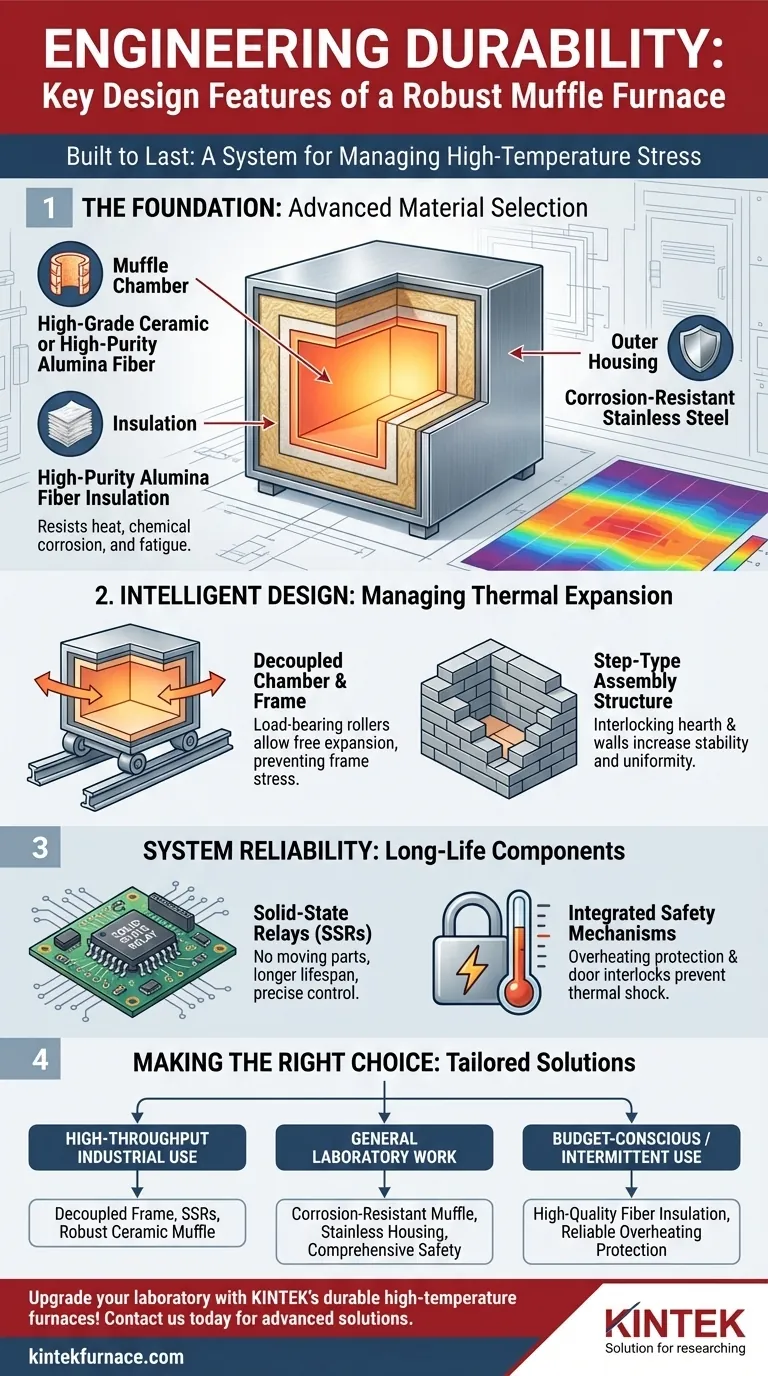

Ultimately, the durability of a muffle furnace is determined by a combination of robust material selection, intelligent structural design that manages thermal expansion, and reliable operational systems. The most durable furnaces use high-grade ceramic or alumina muffles, corrosion-resistant stainless steel housings, and feature designs that physically separate the furnace chamber from its frame to prevent stress-induced damage during heating and cooling cycles.

A truly durable furnace is not just built from strong materials; it is engineered as a system. Its longevity comes from how the design actively manages the immense physical stresses of high-temperature cycling, ensuring components can expand and contract without compromising structural integrity.

The Foundation of Durability: Material and Construction

The long-term reliability of a muffle furnace begins with the fundamental materials used in its construction. Each component is chosen to withstand specific stresses, from extreme heat to chemical corrosion.

The Muffle Chamber: The Heart of the Furnace

The muffle is the insulated inner chamber that isolates the sample from the heating elements. Its material composition is critical.

High-quality furnaces use muffles made from heat-resistant ceramics or high-purity alumina fiber. These materials offer excellent thermal stability and resistance to aggressive gases and vapors that can be released during processes.

The Outer Housing: The First Line of Defense

The external body, or housing, protects the internal components from the ambient environment.

Look for a stainless steel housing. This provides superior durability and corrosion resistance compared to painted steel, ensuring the furnace's structural integrity over many years, especially in laboratory or industrial settings where chemical spills may occur.

Insulation: Protecting the Structure

Efficient insulation does more than just retain heat; it protects the outer frame from thermal stress.

High-purity alumina fiber insulation is a key feature. It provides exceptional energy efficiency by minimizing heat loss and, by keeping the outer body cool, reduces the expansion and contraction cycles that can fatigue metal components over time.

Intelligent Design for Thermal Stress Management

Even the best materials will fail if the furnace's structure cannot accommodate the physical reality of thermal expansion. The most durable designs incorporate features specifically meant to manage this stress.

Decoupled Chamber and Frame

This is one of the most important, yet often overlooked, design features for longevity. In superior designs, the furnace chamber and the outer frame are engineered as separate components.

The chamber is often placed on load-bearing rollers, allowing it to slide freely as it heats up and expands. This prevents the expanding chamber from pushing against the frame, which would otherwise lead to warping, cracking, and premature failure.

Step-Type Assembly Structure

The way the insulation bricks or fiberboards are assembled also impacts durability.

A step-type assembling structure creates an interlocking design for the hearth and chamber walls. This provides greater stability and helps prevent heat from dissipating through joints, ensuring a more uniform temperature and reducing localized thermal stress.

Ensuring Longevity Through System Reliability

Beyond the physical structure, the operational components play a vital role in a furnace's service life. Reliable electronics and safety systems prevent failures that can cause catastrophic damage.

Solid-State Relays

The heating elements are switched on and off by relays. The type of relay used is a key indicator of quality.

Solid-state relays (SSRs) are vastly superior to mechanical relays for furnace applications. Because SSRs have no moving parts, they offer a significantly longer lifespan, silent operation, and more precise temperature control, reducing the risk of overshoot and thermal shock to the chamber.

Integrated Safety Mechanisms

Safety features are also durability features. Preventing operational errors is critical to protecting the equipment.

Mechanisms like overheating protection and door safety interlocks are essential. An interlock that automatically cuts power to the heating elements when the door is opened prevents sudden thermal shock to the chamber and protects the elements from damage.

Understanding the Trade-offs

Choosing a furnace involves balancing performance with cost. Understanding the compromises is key to making an informed decision.

Material Grade vs. Initial Cost

A furnace with a high-purity alumina muffle and a decoupled frame will have a higher upfront cost. However, for applications involving high temperatures or corrosive materials, this investment pays off in a significantly longer service life and lower lifetime cost.

Feature Complexity vs. Potential Failure Points

Features like quartz observation windows and gas inlet/exhaust ports are necessary for certain processes. However, each port or window is a potential point of failure if not engineered correctly. Ensure these features are robustly designed and well-sealed to avoid compromising the chamber's integrity.

Making the Right Choice for Your Application

Select a furnace based on the engineering principles that best align with your primary operational demands.

- If your primary focus is high-throughput industrial use: Prioritize a furnace with a decoupled chamber and frame, solid-state relays, and a robust ceramic muffle to withstand constant, demanding thermal cycles.

- If your primary focus is general laboratory work with varied samples: Choose a model with a corrosion-resistant muffle, a stainless steel housing, and comprehensive safety interlocks to ensure reliability across diverse applications.

- If your primary focus is budget-conscious or intermittent use: At a minimum, ensure the furnace has high-quality fiber insulation and reliable overheating protection to provide a baseline of safety and efficiency.

By understanding how these design features contribute to managing heat and physical stress, you can select a furnace built for lasting performance.

Summary Table:

| Design Feature | Key Contribution to Durability |

|---|---|

| High-Grade Ceramic or Alumina Muffle | Resists heat and corrosion, ensuring sample isolation and longevity |

| Stainless Steel Housing | Provides corrosion resistance and structural integrity in harsh environments |

| Decoupled Chamber and Frame | Manages thermal expansion to prevent stress-induced damage |

| Solid-State Relays (SSRs) | Offers precise control and longer lifespan with no moving parts |

| Integrated Safety Mechanisms | Prevents operational errors and thermal shock, protecting components |

Upgrade your laboratory with KINTEK's durable high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met precisely. Contact us today to enhance your lab's efficiency and reliability with a furnace built to last!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites