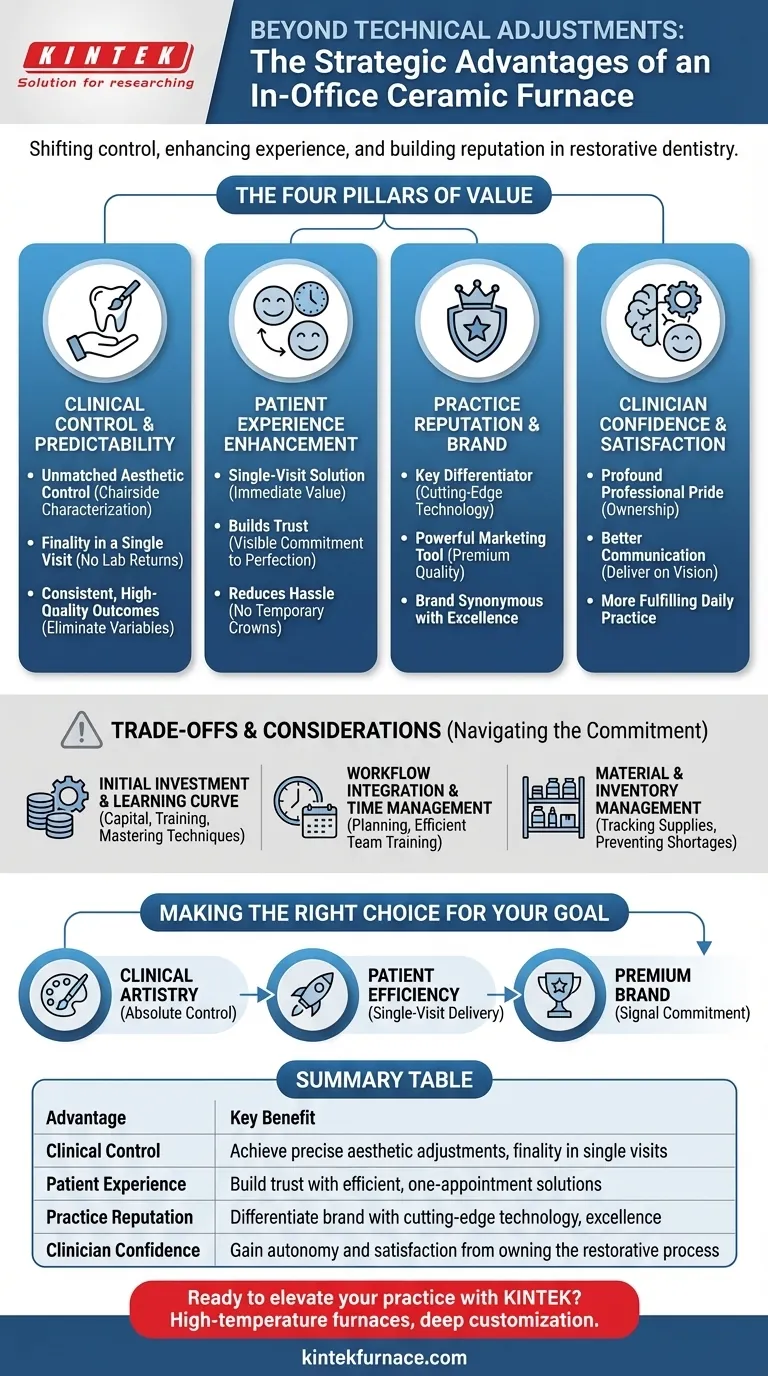

Beyond simple technical adjustments, an in-office ceramic furnace fundamentally changes the dynamic of restorative dentistry. It shifts the locus of control over the final aesthetic outcome directly into the clinician's hands, which in turn enhances clinical confidence, improves the patient experience, and strengthens the practice's reputation for excellence.

The true value of an in-office furnace is not just the ability to modify a restoration, but the power to own the entire restorative process. This control is the foundation for achieving superior predictability, building deeper patient trust, and fostering profound professional satisfaction.

Elevating Clinical Control and Predictability

The most significant advantage of an in-office furnace is the finality it provides. It transforms the restorative process from a series of dependencies into a streamlined, clinician-controlled workflow.

Gaining Unmatched Aesthetic Control

An in-office furnace allows for chairside characterization. You can add stains, adjust the glaze, and perfect the incisal translucency to precisely match the patient's adjacent teeth.

This moves the process from a mere technical procedure to an artistic endeavor, giving you direct control over the final look and feel of the restoration.

Ensuring Finality in a Single Visit

Without a furnace, a restoration that is close-but-not-perfect must be sent back to the lab, requiring a second appointment for the patient.

With a furnace, minor adjustments to shade, contacts, or contour can be made in minutes. This allows you to deliver the definitive restoration in a single, efficient visit, respecting the patient's time and eliminating the uncertainty of a return trip.

Achieving Consistent, High-Quality Outcomes

Relying on an external lab introduces variables you cannot control, from shipping delays to different technicians interpreting your prescription.

By handling the final firing and glazing yourself, you eliminate these variables. This ensures that every restoration meets your personal standard of quality, leading to highly predictable and repeatable results.

Strengthening Patient Relationships and Practice Reputation

The clinical benefits of an in-office furnace create powerful ripple effects that enhance the business and brand of your practice.

Enhancing the Patient Experience

Patients immediately recognize the value of a single-visit solution. Avoiding a second appointment and the hassle of a temporary crown is a significant and tangible benefit.

When patients see you personally applying the finishing touches to their new tooth, it builds immense trust and demonstrates a commitment to perfection they can see and appreciate.

Building a Reputation for Excellence

An in-office furnace is a key differentiator. It signals that your practice is invested in cutting-edge technology and dedicated to providing the highest standard of care.

This capability becomes a powerful marketing tool, attracting discerning patients who seek premium quality and clinical efficiency. It helps build a brand synonymous with excellence and predictability.

Fostering Clinician Confidence

There is a profound sense of professional pride that comes from delivering a perfectly integrated restoration without outside assistance.

This confidence translates into better communication with patients and a more fulfilling daily practice. It eliminates the frustration of compromised results and empowers you to deliver on your clinical vision every time.

Understanding the Trade-offs and Considerations

While powerful, integrating a furnace requires a clear-eyed assessment of the commitment. Objectivity demands acknowledging the associated responsibilities.

The Initial Investment and Learning Curve

A dental furnace represents a significant capital investment. Beyond the purchase price, there is a learning curve associated with mastering different firing cycles, materials, and staining techniques.

Proper training for the clinician and team is essential to unlock the furnace's full potential and ensure a positive return on investment.

Workflow Integration and Time Management

Adding a new step to your chairside workflow requires careful planning. While it saves the patient a second visit, the staining and firing process itself adds time to the single appointment.

Your team must be trained to manage this process efficiently so it doesn't create a bottleneck in your schedule.

Material and Inventory Management

Bringing glazing and staining in-house means you are now responsible for managing an inventory of ceramic materials, stains, glazes, and associated liquids.

This requires an organized system to track supplies and prevent shortages that could disrupt your restorative procedures.

Making the Right Choice for Your Goal

Integrating a furnace should align directly with your primary practice objectives.

- If your primary focus is clinical artistry and autonomy: The furnace is an essential tool for gaining absolute control over the final aesthetic outcome of your restorations.

- If your primary focus is patient experience and efficiency: The furnace is the key to delivering single-visit restorations, eliminating return appointments for adjustments and dramatically increasing patient satisfaction.

- If your primary focus is building a premium brand: Owning the final step of the restorative process serves as a powerful signal of your commitment to quality and differentiates your practice from the competition.

Ultimately, an in-office furnace empowers you to take complete ownership of the final product you deliver to your patients.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Clinical Control | Achieve precise aesthetic adjustments and finality in single visits |

| Patient Experience | Build trust with efficient, one-appointment solutions |

| Practice Reputation | Differentiate your brand with cutting-edge technology and excellence |

| Clinician Confidence | Gain autonomy and satisfaction from owning the restorative process |

Ready to elevate your dental practice with advanced ceramic furnace solutions? KINTEK offers high-temperature furnaces like Muffle, Tube, and Rotary Furnaces, backed by deep customization to meet your unique needs. Contact us today to enhance control, efficiency, and patient satisfaction!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations