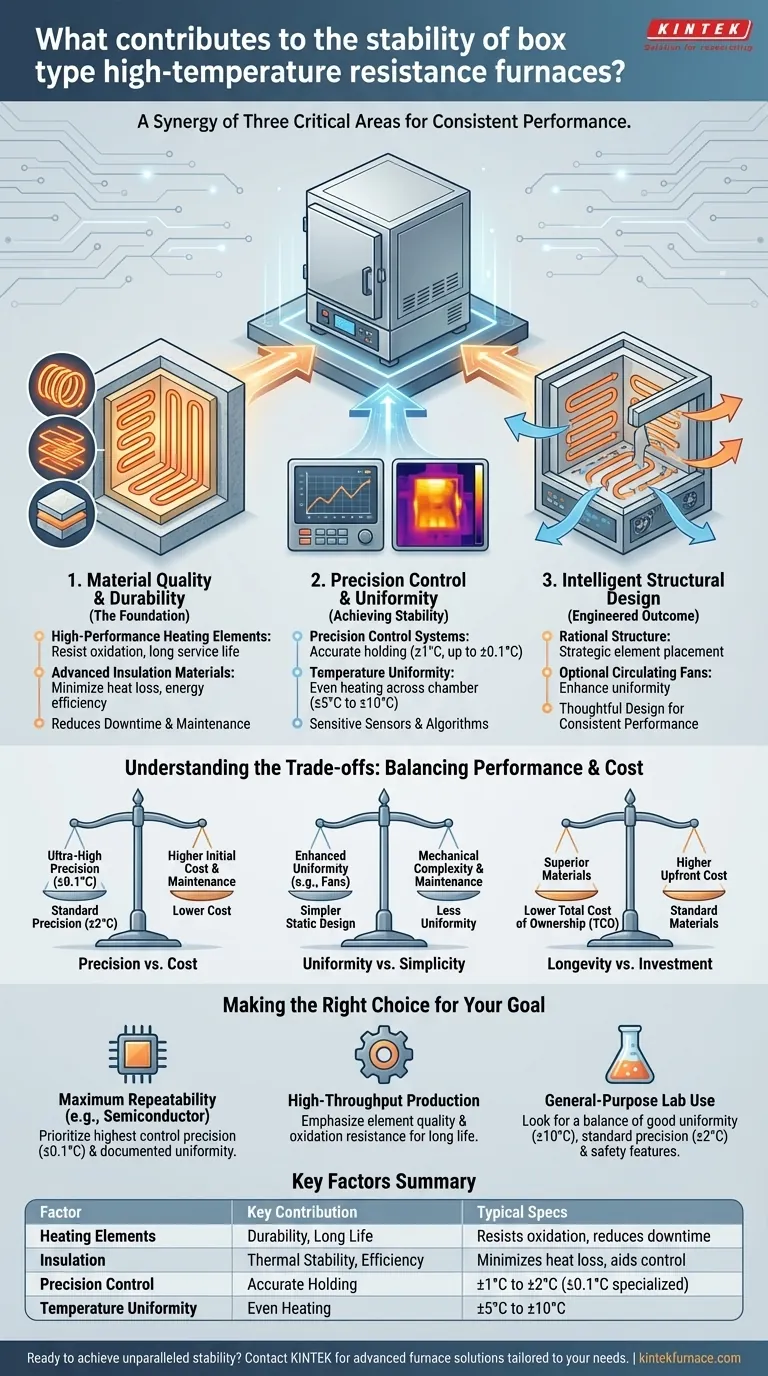

At its core, the stability of a box-type high-temperature resistance furnace is not the result of a single component, but a synergy between three critical areas: the durability of its core materials, the precision of its temperature control system, and the intelligence of its structural design. These elements work in concert to ensure consistent thermal performance, operational reliability, and a long service life.

True furnace stability is an engineered outcome. It emerges when high-quality materials, precise control systems, and thoughtful design converge to create an environment that is not only hot but also consistently and uniformly hot, cycle after cycle.

The Foundation: Material Quality and Durability

The long-term stability and reliability of any high-temperature furnace begin with the fundamental materials used in its construction. Poor quality here will undermine all other features.

High-Performance Heating Elements

The heating elements are the heart of the furnace. Elements made from high-quality alloys exhibit superior resistance to both extreme temperatures and oxidation.

This durability is what allows for continuous, long-term operation without degradation, directly translating to a longer service life and reduced production downtime.

Advanced Insulation Materials

Effective insulation is crucial for maintaining a stable internal environment. High-grade insulation materials minimize heat loss, which improves energy efficiency.

More importantly, by preventing thermal leakage, quality insulation helps the control system maintain a set temperature with less effort, contributing significantly to overall thermal stability.

Achieving Thermal Stability: Control and Uniformity

While materials provide the potential for stability, it is the control system and physical design that realize it. These two aspects determine how precisely and evenly heat is managed within the chamber.

Precision Temperature Control Systems

Modern furnaces are equipped with high-precision temperature control systems that rely on sensitive sensors and sophisticated algorithms.

These systems can typically achieve a control accuracy of ±1°C to ±2°C, ensuring the furnace holds the target temperature with minimal deviation. For highly sensitive processes like semiconductor annealing, specialized models can even reach an accuracy of ±0.1°C.

The Importance of Temperature Uniformity

Temperature uniformity refers to the consistency of temperature across the entire furnace chamber. It is distinct from control precision, which measures temperature at a single point.

Uniformity is achieved through rational furnace structure, strategic placement of heating elements, and sometimes the use of circulating fans. A well-designed furnace maintains temperature uniformity within ±5°C to ±10°C, guaranteeing that every part of the workpiece is heated evenly.

Understanding the Trade-offs: Precision vs. Cost

Achieving maximum stability involves balancing performance requirements with practical constraints. Not every application requires the highest possible specification in every category.

The Cost of Ultra-High Precision

Pursuing extreme temperature control accuracy (like ±0.1°C) requires more advanced sensors, controllers, and calibration. This significantly increases the initial cost and can add complexity to maintenance. For many heat-treating applications, a standard accuracy of ±2°C is more than sufficient.

Uniformity vs. Simplicity

Features that enhance uniformity, such as internal circulating fans, are highly effective but introduce mechanical complexity. A fan is a moving part that requires maintenance and can be a point of failure, a trade-off against the simpler, static design of a basic furnace.

Material Longevity vs. Initial Investment

Investing in superior heating elements and insulation materials demands a higher upfront cost. However, this investment typically results in a lower total cost of ownership by drastically reducing the frequency of maintenance, element replacement, and costly production downtime.

Making the Right Choice for Your Goal

Selecting the right furnace requires matching its stability features to your specific process needs.

- If your primary focus is maximum process repeatability (e.g., semiconductor or aerospace): Prioritize documented temperature uniformity and the highest possible control precision (±0.1°C).

- If your primary focus is high-throughput, continuous production: Emphasize the quality and oxidation resistance of the heating elements and insulation to ensure long service life.

- If your primary focus is general-purpose lab use with various tasks: Look for a balance of good uniformity (±10°C), standard precision (±2°C), and robust safety features like over-temperature alarms.

By understanding these contributing factors, you can select a furnace that is not just a piece of equipment, but a stable and reliable tool for achieving your goals.

Summary Table:

| Factor | Key Contribution | Typical Specs |

|---|---|---|

| High-Performance Heating Elements | Durability, long service life | Resists oxidation, reduces downtime |

| Advanced Insulation Materials | Thermal stability, energy efficiency | Minimizes heat loss, aids control |

| Precision Temperature Control | Accurate temperature holding | ±1°C to ±2°C (up to ±0.1°C for specialized models) |

| Temperature Uniformity | Even heating across chamber | ±5°C to ±10°C |

Ready to achieve unparalleled stability in your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're in semiconductor, aerospace, or general research, our furnaces ensure reliable thermal performance and long-term efficiency. Contact us today to discuss how we can support your specific goals and enhance your laboratory's capabilities!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- How does a laboratory high-temperature box furnace assist in evaluating concrete fire resistance? | KINTEK

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure