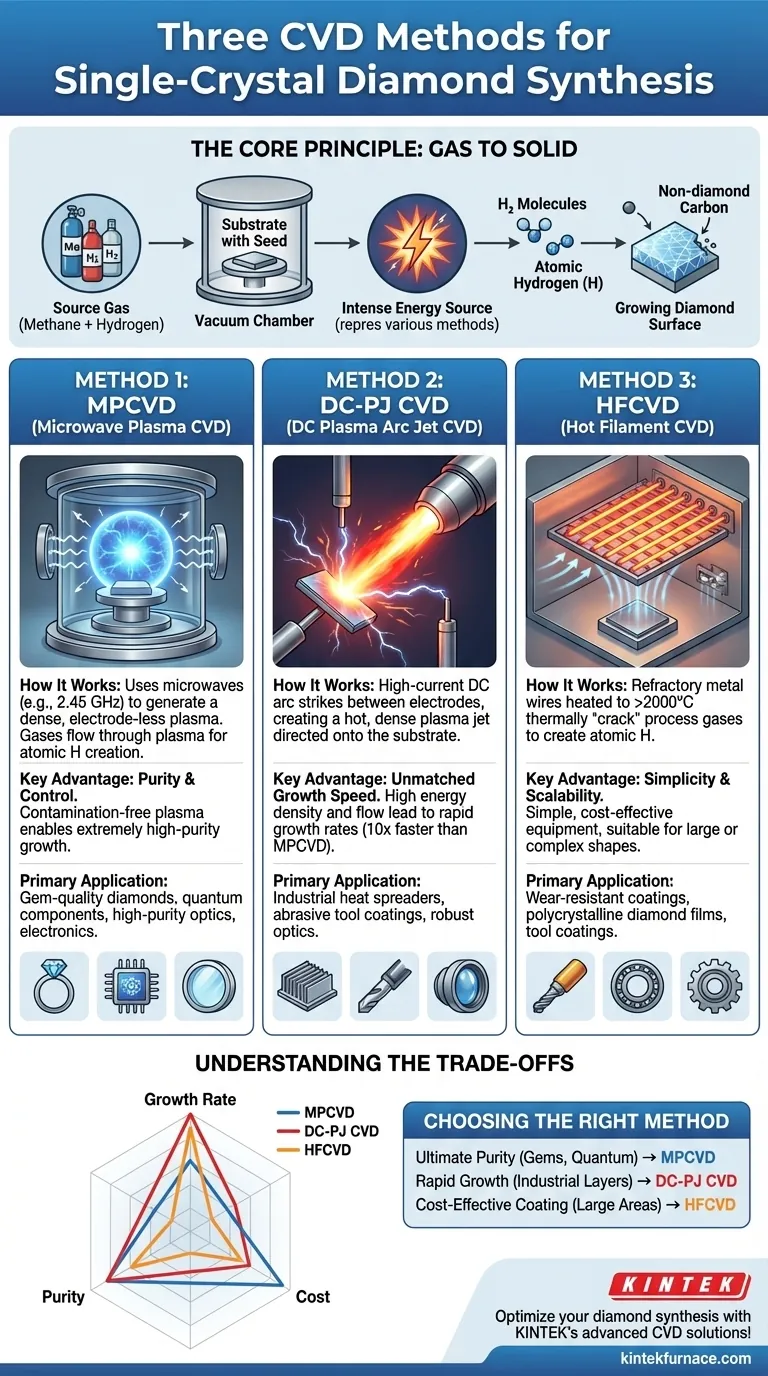

When synthesizing single-crystal diamonds via Chemical Vapor Deposition (CVD), three primary methods are employed. These are Microwave Plasma CVD (MPCVD), DC Plasma Arc Jet CVD (DC-PJ CVD), and Hot Filament CVD (HFCVD). Each technique uses a different approach to energize a carbon-source gas, leading to distinct advantages in growth rate, crystal quality, and operational cost.

The choice between diamond CVD methods is a strategic decision based on a fundamental trade-off. MPCVD is the industry standard for high-purity applications, DC-PJ CVD excels at high-speed industrial growth, and HFCVD offers a simpler, lower-cost alternative often used for coatings.

The Core Principle of Diamond CVD

To understand the methods, we must first understand the fundamental process they all share. The goal is to deposit carbon atoms in a diamond (sp³) lattice rather than a graphite (sp²) lattice.

From Gas to Solid

The process begins with a source gas, typically methane (CH₄), which provides the carbon, mixed with a large excess of hydrogen gas (H₂). This mixture is fed into a vacuum chamber containing a substrate, often a small, high-quality diamond seed.

The Role of Energy

The key to forming diamond is to break the stable H₂ molecules into highly reactive atomic hydrogen (H). Each of the three CVD methods is simply a different way to supply the intense energy required to achieve this dissociation.

Atomic Hydrogen's Critical Job

This atomic hydrogen is the hero of the process. It preferentially etches away any non-diamond carbon (graphite) that forms, leaving only the more stable diamond crystal behind. It also stabilizes the growing diamond surface, allowing carbon atoms from the methane to attach correctly.

Method 1: Microwave Plasma CVD (MPCVD)

MPCVD is the dominant method for producing high-quality, single-crystal diamonds for gems and advanced technical applications.

How It Works

This method uses microwaves (often at 2.45 GHz, the same frequency as a home microwave oven) to generate a dense, stable ball of plasma inside the reaction chamber. The process gases flow through this plasma, which efficiently creates the necessary atomic hydrogen.

Key Advantage: Purity and Control

Because the plasma is contained by an electromagnetic field and does not touch any electrodes, the risk of contamination is virtually zero. This "electrodeless" nature allows for the growth of extremely high-purity diamonds with exceptional color and clarity.

Primary Application

MPCVD is the go-to method for gem-quality diamonds, high-frequency electronics, quantum computing components, and pristine optical windows. The process prioritizes quality and control over raw speed.

Method 2: DC Plasma Arc Jet CVD (DC-PJ CVD)

When speed is the primary requirement, DC Plasma Arc Jet is the method of choice.

How It Works

A high-current DC electrical arc is struck between two electrodes, creating an extremely hot and dense plasma. This plasma is then shot out of a nozzle as a high-velocity "jet" directly onto the diamond substrate.

Key Advantage: Unmatched Growth Speed

The immense energy density and high gas flow of the jet result in extraordinarily fast growth rates. These can be more than ten times faster than typical MPCVD processes, enabling the rapid production of thick diamond layers.

Primary Application

DC-PJ CVD is used for industrial applications where thickness and throughput are critical. This includes manufacturing thick heat spreaders for electronics, abrasive tool coatings, and robust industrial optics.

Method 3: Hot Filament CVD (HFCVD)

Also known as Hot Wire CVD, this method is the simplest and often most cost-effective of the three.

How It Works

A grid of refractory metal wires, such as tungsten or tantalum, is heated electrically to over 2000°C. The process gases pass over these glowing hot filaments and are thermally "cracked," creating atomic hydrogen.

Key Advantage: Simplicity and Scalability

The equipment for HFCVD is relatively simple and inexpensive compared to plasma-based systems. It is also well-suited for coating large or complex-shaped objects, making it a workhorse for industrial coatings.

Primary Application

HFCVD is primarily used for depositing polycrystalline diamond films on cutting tools, bearings, and other wear-resistant surfaces. Its use for high-purity single-crystal growth is limited by the potential for the filament material to contaminate the diamond.

Understanding the Trade-offs: A Direct Comparison

No single method is universally superior; the best choice depends entirely on the end goal.

Growth Rate vs. Quality

DC-PJ CVD is the fastest, but the violent process can introduce more structural defects. MPCVD is significantly slower but yields the highest crystal quality and purity. HFCVD sits somewhere in the middle but is rarely the first choice for top-tier single crystals.

Purity and Contamination

MPCVD is the cleanest process due to its electrodeless plasma. DC-PJ CVD risks minor contamination from electrode erosion over time. HFCVD is the most susceptible to contamination, as atoms from the hot filament can incorporate into the growing diamond, affecting its properties.

Cost and Complexity

HFCVD is the simplest and most affordable system to build and operate. MPCVD systems are more complex and represent a moderate-to-high capital investment. DC-PJ CVD systems are highly complex and energy-intensive, reserved for specialized high-throughput industrial production.

Choosing the Right Method for Your Goal

Your application's requirements for purity, speed, and cost will dictate the optimal synthesis method.

- If your primary focus is ultimate purity and quality (gemstones, quantum devices): MPCVD is the undisputed standard due to its contamination-free plasma environment.

- If your primary focus is rapid growth for industrial applications (heat sinks, thick layers): DC-PJ CVD offers the highest deposition rates, prioritizing speed over pristine crystal structure.

- If your primary focus is cost-effective coating on large areas: HFCVD provides a simpler, lower-cost entry point, though it is more commonly used for polycrystalline films.

Understanding these core trade-offs empowers you to select the synthesis route that directly aligns with your material performance requirements and economic constraints.

Summary Table:

| Method | Key Advantage | Primary Application |

|---|---|---|

| MPCVD | High purity and control | Gem-quality diamonds, quantum computing, electronics |

| DC-PJ CVD | Unmatched growth speed | Industrial heat spreaders, tool coatings, optics |

| HFCVD | Simplicity and cost-effectiveness | Wear-resistant coatings, large-area films |

Optimize your diamond synthesis with KINTEK's advanced CVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs for superior purity, speed, or cost-efficiency. Contact us today to discuss how our expertise can elevate your research and production outcomes!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth