that best fits your specific application. Use your primary goal as the deciding factor.

- If your primary focus is routine annealing or calcination in air: A single-zone horizontal furnace with a temperature rating slightly above your process need is the most cost-effective solution.

- If your primary focus is crystal growth or chemical vapor deposition (CVD): A multi-zone furnace is essential for creating the precise temperature gradients required for these sensitive processes.

- If your primary focus is working with air-sensitive or reactive materials: Prioritize a furnace with robust vacuum sealing and ports for mass flow controllers for precise atmosphere management.

- If your primary focus is high-throughput powder processing: A rotary tube furnace will provide the continuous material mixing and uniform heating necessary for consistent output.

By systematically aligning these factors with your specific application, you can select a tube furnace that serves as a reliable cornerstone of your laboratory's work.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range | Choose a furnace with max temperature above your process needs to avoid damage and ensure longevity. |

| Atmosphere Control | Assess requirements for vacuum, inert, or active gases; impacts sealing, gas inlets, and cost. |

| Sample Size | Ensure tube diameter and heated zone length accommodate your sample for uniform heating. |

| Temperature Uniformity | Decide between single-zone for standard processes or multi-zone for gradients in advanced applications. |

| Furnace Orientation | Select horizontal for versatility, vertical for gravity-based processes, or rotary for continuous powder mixing. |

Need a custom tube furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing precision, safety, and efficiency. Contact us today to discuss how we can support your specific application and deliver reliable performance!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide