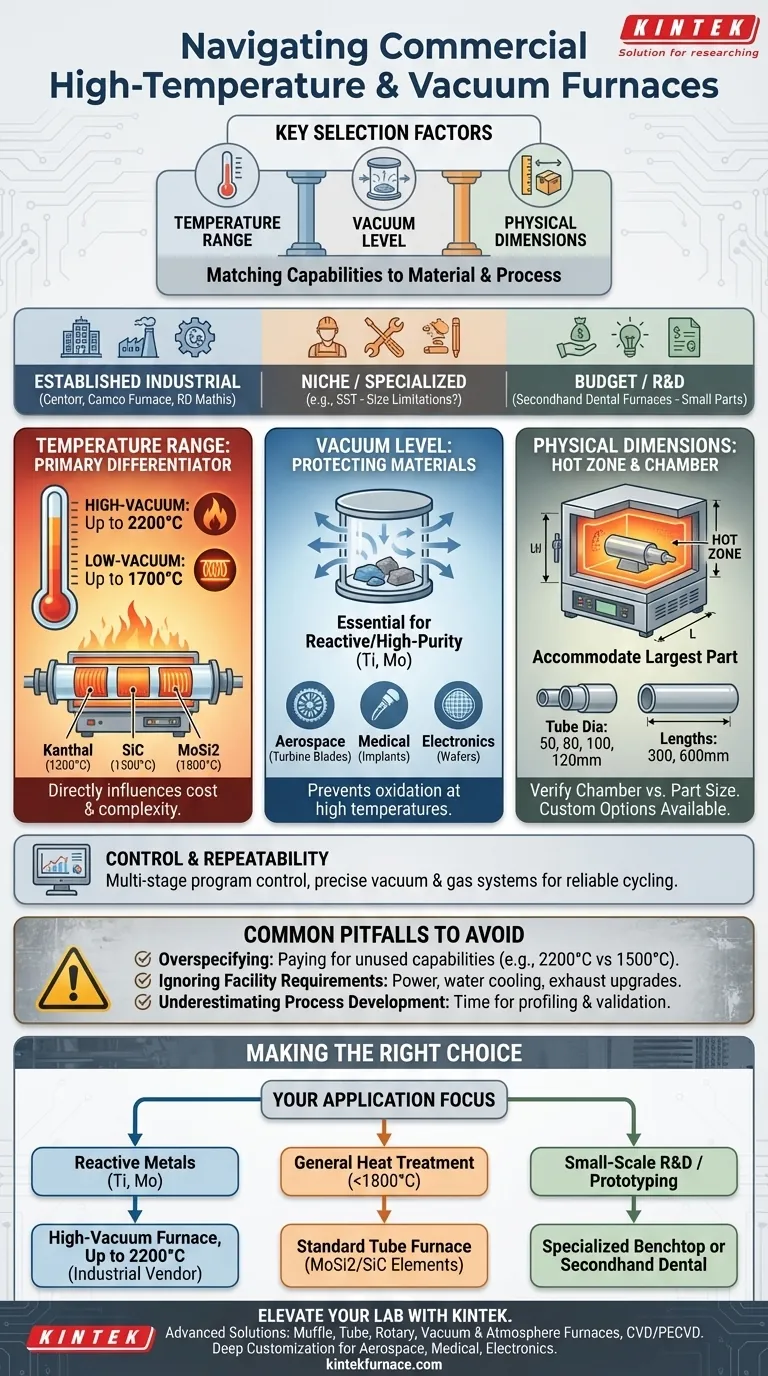

For commercial vacuum or high-temperature furnaces, several key vendors and options exist, including established industrial suppliers like Centorr, Camco Furnace, and RD Mathis. Other specialized options include SST furnaces, which may have size and temperature limitations, and even secondhand dental furnaces for processing very small parts on a budget.

Choosing the right high-temperature furnace is less about a specific brand name and more about matching the furnace's capabilities to your material and process requirements. The decision hinges on three core factors: the maximum temperature, the level of vacuum needed, and the physical size of the parts being processed.

Deconstructing Furnace Specifications

Before evaluating vendors, you must first define your technical needs. The "best" furnace is the one that meets your requirements without being unnecessarily complex or expensive.

Temperature Range: The Primary Differentiator

The maximum required temperature is the first and most important specification. It directly influences the furnace's cost, complexity, and construction.

A key distinction exists between furnace types. Low-vacuum atmosphere furnaces typically operate up to 1700°C.

For more demanding applications, high-vacuum furnaces can achieve temperatures up to 2200°C.

Common tube furnaces use different heating elements to reach specific temperature ranges, such as Kanthal (up to 1200°C), SiC (up to 1500°C), or MoSi2 (up to 1800°C).

Vacuum Level: Protecting Your Materials

The vacuum system is not just about removing air; it's about creating a controlled environment to protect sensitive materials during heating.

High-vacuum capabilities are essential when working with reactive or high-purity materials, such as titanium (Ti) and molybdenum (Mo), which would otherwise oxidize at high temperatures.

This capability is critical in industries like aerospace for creating turbine blades, medical for treating surgical implants, and electronics for producing semiconductor wafers.

Physical Dimensions: The Hot Zone and Chamber

You must ensure the furnace's "hot zone"—the internal area that reaches the target temperature—can accommodate your largest part.

Standard tube furnaces often come with tube diameters of 50, 80, 100, or 120mm and hot zone lengths of 300 or 600mm.

Be aware that some vendors, like SST, are noted as having potential size limitations. Always verify chamber dimensions against your specific needs. Most vendors offer custom dimensions.

Control and Repeatability

Modern furnaces are defined by their precision. Look for advanced control systems that ensure your process is repeatable and reliable.

Key features include multi-stage program temperature control, precise vacuum systems, and gas control systems. These allow for complex heating, soaking, and cooling cycles essential for advanced material processing.

Understanding the Commercial Landscape

With your technical requirements defined, you can now evaluate the different types of commercial offerings.

Established Industrial Vendors

Companies like Centorr, Camco Furnace, and RD Mathis are examples of vendors that supply robust, industrial-grade furnaces for a wide range of production and research applications.

Niche and Specialized Options

Some vendors may focus on a specific market segment. For example, SST furnaces are mentioned in a context that suggests they may be suited for smaller-scale or more specialized tasks where their size is not a limiting factor.

The Budget-Conscious Approach: Secondhand Equipment

For small parts, R&D, or proof-of-concept work, a secondhand dental furnace can be a viable, low-cost entry point. However, this approach comes with trade-offs regarding support, condition, and control capabilities.

Common Pitfalls to Avoid

Selecting a furnace involves significant capital investment. Avoiding common mistakes is critical for ensuring a positive return.

Overspecifying Temperature and Vacuum

A furnace capable of 2200°C and high vacuum is far more expensive than one rated for 1500°C in a low vacuum. Do not pay for capabilities you will never use. Match the specification tightly to your known process requirements.

Ignoring Facility Requirements

High-temperature furnaces are power-intensive and may require special electrical service, water cooling lines, and dedicated exhaust. Always factor these facility upgrades into your total project cost.

Underestimating Process Development

The furnace is a tool, not a complete solution. Significant time is often required to develop and validate the precise heating profiles, ramp rates, and vacuum cycles that yield the desired results for your specific material and part geometry.

Making the Right Choice for Your Application

Your final selection should be a direct result of your technical and operational goals.

- If your primary focus is processing reactive metals like titanium: You must prioritize a high-vacuum furnace capable of reaching up to 2200°C from an industrial vendor.

- If your primary focus is general heat treatment or sintering below 1800°C: A standard tube furnace with the appropriate MoSi2 or SiC heating elements is likely the most cost-effective and reliable solution.

- If your primary focus is small-scale R&D or prototyping non-reactive parts: Consider specialized benchtop models or evaluate secondhand dental furnaces to minimize initial investment.

Ultimately, a thorough definition of your material, process, and size requirements will guide you to the most effective and economical furnace solution.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range | Low-vacuum up to 1700°C, high-vacuum up to 2200°C, tube furnaces with Kanthal (1200°C), SiC (1500°C), MoSi2 (1800°C) |

| Vacuum Level | Essential for reactive materials (e.g., titanium, molybdenum); critical in aerospace, medical, electronics industries |

| Physical Dimensions | Hot zone sizes: tube diameters 50-120mm, lengths 300-600mm; verify against part size, custom options available |

| Control and Repeatability | Multi-stage program control, precise vacuum and gas systems for reliable heating cycles |

| Vendor Options | Established: Centorr, Camco Furnace, RD Mathis; Niche: SST; Budget: secondhand dental furnaces |

Ready to elevate your laboratory's capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, medical, and electronics. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization to meet your unique experimental needs precisely. Don't settle for less; contact us today to discuss how we can optimize your material processing and boost efficiency!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What safety precautions and maintenance requirements are necessary for vacuum hot press furnaces? Ensure Safe, Reliable Operation

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity