Choosing the right Chemical Vapor Deposition (CVD) furnace requires a systematic evaluation of your specific process requirements. The most critical factors are the maximum processing temperature your chemistry demands, the ability to precisely control the gas atmosphere and vacuum level, and the physical size and material compatibility of the reaction chamber. These elements directly dictate the quality, reproducibility, and viability of your thin-film or material synthesis.

A CVD furnace is not just a high-temperature oven; it is a controlled chemical reactor. Your selection process should prioritize the factors that govern the chemical reaction itself—atmosphere, temperature, and material compatibility—over secondary features to ensure successful and repeatable outcomes.

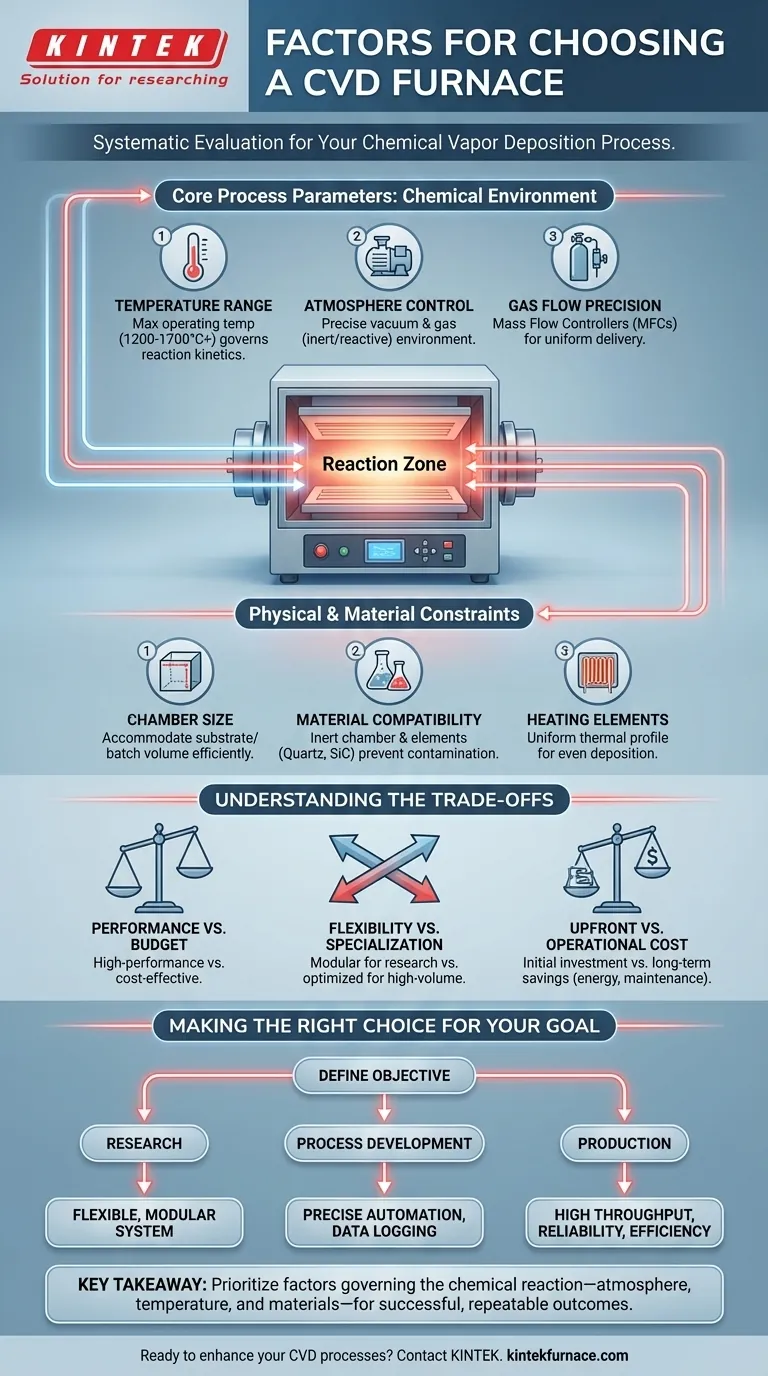

Core Process Parameters: The Chemical Environment

The heart of CVD is a chemical reaction. Your furnace's primary job is to create the perfect environment for that reaction to occur predictably and repeatedly.

Defining Your Temperature Range

The reaction kinetics of your CVD process are fundamentally governed by temperature. You must select a furnace that can comfortably reach and sustain your required processing temperature.

Laboratory setups often require temperatures up to 1200°C, while some industrial or advanced material processes can demand 1500°C, 1700°C, or higher. Always choose a furnace with a maximum operating temperature slightly above your highest process need to avoid running the equipment at its absolute limit.

Mastering Atmosphere and Vacuum Control

CVD processes are extremely sensitive to the atmospheric environment. Your choice of furnace must align with your need for vacuum, inert gas, or reactive gas environments.

Low-Pressure CVD (LPCVD) requires a robust vacuum system to remove contaminants and control precursor pressure. High-purity applications may necessitate high or ultra-high vacuum capabilities. The system must also manage the introduction of inert or reactive gases with precision.

Ensuring Gas Flow Precision

The quality and uniformity of your deposited film depend on the controlled delivery of precursor gases. A reliable CVD furnace includes precise mass flow controllers (MFCs).

These controllers allow you to set and maintain exact flow rates for multiple gases, ensuring the chemical stoichiometry of the reaction remains constant throughout the deposition process.

Physical and Material Constraints

Beyond the chemical environment, the physical characteristics of the furnace dictate its suitability for your application and its long-term reliability.

Sizing the Chamber for Your Substrate

The furnace's chamber size must accommodate your largest substrate or the desired batch volume for production.

A chamber that is too small is an obvious limitation, but a chamber that is excessively large for your typical sample size can lead to wasted energy and inefficient use of precursor gases.

Material Compatibility and Contamination

The materials used to construct the reaction chamber (or tube) and heating elements are critical. The chamber material, often quartz or alumina, must be chemically inert to your precursors and byproducts at high temperatures to prevent contamination.

Similarly, heating elements, such as Kanthal or silicon carbide (SiC), must be chosen for their durability and lack of reactivity with your process environment.

The Role of Heating Elements and Uniformity

Achieving a uniform film thickness across your entire substrate is only possible with uniform heating. The furnace's design and the quality of its heating elements determine the temperature uniformity across the chamber's "hot zone."

Look for systems specifically designed to provide a stable and consistent thermal profile for even deposition.

Understanding the Trade-offs

Every equipment decision involves balancing competing priorities. Being aware of these trade-offs is key to making an informed choice.

Performance vs. Budget

High-performance features like ultra-high vacuum, advanced automation, and extremely high-temperature capabilities come at a significant cost.

For exploratory research, a more budget-friendly, cost-effective system might be sufficient. For production, the investment in high-end features is often justified by improved yield and reliability.

Flexibility vs. Specialization

Laboratory furnaces are often designed to be modular and compact, offering the flexibility to run a wide range of experiments.

In contrast, industrial systems are typically specialized and optimized for a single, high-volume process. They trade flexibility for throughput and efficiency.

Upfront Cost vs. Operational Cost

Consider the long-term cost of ownership. A furnace with higher energy efficiency and lower maintenance requirements may have a higher initial price but can result in significant savings over its lifespan.

Always factor in the cost of consumables, power consumption, and routine maintenance when comparing options.

Making the Right Choice for Your Goal

Base your final decision on the primary objective of your work.

- If your primary focus is fundamental research: Prioritize a modular and flexible system with a wide operational window to accommodate diverse experiments.

- If your primary focus is process development: Emphasize precise automation, data logging, and control systems to ensure process repeatability and scalability.

- If your primary focus is pilot or full-scale production: Concentrate on chamber capacity, throughput, reliability, and low operational costs.

A thorough evaluation of these factors will ensure your chosen furnace becomes a reliable enabler of your work, not a source of limitations.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range | Maximum processing temperature (e.g., 1200°C to 1700°C+) for reaction kinetics |

| Atmosphere Control | Vacuum levels, inert/reactive gas handling, and mass flow controllers for precision |

| Chamber Size | Accommodates substrate/batch size to optimize energy and gas usage |

| Material Compatibility | Inert materials like quartz or alumina to prevent contamination |

| Heating Elements | Uniform thermal profile for even deposition (e.g., Kanthal, SiC) |

| Cost and Flexibility | Balance performance vs. budget, flexibility vs. specialization, and upfront vs. operational costs |

Ready to enhance your CVD processes with tailored furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can optimize your thin-film synthesis and boost efficiency!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics