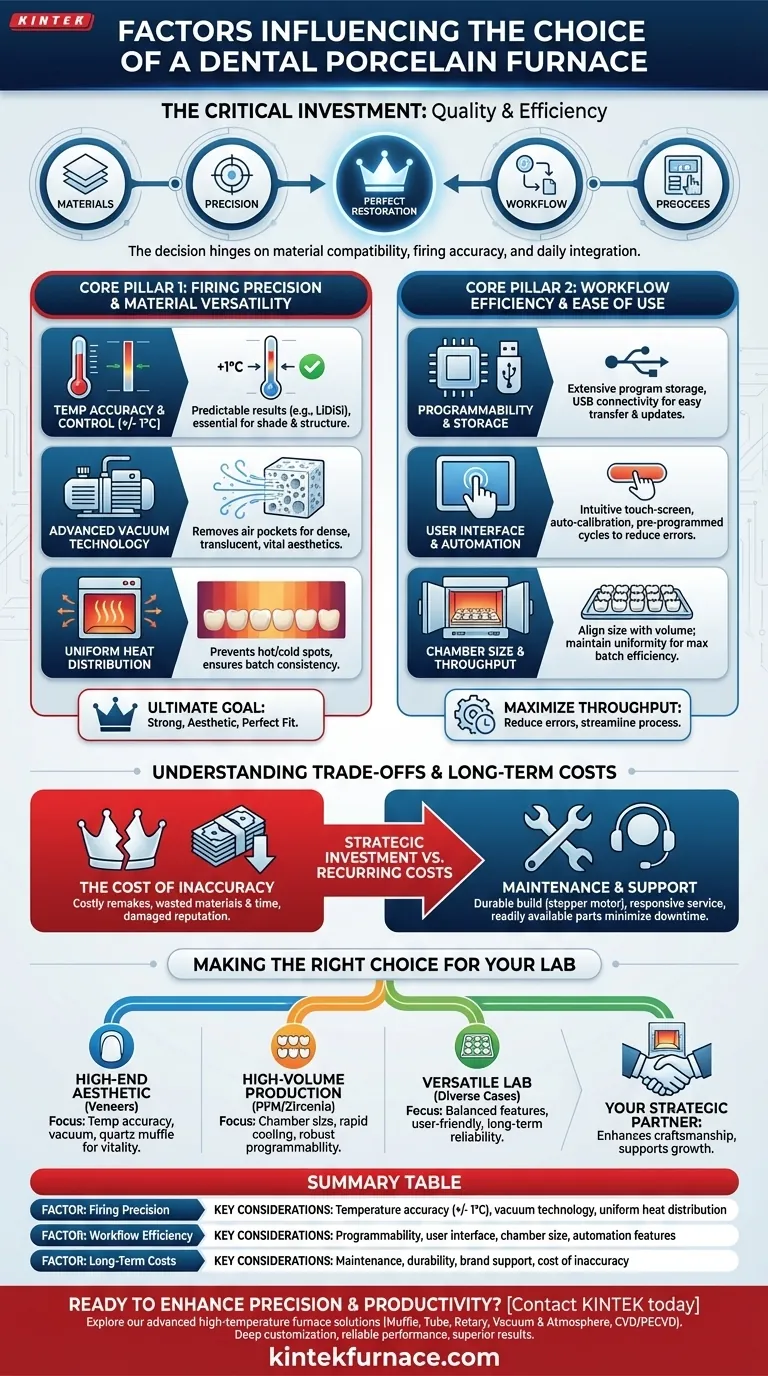

Choosing a dental porcelain furnace is a critical investment that directly impacts the quality of your restorations and the efficiency of your lab. The decision hinges on three primary factors: the specific ceramic materials you use, the required precision of the firing process, and how the furnace integrates into your daily workflow. A furnace must be compatible with your materials, consistently accurate in its temperature and atmosphere control, and efficient to operate.

The most effective approach is not to seek the furnace with the longest feature list, but to identify the technology that most reliably and efficiently produces the specific restorations your lab fabricates. This choice is a strategic decision about quality control, productivity, and long-term reliability.

Core Pillar 1: Firing Precision and Material Versatility

The ultimate goal of a furnace is to transform a shaped ceramic into a strong, aesthetic, and perfectly fitting restoration. This requires absolute control over the firing environment.

Temperature Accuracy and Control

Modern dental ceramics have narrow firing windows. A deviation of even a few degrees can compromise the shade, translucency, or structural integrity of the restoration.

Look for furnaces that guarantee accuracy within +/- 1°C. This level of precision is not a luxury; it is essential for achieving predictable results with materials like lithium disilicate and advanced layered porcelains.

Advanced Vacuum Technology

A strong, properly timed vacuum is critical for removing microscopic air pockets from the porcelain as it sinters. This process is what creates dense, translucent, and vital-looking restorations.

Inadequate vacuum systems can lead to porosity, which appears as cloudiness or grayness in the final crown and weakens the material. The furnace's ability to pull and maintain a deep vacuum is directly linked to final aesthetics.

Uniform Heat Distribution

The furnace chamber must provide uniform heat to every restoration, regardless of its position on the firing tray. An advanced chamber design with a quality quartz muffle prevents "hot spots" and "cold spots."

This ensures that a full batch of crowns fires just as consistently as a single unit, which is fundamental for predictable outcomes and lab productivity.

Core Pillar 2: Workflow Efficiency and Ease of Use

A precise furnace is useless if it is difficult or slow to operate. Efficiency features reduce the chance of human error and maximize your lab's throughput.

Programmability and Program Storage

Your lab likely works with multiple ceramic systems, each with unique firing parameters. A furnace must have extensive program storage and allow for easy creation of custom cycles.

Features like USB connectivity for program transfer and backup are significant quality-of-life improvements, ensuring consistency across multiple furnaces or allowing for easy updates as new materials are released.

User Interface and Automation

An intuitive, touch-screen interface dramatically reduces the learning curve and minimizes the risk of programming errors.

Look for automated features such as automatic temperature calibration, pre-programmed drying and cooling cycles, and an optical status display. These functions streamline the process, allowing technicians to focus on other critical tasks.

Chamber Size and Throughput

The size of the firing chamber should align with your lab's production volume. A larger chamber can increase throughput, but only if the furnace's heating element can maintain uniform temperature across the entire space.

Consider your typical batch size for crowns, bridges, and veneers when evaluating the usable space on the firing tray.

Understanding the Trade-offs and Long-Term Costs

The initial purchase price is only one part of the total cost of ownership. Inaccuracy and unreliability carry significant hidden expenses.

The Cost of Inaccuracy

An inconsistent furnace leads directly to costly remakes. This wastes not only expensive ceramic materials but also valuable technician time and can damage your lab's reputation for quality and punctuality. Investing in precision upfront is insurance against these recurring costs.

Maintenance and Durability

Consider the build quality of the furnace. A precision stepper motor for the lift operates quietly and smoothly, reducing wear and tear over time. Some modern furnaces also feature self-diagnostics or automated cleaning cycles that help maintain performance and extend the life of the heating element (muffle).

Brand Reputation and Support

When a furnace goes down, production stops. A manufacturer's reputation for reliability and, more importantly, responsive technical support is a critical factor. Ensure that service and replacement parts are readily available to minimize potential downtime.

Making the Right Choice for Your Lab

Evaluate furnace options based on the primary demands of your laboratory's work.

- If your primary focus is high-end aesthetic restorations (e.g., anterior veneers): Prioritize furnaces with exceptional temperature accuracy (+/- 1°C), advanced vacuum control, and a proven quartz muffle for superior vitality and translucency.

- If your primary focus is high-volume production (e.g., PFM or zirconia): Focus on chamber size, rapid and controlled cooling cycles, and robust programmability with ample storage to maximize throughput and consistency.

- If you are a versatile lab handling diverse cases: Seek a balanced furnace with a user-friendly interface, broad programmability for many material types, and a strong reputation for long-term reliability and support.

Ultimately, the right furnace is a strategic partner that enhances your craftsmanship and supports your lab's growth.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Firing Precision | Temperature accuracy (+/- 1°C), vacuum technology, uniform heat distribution |

| Workflow Efficiency | Programmability, user interface, chamber size, automation features |

| Long-Term Costs | Maintenance, durability, brand support, cost of inaccuracy |

Ready to enhance your lab's precision and productivity? Contact KINTEK today to explore our advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique dental restoration needs—ensuring reliable performance and superior results for your laboratory.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision