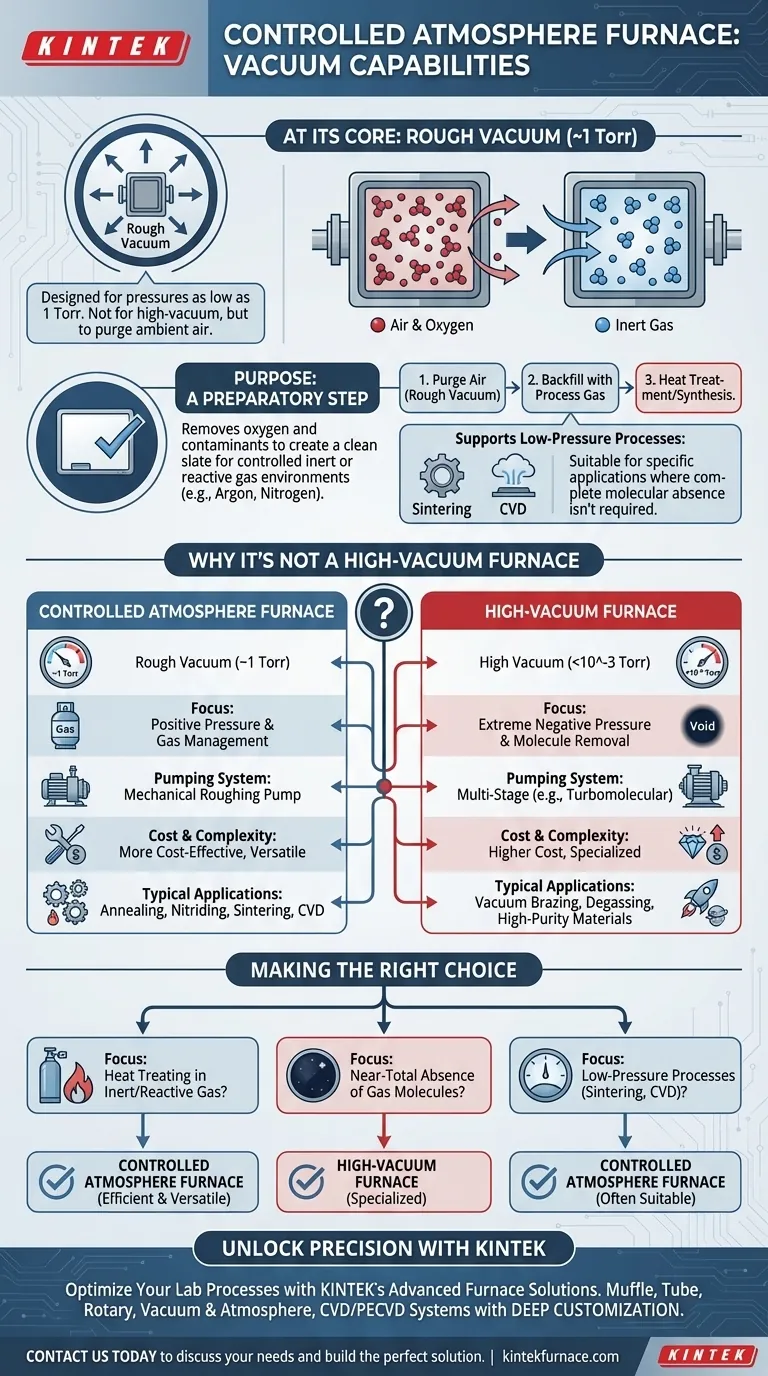

At its core, a controlled atmosphere furnace is designed to provide a rough vacuum, typically reaching pressures as low as 1 Torr. This capability is not intended for high-vacuum applications but serves a critical function: purging the chamber of ambient air before introducing a specific, controlled gas environment for processes like heat treatment or material synthesis.

The vacuum function of a controlled atmosphere furnace is a preparatory step, not the primary processing condition. Its purpose is to create a clean slate by removing oxygen and other atmospheric contaminants, enabling precise control over the subsequent inert or reactive gas atmosphere.

What "Rough Vacuum" Means in This Context

A vacuum level of 1 Torr is considered a low or rough vacuum. Understanding its intended role is key to using the furnace effectively. It is a means to an end—the perfect gas atmosphere—rather than the end itself.

The Primary Goal: Purging the Chamber

Before any heat treatment can begin, the ambient air inside the furnace chamber must be removed. This air, containing roughly 21% oxygen and 78% nitrogen, would react with most materials at high temperatures, causing unwanted oxidation and altering material properties.

Pulling a rough vacuum efficiently removes the vast majority of these reactive gases. The chamber is then backfilled with a high-purity process gas, such as argon, nitrogen, or hydrogen, creating the desired inert or reactive environment.

Supporting Low-Pressure Processes

Some specialized processes, like certain types of chemical vapor deposition (CVD) or sintering, operate optimally under low pressure. The furnace's ability to hold a steady vacuum at this level is sufficient for applications where the complete absence of molecules is not required.

Why It's Not a High-Vacuum Furnace

It is crucial to distinguish a controlled atmosphere furnace from a dedicated high-vacuum furnace. Their design philosophies, components, and applications are fundamentally different.

Design Focus: Gas Control vs. Molecule Removal

A controlled atmosphere furnace is engineered for positive pressure and gas management. Its seals are designed to keep the controlled atmosphere in and the outside air out.

A high-vacuum furnace is engineered for extreme negative pressure. Its goal is to remove as many gas molecules as possible from the chamber, creating a near-void. This requires more robust construction, different sealing mechanisms, and advanced pumping systems.

Pumping and Sealing Limitations

To achieve high or ultra-high vacuum, a system needs multi-stage pumping, typically involving a roughing pump paired with a turbomolecular or diffusion pump.

A controlled atmosphere furnace uses only a mechanical roughing pump, which is incapable of reaching pressures much lower than 1 Torr. Its seals and materials are optimized for containing specific gases at high temperatures, not for the rigors of maintaining a deep vacuum.

Understanding the Trade-offs

Choosing between these furnace types involves balancing capability against cost and complexity.

Versatility vs. Specialization

A controlled atmosphere furnace is a versatile tool for a wide range of thermal processes involving specific gas environments, from annealing and hardening to nitriding and sintering.

A high-vacuum furnace is a highly specialized instrument. It excels at processes that are impossible in the presence of any gas, such as vacuum brazing, degassing, or producing extremely high-purity materials.

Cost and Chamber Size

High-vacuum systems are significantly more expensive and complex. The advanced pumps, gauges, and robust chamber construction required to achieve and measure deep vacuum levels add substantial cost.

Controlled atmosphere furnaces offer a more cost-effective solution for the vast majority of heat treatment applications, especially when larger chamber volumes are needed.

Making the Right Choice for Your Process

Your specific application dictates the necessary equipment. Use this framework to guide your decision.

- If your primary focus is heat treating in an inert or reactive gas (e.g., annealing, nitriding, carburizing): A controlled atmosphere furnace is the correct and most efficient tool.

- If your primary focus is a process requiring the near-total absence of gas molecules (e.g., true vacuum brazing, outgassing components for space): You must use a dedicated high-vacuum furnace capable of reaching pressures far below 1 Torr.

- If your primary focus is a low-pressure process like sintering or CVD: A controlled atmosphere furnace is often suitable, as long as your pressure requirements are not below its operational vacuum limit.

Selecting the right furnace begins with a clear understanding of whether your process needs a controlled gas or the absence of it.

Summary Table:

| Feature | Controlled Atmosphere Furnace | High-Vacuum Furnace |

|---|---|---|

| Vacuum Level | Rough vacuum (~1 Torr) | High vacuum (e.g., <10^-3 Torr) |

| Primary Function | Purging air, enabling gas control | Removing gas molecules for near-void conditions |

| Typical Applications | Annealing, nitriding, sintering, CVD | Vacuum brazing, degassing, high-purity material production |

| Pumping System | Mechanical roughing pump | Multi-stage pumps (e.g., turbomolecular) |

| Cost and Complexity | More cost-effective, versatile | Higher cost, specialized |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Are you optimizing heat treatment or material synthesis processes? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to meet your unique experimental needs.

Contact us today to discuss how our controlled atmosphere and vacuum furnaces can enhance your efficiency and results—let's build the perfect solution for your lab!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing