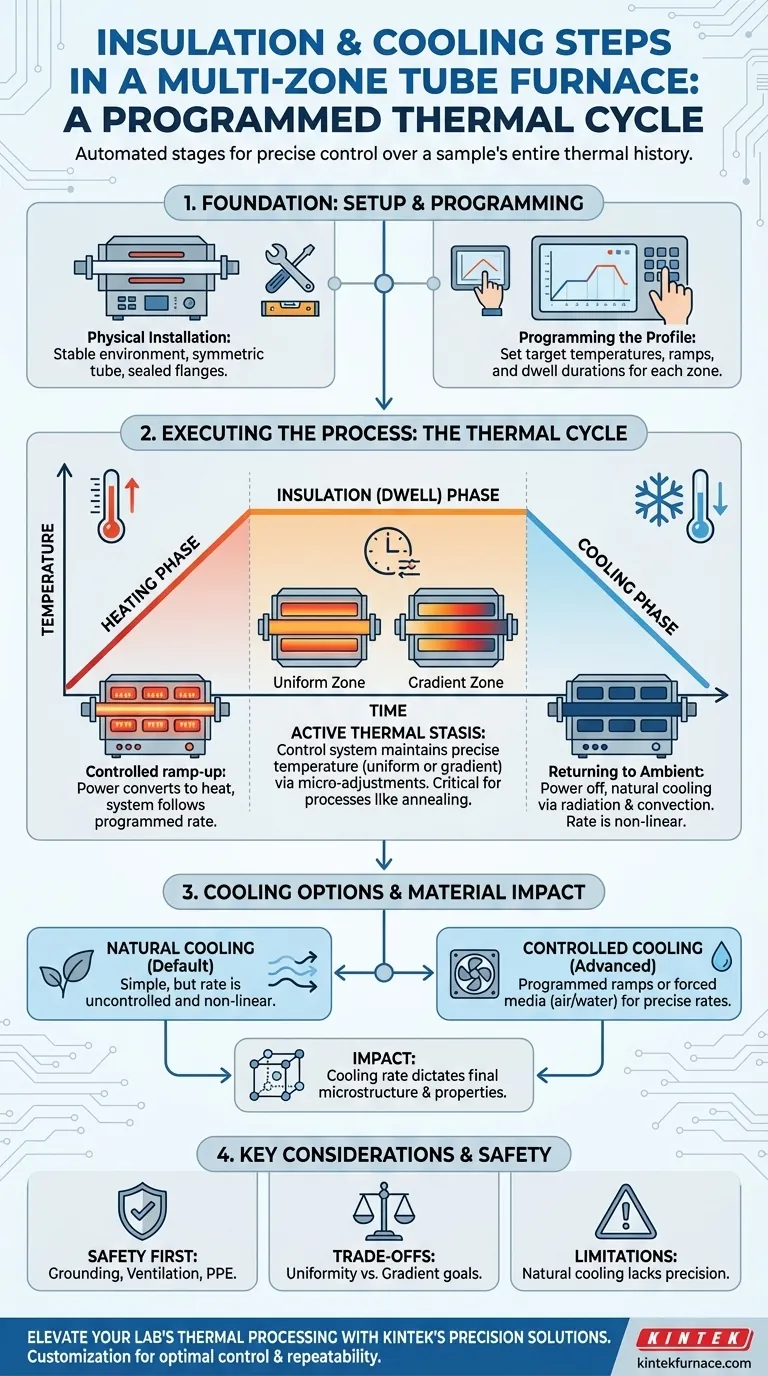

In a multi-zone tube furnace, the insulation and cooling stages are automated steps within a programmed thermal cycle. The insulation phase, more accurately called a "dwell" or "isothermal hold," involves the control system actively maintaining a stable, pre-set temperature profile across all zones for a specified duration. Following this, the cooling phase begins, which typically involves shutting off power to the heating elements and allowing the furnace to return to room temperature naturally.

The core principle is not merely heating and cooling, but precisely controlling the entire thermal history of a sample. The furnace's control system executes a pre-defined program, where the insulation (dwell) and cooling stages are just as critical to the final outcome as the initial heating ramp.

The Foundation: Setup and Programming

Before a thermal cycle can begin, correct physical setup and precise programming are essential for accuracy, repeatability, and safety.

Physical Installation

The furnace must be placed in a stable, well-ventilated environment, free from vibrations, flammable materials, or excessive dust.

The furnace tube is the heart of the system. It must be installed symmetrically, ensuring it does not touch any of the internal heating elements.

Properly sealed flanges are critical for atmosphere control. They must be installed in the correct sequence and tightened evenly to prevent leaks or damage to the tube.

Programming the Thermal Profile

The primary advantage of a multi-zone furnace is the ability to create a highly uniform temperature zone or a precise temperature gradient.

Using the control panel, you will set the target temperature and heating program for each individual zone. This includes the heating rate (ramp), the dwell temperature and duration (insulation), and any controlled cooling steps.

Once programmed, starting the heating system initiates the automated process, which is often visualized as a temperature curve on the controller's display.

Executing the Process: From Heating to Insulation

With the program set, the furnace begins its automated cycle, managed entirely by the temperature control system.

The Heating Phase

The controller sends power to the resistance heating elements in each zone, converting electrical energy into heat.

The system continuously monitors the temperature in each zone, adjusting power to follow the programmed heating ramp until the target setpoints are reached.

The Insulation (Dwell) Phase Explained

This is the stage where the furnace holds the sample at a stable temperature. The term "insulation" in this context refers to maintaining thermal stasis, not physical insulation material.

The control system actively manages the power to each zone, making micro-adjustments to counteract heat loss and maintain the precise temperature profile—whether uniform or a gradient—for the specified duration. This step is critical for processes like annealing, sintering, or crystal growth.

The Cooling Phase: Returning to Ambient

Once the insulation (dwell) time is complete, the heating elements are deactivated, and the furnace begins to cool.

Natural Cooling (The Default)

The most common method is to simply turn off power to the heating system and allow the furnace to cool down naturally via radiation and convection to the surrounding air.

This process is simple and requires no extra equipment, but its rate is non-linear and can be influenced by ambient room temperature.

The Importance of Cooling Rate

For many materials science applications, the rate of cooling is a critical variable that can dramatically affect the final material's microstructure, phase, and properties.

Natural cooling is slow and offers minimal control. The cooling rate will be fast at high temperatures and become progressively slower as the furnace approaches room temperature.

Considerations for Controlled Cooling

While not always standard, some processes require precise control over the cooling rate. This can be achieved through programmed power ramp-downs, where the furnace follows a specific cooling profile.

More advanced systems may incorporate forced air or water-cooling jackets to achieve rapid and controlled cooling (quenching), which is essential for "freezing" a material in a specific high-temperature state.

Understanding the Trade-offs and Safety Protocols

Operating a multi-zone furnace requires an awareness of its capabilities, limitations, and inherent risks.

Uniformity vs. Gradient

The primary programming trade-off is deciding on the thermal profile's goal. Setting all zones to the same temperature creates a long, highly uniform hot zone. Staggering the setpoints creates a specific, stable temperature gradient along the tube's length.

Natural Cooling Limitations

The key limitation of natural cooling is its lack of precision and repeatability. If the exact cooling profile is critical to your experiment, relying on natural cooling may introduce an unacceptable variable.

Critical Safety Checks

Safety is paramount. Always ensure the furnace has effective electrical grounding to prevent shock. The area must have good ventilation, especially when using process gases, to prevent leaks and asphyxiation hazards.

Never exceed the furnace's rated temperature. Wear appropriate personal protective equipment (PPE), such as heat-resistant gloves and safety glasses, when handling hot components.

Achieving Your Experimental Goal

Your approach to these steps should be dictated by your ultimate objective.

- If your primary focus is process repeatability: Pay meticulous attention to programming the exact same profile every time and be aware that ambient conditions can affect natural cooling rates.

- If your primary focus is material synthesis: Recognize that the dwell temperature, dwell duration, and the cooling rate are all critical parameters that influence your final product's properties.

- If your primary focus is operational safety: Prioritize proper installation, grounding, ventilation, and PPE before ever beginning a thermal cycle.

Mastering these stages transforms the furnace from a simple heater into a precision instrument for material processing.

Summary Table:

| Step | Description | Key Points |

|---|---|---|

| Setup & Programming | Prepare furnace and define thermal profile | Stable environment, symmetric tube installation, precise zone programming |

| Heating Phase | Ramp up to target temperature | Controlled power to elements, monitored by system |

| Insulation (Dwell) Phase | Maintain stable temperature | Active power adjustments for uniformity or gradient, critical for processes |

| Cooling Phase | Return to ambient temperature | Natural cooling (default) or controlled methods, rate affects material properties |

| Safety & Considerations | Ensure safe operation and address limitations | Grounding, ventilation, PPE, trade-offs in uniformity vs. gradient |

Ready to elevate your lab's thermal processing? KINTEK specializes in advanced high-temperature furnace solutions, including Tube Furnaces, designed for precision and reliability. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring optimal insulation, cooling control, and repeatability. Contact us today to discuss how our products can enhance your material synthesis and safety protocols!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations