At its core, a laboratory furnace is a high-precision oven for controlled thermal processing. Its uses span a vast range of scientific and industrial applications, from altering the physical properties of metals through annealing and sterilizing medical equipment to synthesizing advanced nanomaterials and analyzing the composition of a sample. The furnace is a fundamental tool for any process that requires uniform, stable temperatures well beyond the capabilities of a standard oven.

A laboratory furnace is not simply a device for generating heat. It is an instrument for precisely controlling a material's environment to induce specific, repeatable chemical or physical transformations, forming the bedrock of modern materials science, chemistry, and electronics research.

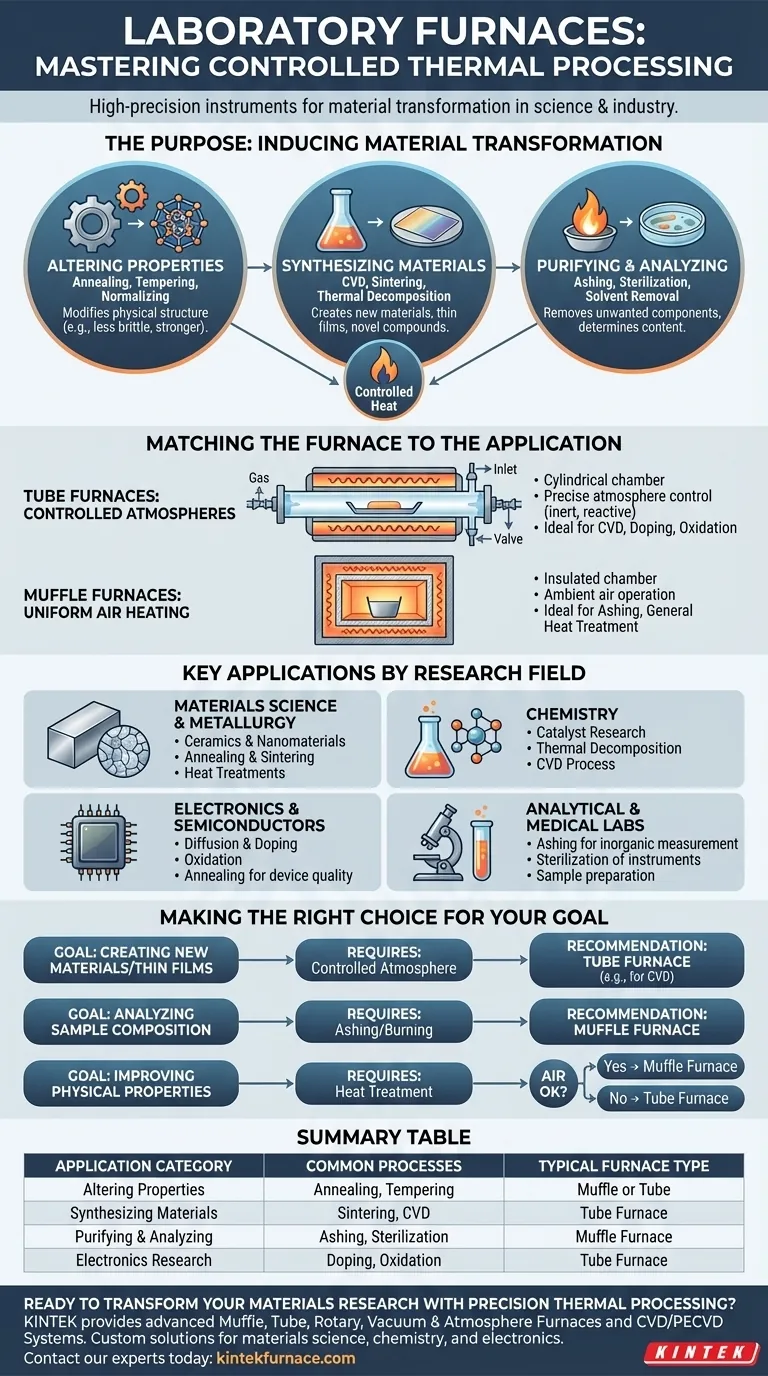

The Purpose: Inducing Material Transformation

The primary function of any laboratory furnace is to use heat to purposefully change a material. These transformations can be broadly categorized into altering, creating, or purifying a substance.

Altering Physical Properties

Many applications, such as annealing, tempering, or normalizing, use heat to change a material's internal structure. This modifies its physical properties—for example, making a metal less brittle and more ductile (malleable) or strengthening a ceramic component.

Synthesizing New Materials

Furnaces are essential for creating materials that do not exist naturally. This includes processes like Chemical Vapor Deposition (CVD) to create thin films on a substrate, sintering to fuse powders into a solid mass, or thermal decomposition to produce novel compounds like oxides and carbides.

Purifying and Analyzing Samples

Heat can be used to remove unwanted components from a sample. This includes solvent removal, polymer curing, and ashing, a critical process where a sample is burned to determine its non-combustible, inorganic content. Furnaces are also used for high-temperature sterilization.

Matching the Furnace to the Application

While all furnaces heat, different designs are optimized for specific tasks. The two most common types are muffle furnaces and tube furnaces, distinguished primarily by how they contain the sample and its atmosphere.

Tube Furnaces: For Controlled Atmospheres

A tube furnace heats a cylindrical chamber (often made of ceramic or quartz) through which a sample is passed or placed.

Its key advantage is the ability to precisely control the gaseous atmosphere around the sample. This is critical for processes like CVD, catalyst research, and semiconductor doping and oxidation, where reactions with air must be prevented.

Muffle Furnaces: For Uniform Air Heating

A muffle furnace heats a chamber of insulating material, protecting the sample from direct contact with the heating elements. It typically operates with the ambient air inside the chamber.

These furnaces are workhorses for general-purpose heat treatment, ashing samples to determine inorganic content, and other applications where a specific gas atmosphere is not required.

Key Applications by Research Field

The specific use of a furnace is highly dependent on the scientific objective and field of study.

In Materials Science & Metallurgy

Furnaces are indispensable for both creating and testing new materials. Common uses include synthesizing ceramics and nanomaterials, performing heat treatments like annealing, and sintering powdered metals and ceramics into solid components.

In Chemistry

Chemical research uses furnaces to drive reactions at high temperatures. This is seen in catalyst research to evaluate activity, thermal decomposition studies, and the CVD process for depositing thin films.

In Electronics & Semiconductors

The manufacturing of microchips is heavily reliant on furnace processing. They are used for diffusion and doping to alter the electrical properties of silicon wafers and for oxidation and annealing steps that improve the quality and performance of the final device.

In Analytical & Medical Labs

In these settings, furnaces are primarily used for sample preparation and sterilization. Ashing is the most common analytical use, allowing researchers to measure the non-volatile portion of a sample. They are also used for sterilizing instruments that can withstand high heat.

Making the Right Choice for Your Goal

Selecting the correct furnace process is critical for achieving your desired outcome. Your decision should be guided by the fundamental transformation you intend to cause.

- If your primary focus is creating new materials or thin films: You will likely need a tube furnace for its ability to control the gaseous atmosphere, which is essential for processes like CVD.

- If your primary focus is analyzing the composition of a sample: A muffle furnace is the standard tool for ashing, which cleanly burns away organic matter to isolate the inorganic residue for measurement.

- If your primary focus is improving the physical properties of a material: Both furnace types can be used for heat treatment like annealing, but the choice depends on whether the material must be protected from air during the process.

Ultimately, a laboratory furnace provides the controlled thermal environment necessary to manipulate matter at a fundamental level.

Summary Table:

| Application Category | Common Processes | Typical Furnace Type |

|---|---|---|

| Altering Properties | Annealing, Tempering, Normalizing | Muffle or Tube Furnace |

| Synthesizing Materials | Sintering, Chemical Vapor Deposition (CVD) | Tube Furnace |

| Purifying & Analyzing | Ashing, Sterilization, Polymer Curing | Muffle Furnace |

| Electronics Research | Doping, Oxidation, Diffusion | Tube Furnace |

Ready to transform your materials research with precision thermal processing?

At KINTEK, we understand that your experiments demand more than just heat—they require precise control and repeatability. Our advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and specialized CVD/PECVD Systems, are engineered to meet the rigorous demands of modern laboratories.

Leveraging exceptional R&D and in-house manufacturing, we provide strong deep customization capabilities to precisely match your unique experimental requirements, whether you are in materials science, chemistry, or electronics.

Contact our experts today to discuss how a KINTEK furnace can become the bedrock of your next breakthrough.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure