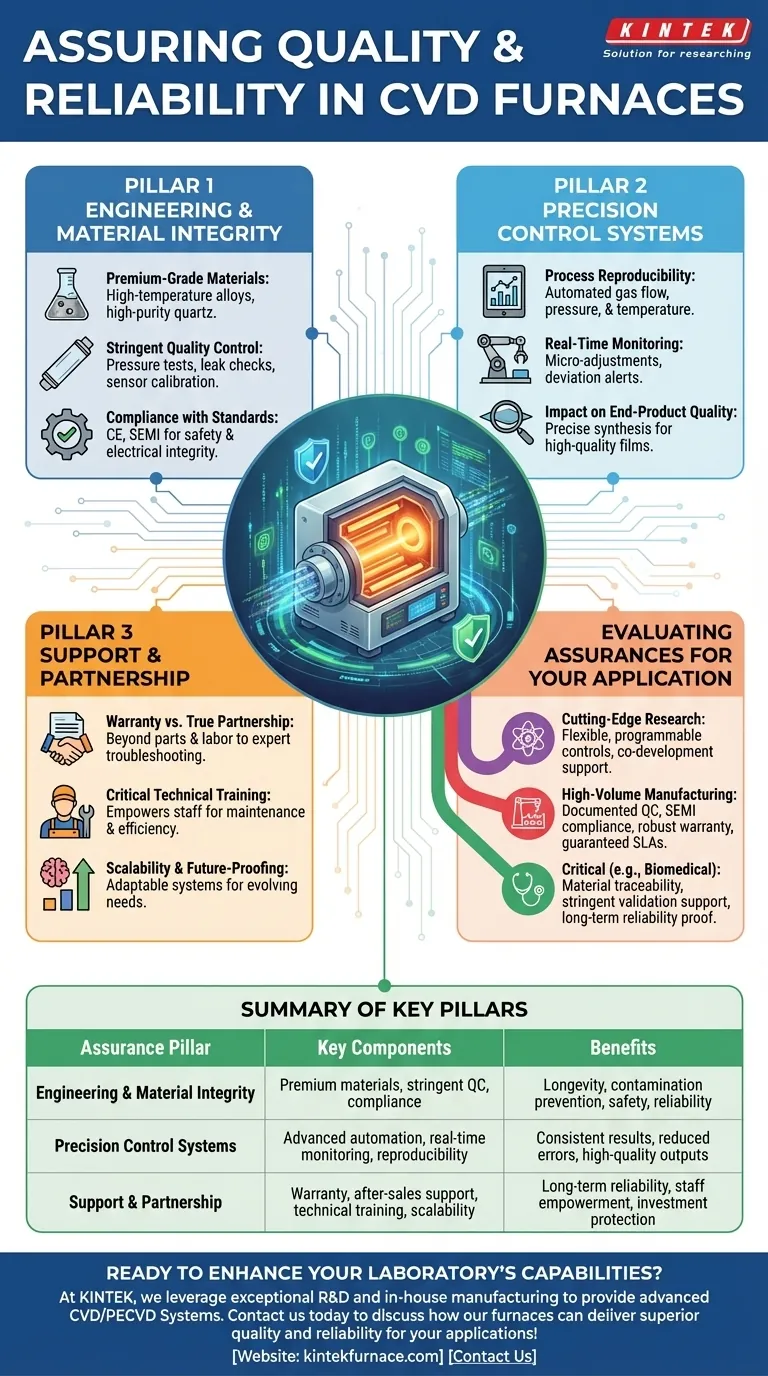

The quality and reliability of a Chemical Vapor Deposition (CVD) furnace are ensured through a combination of five key pillars. These include the use of premium-grade materials and components, adherence to stringent quality control standards, compliance with international regulations, a comprehensive warranty with after-sales support, and ongoing technical assistance for your team.

True assurance for a CVD furnace is not a single feature but a multi-layered system. It is the integration of robust physical engineering, precise digital process control, and a long-term support commitment from the manufacturer.

The Foundation: Engineering and Material Integrity

The reliability of any advanced system begins with its physical construction. For a CVD furnace, which operates in extreme environments, this foundation is non-negotiable.

Premium-Grade Materials and Components

A furnace's ability to perform consistently depends entirely on the quality of its parts. Manufacturers provide assurance by using materials designed for high-temperature, high-purity environments, such as specific metal alloys and high-purity quartz tubes, ensuring longevity and preventing contamination.

Stringent Quality Control (QC)

Reputable manufacturers implement rigorous QC protocols that go beyond a simple final inspection. This includes pressure and leak testing of gas lines, calibration of temperature sensors (thermocouples), and stress testing of critical components to guarantee they meet or exceed operational demands.

Compliance with Industry Standards

Adherence to international standards like CE (for Europe) or SEMI (for the semiconductor industry) is a critical assurance. This compliance certifies that the furnace meets established benchmarks for safety, electrical integrity, and operational best practices, facilitating integration into regulated facilities.

The Core of Reliability: Precision Control Systems

A robust physical build is only half the equation. The operational reliability and quality of the final product are dictated by the furnace's control system.

Ensuring Process Reproducibility

The primary goal of a production or research process is achieving the same result every time. Modern CVD furnaces are equipped with advanced control systems that automate gas flow, pressure, and temperature profiles, eliminating manual variability and ensuring high reproducibility between runs.

Real-Time Monitoring and Automation

These systems provide assurance through real-time monitoring of all critical parameters. This allows the system to make micro-adjustments automatically or alert operators to deviations, preventing costly batch failures and reducing reliance on operator skill for routine tasks.

Impact on End-Product Quality

The ability to precisely control the synthesis process is what enables the creation of high-quality thin films. Whether for semiconductors or biocompatible coatings on medical devices, this precision is a direct assurance of the furnace's capability to deliver the required outcome.

Understanding the Trade-offs: Support and Partnership

The most common pitfall in acquiring complex equipment is underestimating the human element. The best hardware can fail without proper knowledge and support.

Warranty vs. True Partnership

A warranty is a baseline assurance that covers parts and labor. However, a comprehensive after-sales support agreement signifies a deeper partnership. This includes access to expert technicians who understand your process and can help troubleshoot application-specific challenges, not just hardware faults.

The Critical Role of Technical Training

A furnace is only as reliable as the team operating it. An essential assurance from the manufacturer is the provision of ongoing technical training. This empowers your staff to perform routine maintenance, diagnose minor issues, and operate the equipment for maximum efficiency and longevity.

Scalability and Future-Proofing

A reliable furnace is one that remains valuable as your needs evolve. Look for systems with strong scalability, meaning they can be adapted or upgraded for new processes or materials. This is a form of long-term assurance on your initial investment.

How to Evaluate Assurances for Your Application

To de-risk your investment, you must align the manufacturer's assurances with your specific operational goals.

- If your primary focus is cutting-edge research: Prioritize furnaces with highly flexible, programmable control systems and a strong technical support team for co-development and process optimization.

- If your primary focus is high-volume manufacturing: Emphasize documented QC processes, compliance with SEMI standards, and a robust warranty with guaranteed service-level agreement (SLA) response times.

- If your primary focus is a critical application (e.g., biomedical): Demand proof of material traceability for all wetted parts, stringent process validation support, and case studies demonstrating long-term operational reliability.

Ultimately, the best assurance comes from choosing a partner whose commitment to engineering excellence matches the critical nature of your work.

Summary Table:

| Assurance Pillar | Key Components | Benefits |

|---|---|---|

| Engineering & Material Integrity | Premium-grade materials, stringent QC, compliance with standards | Longevity, contamination prevention, safety, and reliability |

| Precision Control Systems | Advanced automation, real-time monitoring, reproducibility | Consistent results, reduced errors, high-quality outputs |

| Support & Partnership | Warranty, after-sales support, technical training, scalability | Long-term reliability, staff empowerment, investment protection |

Ready to enhance your laboratory's capabilities with a reliable CVD furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met precisely. Contact us today to discuss how our furnaces can deliver superior quality and reliability for your applications!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties