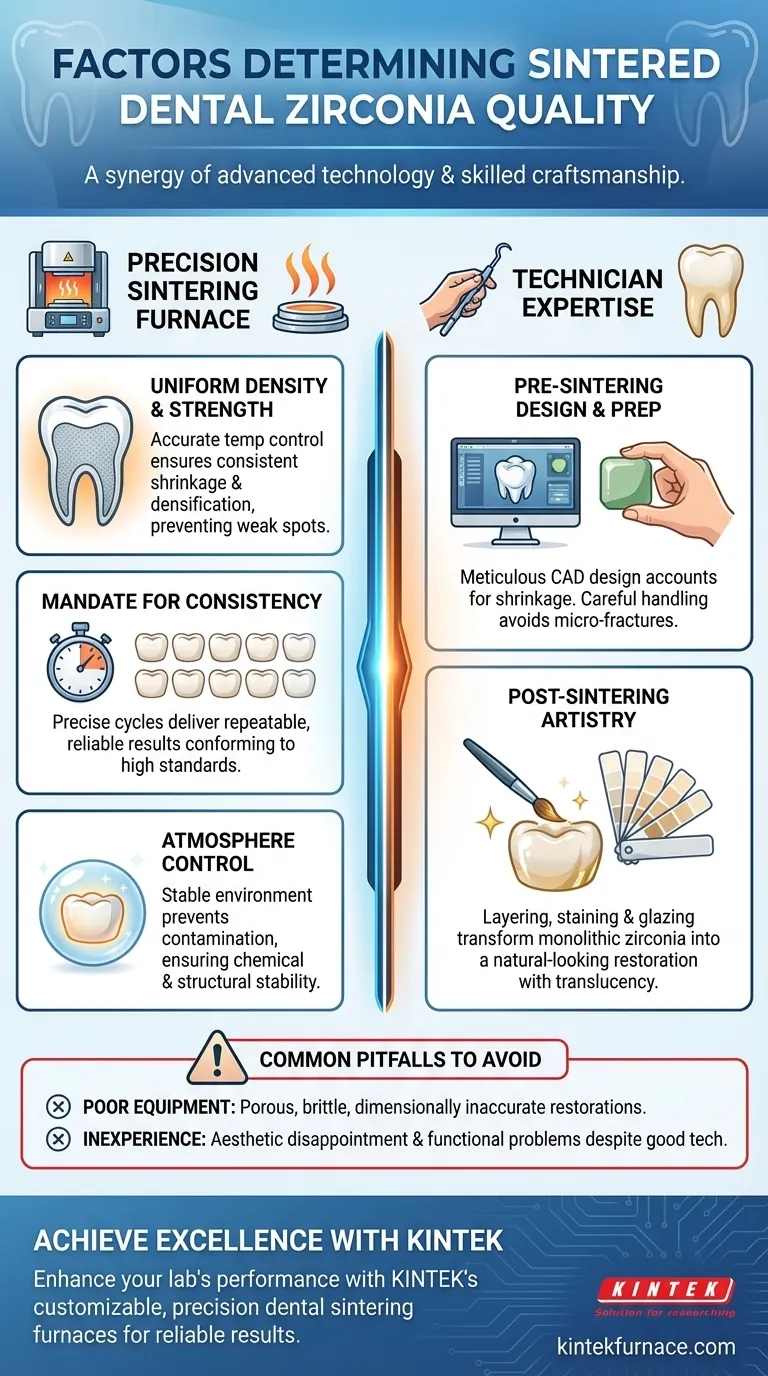

The quality of a sintered dental zirconia restoration is determined by two primary factors: the skill of the technician and the precision of the sintering furnace. While the zirconia material itself is important, it is the expert handling and the controlled firing process that transform the raw material into a durable and aesthetically pleasing final product.

The ultimate success of a zirconia restoration hinges less on the brand of zirconia and more on the mastery of the process. Inconsistent heat from a subpar furnace or inexpert handling by a technician are the most common points of failure, directly impacting the restoration's strength, fit, and lifespan.

The Critical Role of the Sintering Furnace

The sintering furnace is not just an oven; it is a precision instrument that governs the final properties of the zirconia. The quality of this equipment directly determines the quality of the restoration.

Achieving Uniform Density and Strength

A high-quality furnace provides exceptionally accurate and stable temperature control. This precision ensures the entire restoration heats and cools uniformly, a process critical for consistent shrinkage and densification.

This uniform sintering is what gives the final crown or bridge its optimal mechanical properties, preventing internal stresses or weak spots that could lead to premature failure.

The Mandate for Consistency

For any professional dental lab, consistent and repeatable results are non-negotiable. Modern sintering furnaces achieve this by locking in precise control over temperature cycles and sintering times.

This technological control ensures that a restoration made today will have the exact same properties as one made months from now, conforming to the highest standards every single time.

Atmosphere Control for Material Stability

Beyond just temperature, the furnace controls the atmosphere during the sintering cycle. This prevents contamination and ensures the chemical and structural stability of the zirconia.

This level of control is fundamental to producing a restoration that is not only strong but also biocompatible and color-stable for the long term.

The Irreplaceable Value of Technician Expertise

Technology alone cannot create a perfect restoration. The experience and artistry of the dental technician are equally crucial at every stage of the process.

Pre-Sintering Design and Preparation

Before the zirconia ever enters the furnace, a skilled technician meticulously designs the restoration using CAD software. They must account for the precise shrinkage that will occur during sintering.

Their handling of the fragile, pre-sintered "green state" zirconia is also critical to avoiding micro-fractures that could compromise the final product.

Post-Sintering Artistry and Finishing

After sintering, the zirconia is a strong but monolithic white structure. It is the technician's skill that turns it into a natural-looking tooth.

Using techniques like layering with porcelain or applying specialized stains and glazes, the technician imparts the translucency, color gradients, and character that make the restoration indistinguishable from a natural tooth.

Common Pitfalls to Avoid

Understanding the potential points of failure highlights why the combination of equipment and expertise is so vital.

The Cost of Inadequate Equipment

Using a low-quality furnace with poor temperature control is a direct path to failure. It can result in restorations that are porous, brittle, or dimensionally inaccurate.

This leads to poor marginal fits, increased chair time for adjustments, and a significantly shorter lifespan for the restoration.

The Risk of Inexperience

Even with the best furnace, an inexperienced technician can produce a poor result. Inaccurate digital design, improper placement in the furnace, or unskilled finishing can lead to functional problems and aesthetic disappointment.

The final outcome will lack the natural look required for high-quality cosmetic dentistry, regardless of the equipment used.

Making the Right Choice for Your Goal

Your approach to ensuring quality depends on your role in the dental restoration process.

- If your primary focus is practicing dentistry: Vet your dental lab partners by asking about the specific sintering furnaces they use and the experience level of their zirconia technicians.

- If your primary focus is operating a dental lab: Invest in high-precision sintering furnaces with documented temperature accuracy and prioritize the continuous training and education of your technical staff.

Ultimately, achieving excellence in zirconia restorations requires a deliberate synthesis of advanced technology and skilled, hands-on craftsmanship.

Summary Table:

| Key Factor | Why It Matters | Impact on Restoration |

|---|---|---|

| Sintering Furnace Quality | Ensures uniform temperature control and stable atmosphere. | Guarantees consistent density, strength, and dimensional accuracy. |

| Technician Expertise | Handles design, sintering setup, and post-sintering artistry. | Delivers precise fit, durability, and natural aesthetics. |

Achieve consistent, high-quality zirconia restorations with KINTEK’s precision sintering furnaces.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—including specialized dental sintering furnaces—all customizable for your lab’s unique needs. Ensure uniform heating, accurate shrinkage control, and reliable results for every crown and bridge.

Ready to enhance your lab’s performance? Contact our experts today to find the ideal sintering solution for your dental applications!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision