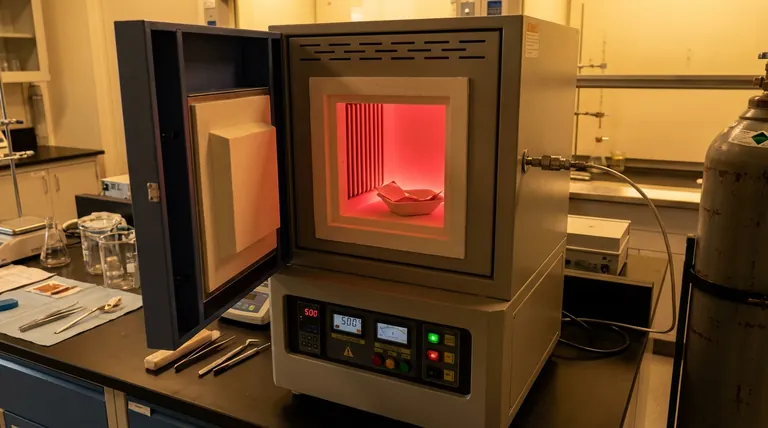

To evaluate the oxidation resistance of Single-Layer Graphene on copper (SLG/Cu), a high-temperature muffle furnace provides a strictly controlled environment featuring a pure oxygen atmosphere maintained at 500°C. The experimental protocol typically involves exposing the samples to these conditions for a duration of 60 seconds, designed to simulate extreme, accelerated oxidation.

The muffle furnace isolates the variables of temperature and atmospheric composition to create an accelerated stress test. This specific configuration allows researchers to pinpoint how physical characteristics, such as substrate surface roughness, directly influence the graphene layer's failure mechanisms.

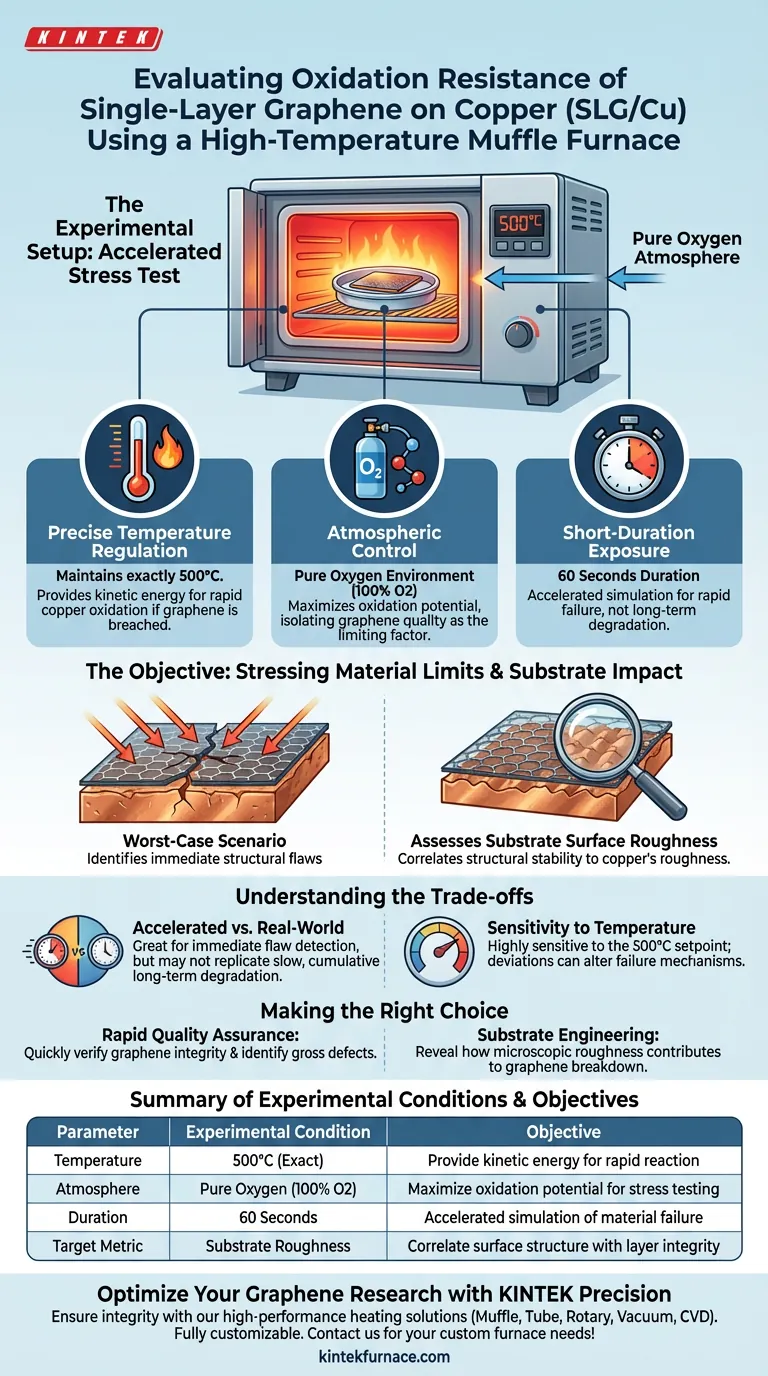

Defining the Experimental Parameters

Precise Temperature Regulation

The core of this experiment relies on maintaining a thermal environment of exactly 500°C.

At this temperature, the kinetic energy is sufficient to promote rapid chemical reactions between the copper substrate and oxygen, provided the protective graphene layer is breached.

Atmospheric Control

Unlike standard atmospheric testing, the muffle furnace utilizes a pure oxygen environment.

This maximizes the oxidation potential, ensuring that the limiting factor in the reaction is the protective quality of the graphene, rather than the availability of oxygen.

Short-Duration Exposure

The samples are subjected to this environment for a brief window of 60 seconds.

This short duration characterizes the test as an accelerated oxidation simulation, aiming to induce rapid failure rather than monitor long-term degradation.

The Objective of Accelerated Testing

Stressing the Material Limits

The combination of 500°C heat and pure oxygen creates a "worst-case" scenario for the material.

This helps identify weak points in the graphene coverage immediately, rather than waiting for slow corrosion processes to occur over days or weeks.

Evaluating Substrate Impact

A primary goal of this specific condition is to assess substrate surface roughness.

By observing where oxidation occurs under these intense conditions, researchers can correlate structural stability and anti-oxidation failure mechanisms directly to the roughness of the underlying copper.

Understanding the Trade-offs

Accelerated vs. Real-World Testing

This specific 60-second test at 500°C is an accelerated stress test, not a lifecycle simulation.

While it is excellent for identifying immediate structural flaws and roughness-induced failures, it may not perfectly replicate the slow, cumulative degradation a material faces under milder, long-term operating conditions.

Sensitivity to Temperature

The test is highly sensitive to the 500°C setpoint.

Deviations in temperature could either fail to trigger the necessary oxidation mechanisms or destroy the sample too quickly to observe the specific failure modes associated with surface roughness.

Making the Right Choice for Your Goal

To determine if this experimental setup aligns with your research objectives, consider your specific analytical focus.

- If your primary focus is rapid quality assurance: This setup allows you to quickly verify the integrity of the graphene layer and identify gross defects in under two minutes.

- If your primary focus is substrate engineering: This method provides the necessary aggression to reveal how microscopic surface roughness contributes to the breakdown of the protective graphene barrier.

This experimental condition effectively serves as a high-speed filter for determining the structural quality of SLG/Cu interfaces.

Summary Table:

| Parameter | Experimental Condition | Objective |

|---|---|---|

| Temperature | 500°C (Exact) | Provide kinetic energy for rapid reaction |

| Atmosphere | Pure Oxygen (100% $O_2$) | Maximize oxidation potential for stress testing |

| Duration | 60 Seconds | Accelerated simulation of material failure |

| Target Metric | Substrate Roughness | Correlate surface structure with layer integrity |

Optimize Your Graphene Research with KINTEK Precision

Ensure the integrity of your SLG/Cu interfaces with our high-performance heating solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique experimental parameters.

Whether you require precise 500°C oxygen environments or complex vapor deposition, our lab high-temperature furnaces provide the thermal stability and atmospheric control essential for advanced materials science.

Ready to elevate your lab's capabilities? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Songsong Yao, Tongxiang Fan. Effect of Copper Surface Roughness on the High-Temperature Structural Stability of Single-Layer-Graphene. DOI: 10.3390/ma17071648

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of a high-temperature muffle furnace for rare earth oxalate calcination? Achieve High-Purity REOs

- What role does a high-temperature box furnace play in FTO thin film PDA? Optimize Your Optoelectronic Performance

- What role does a muffle furnace play in eggshell pretreatment? Optimize CaO Production with Precise Calcination

- What role does a muffle furnace play in the solid-state reaction synthesis of Dy4T1-xGa12? Achieve Pure Alloy Phases

- How should the thermometer indicator be adjusted before using a muffle furnace? Ensure Accurate Temperature Readings

- What types of processes can modern muffle furnaces support? Discover Versatile High-Temperature Solutions

- What role does a muffle furnace play in g-C3N4 calcination? Master Precision Thermal Polycondensation

- What temperature ranges can muffle furnaces achieve? Find the Perfect Heat for Your Lab Needs