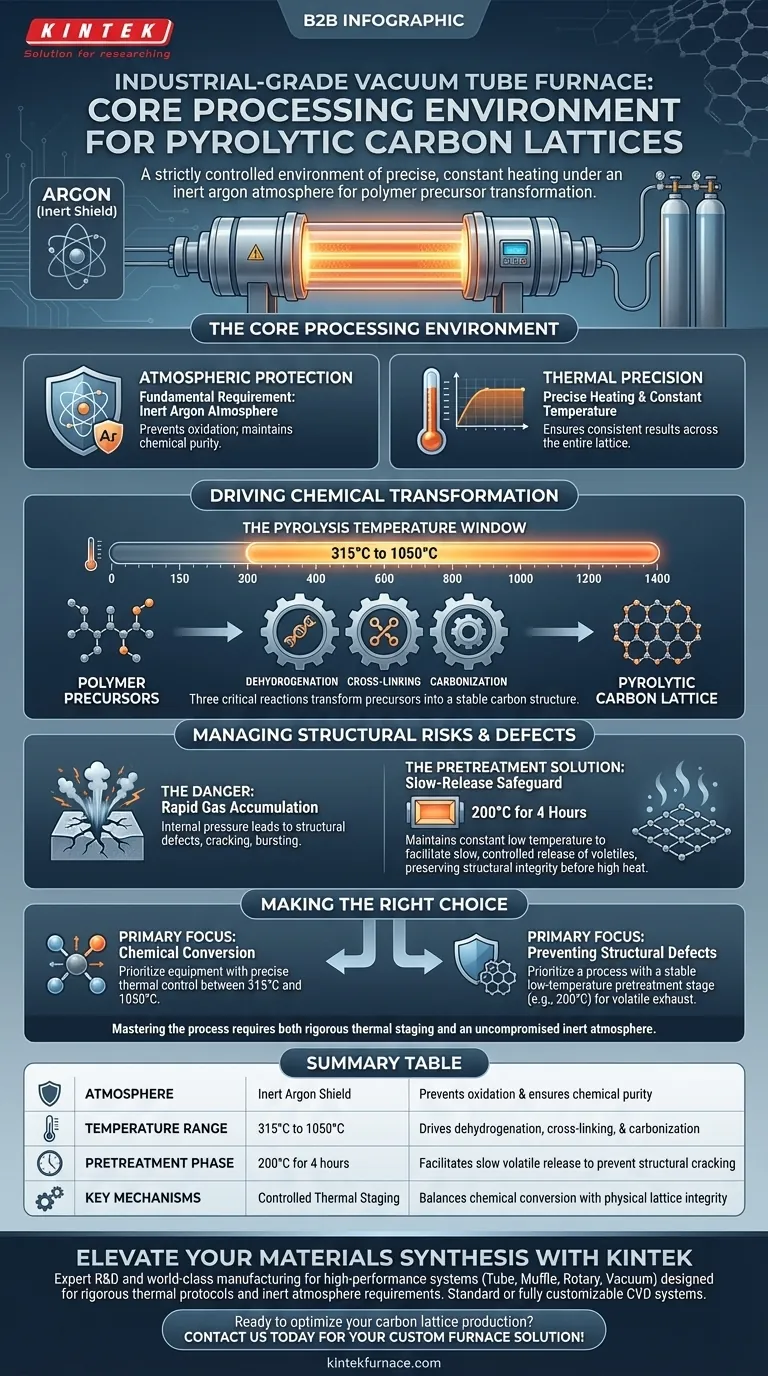

An industrial-grade vacuum tube furnace establishes a strictly controlled environment characterized by precise, constant heating under an inert argon atmosphere. This specialized setting is critical for the preparation of pyrolytic carbon lattices, ensuring that polymer precursors undergo the necessary chemical transformations without oxidation or external contamination.

The furnace creates a processing ecosystem that balances thermal precision with atmospheric protection. By maintaining an inert argon shield and executing specific temperature protocols, it drives essential molecular changes while preventing physical defects caused by volatile gas expansion.

The Components of the Processing Environment

Atmospheric Protection

The fundamental requirement for this process is an inert argon atmosphere.

This protective gas shield prevents oxygen from interacting with the materials during high-temperature processing, which is essential for maintaining chemical purity.

Thermal Precision

The furnace provides a precise heating and constant temperature environment.

Reliable thermal stability is required to ensure consistent results across the entire lattice structure during long processing cycles.

Driving Chemical Transformation

The Pyrolysis Temperature Window

To successfully prepare pyrolytic carbon lattices, the environment must support temperatures ranging from 315 °C to 1050 °C.

Controlling the heat within this specific window is the primary driver for converting the starting material into the final product.

Mechanisms of Change

Within this temperature range, the furnace facilitates three critical chemical reactions: dehydrogenation, cross-linking, and carbonization.

These mechanisms work in tandem to transform the polymer precursors into a stable carbon lattice structure.

Managing Structural Risks and Defects

The Danger of Rapid Gas Accumulation

A common pitfall in pyrolysis is the rapid accumulation of gases released during heating.

If these volatile substances are released too quickly, the internal pressure can lead to structural defects, cracking, or even the bursting of the material.

The Pretreatment Solution

To mitigate this risk, the processing environment must support a low-temperature pretreatment stage.

For example, maintaining a constant temperature of 200 °C for 4 hours facilitates the slow, controlled release of volatiles. This "slow-release" phase acts as a safeguard, preserving the structural integrity of the lattice before higher temperatures are applied.

Making the Right Choice for Your Goal

To optimize the preparation of pyrolytic carbon lattices, you must balance chemical conversion with physical stability.

- If your primary focus is chemical conversion: Ensure your equipment can maintain precise thermal control between 315 °C and 1050 °C to fully drive dehydrogenation and carbonization.

- If your primary focus is preventing structural defects: Prioritize a process that includes a stable low-temperature pretreatment (e.g., 200 °C) to exhaust volatiles before ramping up to pyrolysis temperatures.

Mastering this process requires a furnace that delivers both rigorous thermal staging and an uncompromised inert atmosphere.

Summary Table:

| Feature | Specification/Requirement | Purpose |

|---|---|---|

| Atmosphere | Inert Argon Shield | Prevents oxidation and ensures chemical purity |

| Temperature Range | 315°C to 1050°C | Drives dehydrogenation, cross-linking, and carbonization |

| Pretreatment Phase | 200°C for 4 hours | Facilitates slow volatile release to prevent structural cracking |

| Key Mechanisms | Controlled Thermal Staging | Balances chemical conversion with physical lattice integrity |

Elevate Your Materials Synthesis with KINTEK

Precision is non-negotiable when preparing complex pyrolytic carbon lattices. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, and Vacuum systems specifically designed to handle rigorous thermal protocols and inert atmosphere requirements. Whether you need standard lab high-temp furnaces or a fully customizable CVD system tailored to your unique research goals, our engineering team is ready to deliver the reliability you need.

Ready to optimize your carbon lattice production? Contact us today to discuss your custom furnace solution!

Visual Guide

References

- Ali Naderi, Yeqing Wang. Stiff, lightweight, and programmable architectured pyrolytic carbon lattices via modular assembling. DOI: 10.1038/s43246-025-00739-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing