To achieve temperatures above 1200 °C, tube furnaces rely on specialized high-temperature heating elements and robust ceramic process tubes. The specific material used for the heating element directly determines the furnace's maximum achievable temperature, with silicon carbide (SiC) being used for temperatures up to 1500 °C and molybdenum disilicide (MoSi₂) required for temperatures reaching up to 1800 °C. These elements are paired with a process tube, typically made of high-purity alumina, capable of withstanding the extreme thermal stress.

The core challenge of high-temperature operation isn't just generating heat, but containing it reliably without component failure. The solution lies in a carefully matched system of advanced heating elements and durable ceramic tubes designed specifically for extreme thermal environments.

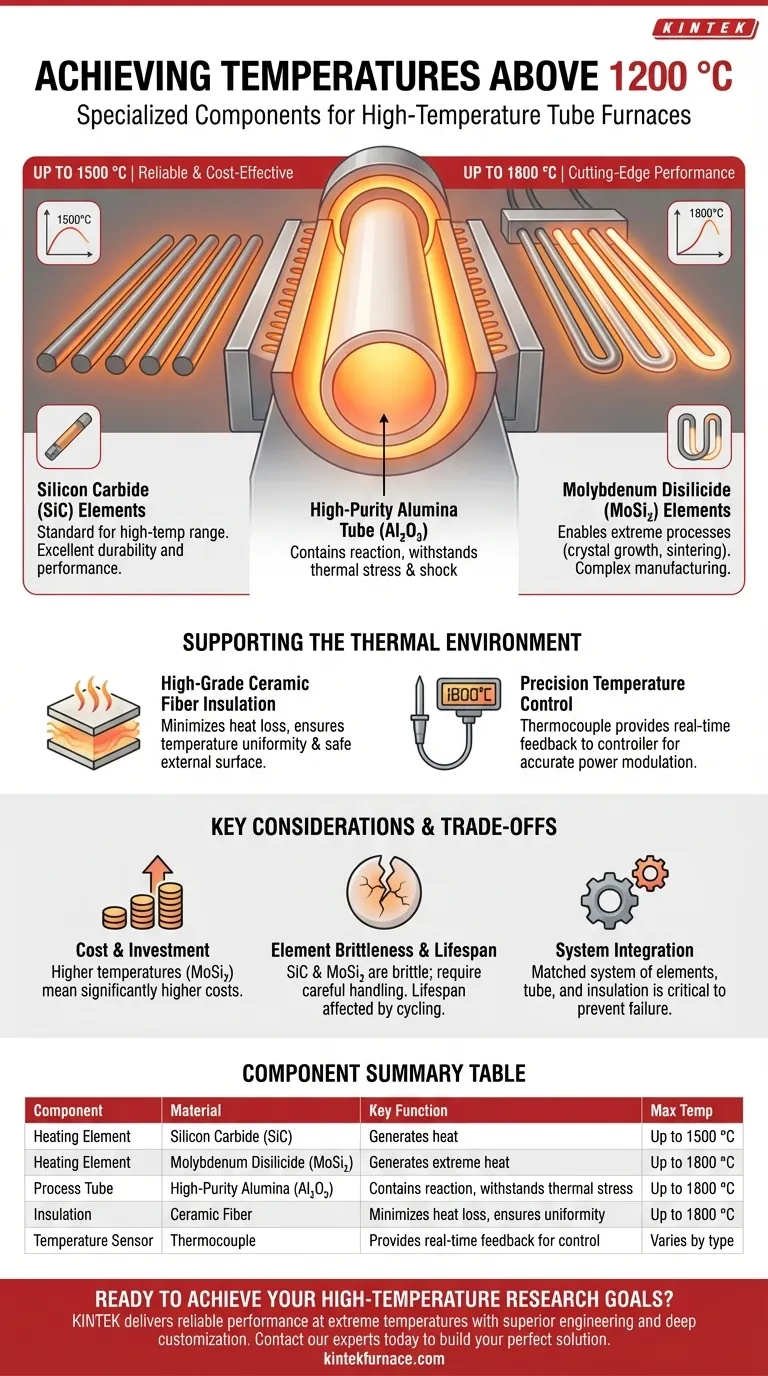

The Anatomy of a High-Temperature Tube Furnace

A standard tube furnace operating below 1200 °C often uses heating coils embedded in a ceramic fiber chamber. To exceed this threshold, the fundamental design must change to incorporate materials that remain stable at much higher temperatures.

The Critical Role of Heating Elements

The heating element is the heart of the furnace, converting electrical energy into thermal energy. The choice of material is the single most important factor defining the furnace's operational limits.

For Temperatures Up to 1500 °C: Silicon Carbide (SiC)

Silicon carbide (SiC) is the established material for furnaces in the 1200 °C to 1500 °C range. These elements are typically configured as rods suspended within the insulated chamber, positioned alongside the process tube to provide uniform heating. Their durability and performance make them a standard for many high-temperature applications.

For Temperatures Up to 1800 °C: Molybdenum Disilicide (MoSi₂)

To reach the highest operational temperatures of 1800 °C, furnaces must use molybdenum disilicide (MoSi₂) heating elements. These advanced components can operate at extreme temperatures where SiC would fail, enabling sophisticated processes like crystal growth, sintering of advanced ceramics, and specialized materials research.

The Process Tube: Containing the Reaction

The process tube is the vessel that contains the sample and the controlled atmosphere. It must maintain its structural integrity and chemical inertness under intense heat.

Alumina: The High-Temperature Standard

For most applications above 1200 °C, high-purity alumina (Al₂O₃) is the preferred tube material. Its excellent thermal shock resistance and high melting point make it reliable and stable.

Specialized Tube Materials

In processes involving highly corrosive materials, specialized tubes made from materials like tungsten or molybdenum may be required, even though alumina is generally robust. The choice of tube material must always be compatible with the sample and process chemistry.

Supporting Components

Beyond the core heating system, several other components are essential for stable, high-temperature operation.

High-Grade Insulation

The furnace chamber is lined with dense, high-purity ceramic fiber insulation. This material is critical for minimizing heat loss, ensuring temperature uniformity, and maintaining a safe external temperature.

Precision Temperature Control

Accurate temperature management is non-negotiable. This is achieved through a thermocouple, a sensor that provides real-time temperature feedback to a controller, which then modulates the power sent to the heating elements to maintain the desired setpoint.

Understanding the Trade-offs

Selecting a high-temperature furnace involves balancing performance with operational realities. Pushing to higher temperatures introduces new complexities and costs.

Higher Temperatures Mean Higher Costs

Furnaces equipped with MoSi₂ elements are significantly more expensive than their SiC counterparts. The raw materials and manufacturing processes for these advanced components are more complex, leading to a higher initial investment.

Element Lifespan and Brittleness

Both SiC and MoSi₂ elements are ceramic-based and therefore brittle at room temperature. They require careful handling during installation and maintenance. Their operational lifespan is also finite and can be affected by factors like thermal cycling and atmospheric conditions.

The Importance of System Integration

A furnace is more than just its heating elements. The tube, insulation, and control system must all be designed to work together seamlessly. Using a process tube not rated for the furnace's maximum temperature, for example, will inevitably lead to failure.

Making the Right Choice for Your Goal

Your specific temperature requirements are the primary driver for selecting the right furnace components.

- If your primary focus is on applications up to 1500 °C: A furnace with Silicon Carbide (SiC) heating elements and an alumina tube provides a reliable and cost-effective solution.

- If your primary focus is on cutting-edge research requiring up to 1800 °C: You must invest in a system built with Molybdenum Disilicide (MoSi₂) elements and compatible high-purity ceramics.

Ultimately, understanding the interplay between these specialized materials empowers you to select a furnace that can safely and reliably achieve your experimental goals.

Summary Table:

| Component | Material | Key Function | Max Temperature |

|---|---|---|---|

| Heating Element | Silicon Carbide (SiC) | Generates heat | Up to 1500 °C |

| Heating Element | Molybdenum Disilicide (MoSi₂) | Generates extreme heat | Up to 1800 °C |

| Process Tube | High-Purity Alumina | Contains reaction, withstands thermal stress | Up to 1800 °C |

| Insulation | Ceramic Fiber | Minimizes heat loss, ensures uniformity | Up to 1800 °C |

| Temperature Sensor | Thermocouple | Provides real-time feedback for control | Varies by type |

Ready to Achieve Your High-Temperature Research Goals?

KINTEK's advanced tube furnace solutions are engineered to deliver reliable performance at extreme temperatures. Whether your work requires the robust 1500°C capability of Silicon Carbide elements or the cutting-edge 1800°C performance of Molybdenum Disilicide systems, our expertise ensures you get the precise thermal environment your experiments demand.

Why choose KINTEK?

- Superior Engineering: Leveraging exceptional R&D and in-house manufacturing, we build furnaces with unmatched temperature uniformity and control.

- Deep Customization: We tailor our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems to your unique experimental requirements.

- Proven Reliability: Our high-purity alumina tubes and advanced insulation materials are designed for long-term stability in the most demanding conditions.

Let's build the perfect high-temperature solution for your lab. Contact our experts today to discuss your application and receive a personalized recommendation.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents