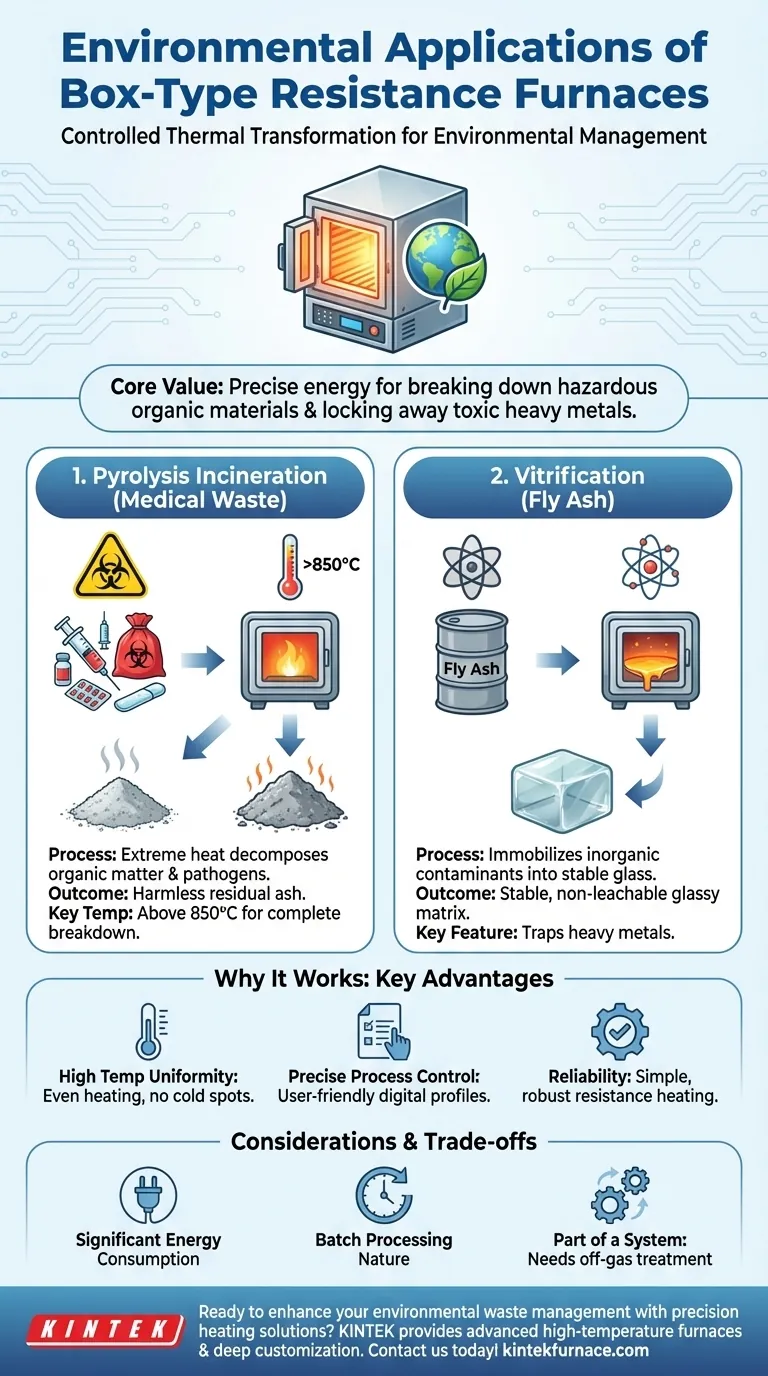

In environmental management, a box-type resistance furnace is a specialized tool used for two primary high-temperature applications: the thermal destruction of hazardous medical waste and the stabilization of toxic fly ash. These processes leverage the furnace's ability to achieve precise and uniformly high temperatures, which are essential for breaking down harmful compounds and immobilizing inorganic contaminants.

The core value of a box-type furnace in environmental work is not just heating, but controlled thermal transformation. It provides the precise energy required to break down hazardous organic materials and lock away toxic heavy metals in a stable, non-leachable glassy form.

The Principle: High-Temperature Waste Transformation

The fundamental purpose of using a box furnace for environmental tasks is to subject waste materials to extreme, controlled heat. This heat initiates chemical and physical changes that render the waste non-hazardous.

Pyrolysis Incineration of Medical Waste

This process uses extreme heat to decompose medical waste, which can include pathogens, pharmaceuticals, and plastics. The goal is complete destruction of hazardous organic matter.

A critical temperature threshold for this application is above 850°C. Operating at this level ensures the thermal breakdown of even the most stable organic pollutants and pathogens, resulting in a harmless residual ash.

Vitrification of Fly Ash

Vitrification is a process that immobilizes hazardous inorganic materials, particularly heavy metals found in fly ash from incinerators. It essentially turns the waste into a stable glass.

The furnace melts the ash, often with glass-forming additives, into a molten liquid. Upon cooling, this liquid hardens into a stable, glassy matrix that traps the heavy metal atoms within its structure, preventing them from leaching into soil or groundwater.

Why a Box Furnace is Suited for These Tasks

While many devices can produce heat, the specific design of a box-type resistance furnace offers key advantages for the precise demands of waste treatment.

High Temperature Uniformity

These furnaces are engineered to provide exceptionally even heating throughout their chamber. This uniformity is crucial for ensuring that the entire batch of waste material reaches the target temperature, leaving no "cold spots" where hazardous compounds could survive.

Precise Process Control

Modern furnaces offer user-friendly digital controls for setting and maintaining specific temperature profiles. This precision is vital for processes like pyrolysis, which can require stepped heating or extended holding times to achieve complete decomposition.

Structural Simplicity and Reliability

The design, which uses resistance wires to generate heat via radiation or convection, is simple and robust. This leads to high reliability and straightforward operation, which are valuable attributes when handling demanding environmental cleanup tasks.

Understanding the Trade-offs and Limitations

While powerful, these furnaces are not a universal solution. Understanding their limitations is key to using them effectively.

Significant Energy Consumption

Achieving temperatures of 850°C and higher is an energy-intensive process. While modern designs use efficient insulation to reduce heat loss, the operational cost in terms of electricity consumption is a primary consideration.

Batch Processing Nature

A box furnace operates on a batch-by-batch basis. You load the material, run the heating cycle, and then unload it. This makes it ideal for laboratory research, pilot projects, or treating moderate quantities of waste, but less suitable for the continuous, high-volume flow of a large municipal facility.

It's One Component in a System

The furnace itself only handles the thermal treatment. A complete waste processing system also requires components for material handling, loading, and, most importantly, off-gas treatment. The fumes produced during incineration or vitrification must be captured and scrubbed before being released into the atmosphere.

How to Apply This to Your Goal

Your choice of application depends entirely on the nature of the waste you need to treat.

- If your primary focus is destroying biological and organic contaminants: Pyrolysis incineration at temperatures above 850°C is the key application for ensuring complete and safe decomposition.

- If your primary focus is immobilizing toxic heavy metals from ash or soil: Vitrification is the ideal process, using the furnace to melt the waste into a stable, non-leachable glass.

- If you are conducting research and development: The furnace's precise control makes it an excellent tool for testing and optimizing the thermal treatment parameters for new or unique waste streams.

Ultimately, a box-type resistance furnace is a powerful and precise tool for transforming hazardous materials into inert forms through the controlled application of thermal energy.

Summary Table:

| Application | Key Process | Temperature Range | Outcome |

|---|---|---|---|

| Pyrolysis Incineration | Thermal decomposition of medical waste | Above 850°C | Destruction of pathogens and organic pollutants |

| Vitrification | Melting and solidification of fly ash | High temperatures (varies) | Stable, non-leachable glass matrix |

| Key Advantages | High temperature uniformity, precise control, reliability | Ideal for labs and pilot projects |

Ready to enhance your environmental waste management with precision heating solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories and environmental applications. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our furnaces can help you achieve safe and efficient thermal transformation of hazardous materials!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety