To ensure safety with a heat treatment furnace, you must implement a multi-layered protocol that addresses personal protection, equipment integrity, and the surrounding environment. This involves wearing appropriate heat-resistant Personal Protective Equipment (PPE), verifying all safety mechanisms like shut-off valves and ventilation are functional before startup, and adhering to strict operational rules such as never exceeding the furnace's rated temperature or introducing liquids into the chamber.

The core principle of furnace safety is moving beyond a simple checklist. It requires a systematic approach that manages three distinct hazard categories—thermal, electrical, and chemical—throughout every phase of operation, from preparation to maintenance.

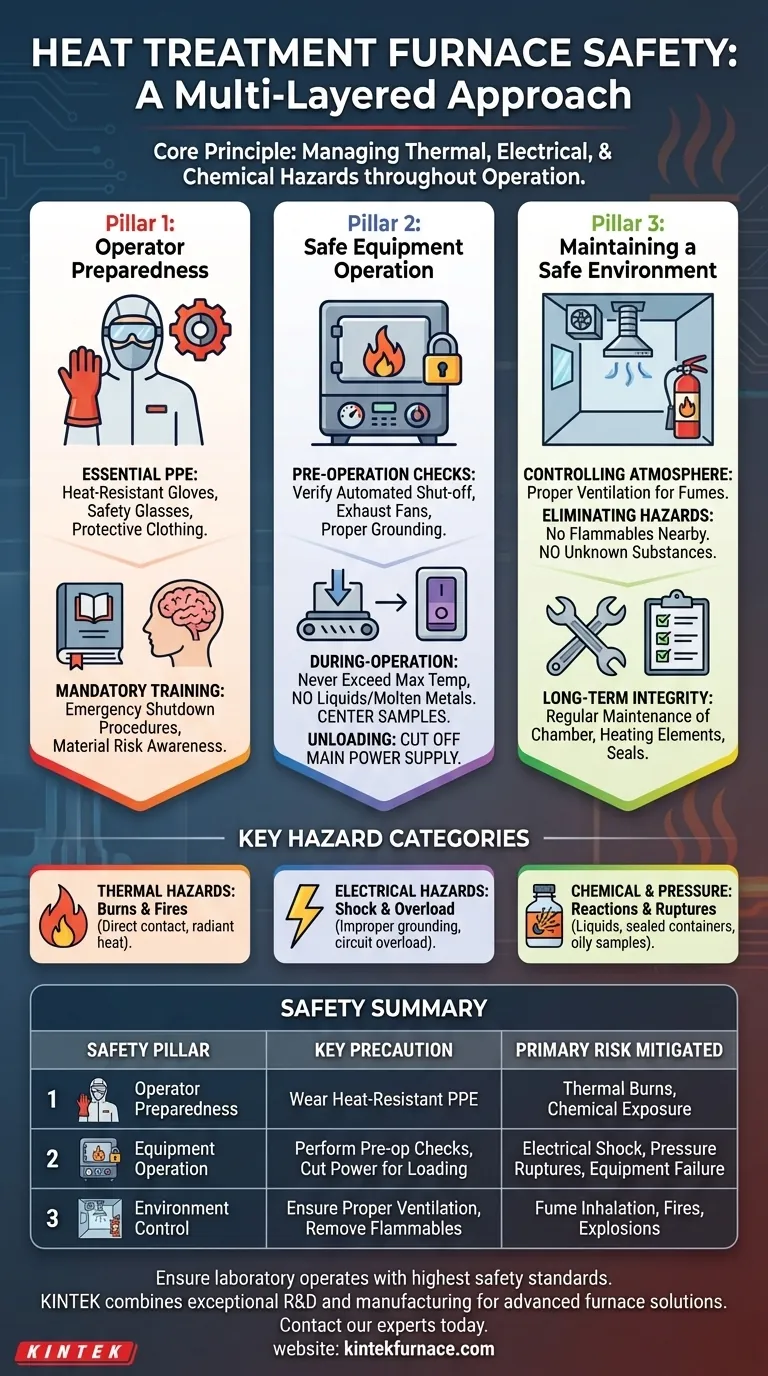

The Three Pillars of Furnace Safety

True safety is not a single action but a constant state of awareness supported by three foundational pillars: the operator, the equipment, and the environment.

Pillar 1: Operator Preparedness

The most critical safety component is a well-trained and properly equipped operator.

Essential Personal Protective Equipment (PPE)

Your first line of defense is what you wear. Non-negotiable PPE includes heat-resistant gloves, safety glasses or a face shield, and durable, non-synthetic protective clothing to shield skin from high temperatures and potential contact with quenching oils.

Mandatory Training

No one should operate a furnace without being fully trained. This includes complete familiarity with the specific model's emergency shutdown procedures and understanding the risks associated with the materials being treated.

Pillar 2: Safe Equipment Operation

How you interact with the furnace directly determines the level of risk during a procedure.

Pre-Operation Safety Checks

Before every use, perform a "pre-flight" check. Confirm that all automated safety devices, such as automatic shut-off valves and exhaust fans, are working correctly. Ensure the furnace is properly grounded to prevent electrical shock.

During-Operation Protocols

Never exceed the furnace's maximum rated temperature, as this can damage heating elements and the furnace lining. It is strictly prohibited to pour any liquids or molten metals directly into the furnace chamber, which can cause violent reactions or pressure buildup.

For consistent and safe heating, place samples neatly in the center of the furnace. Minimize the time the furnace door is open to maintain thermal stability and reduce heat exposure to the operator and the room.

Loading and Unloading

Always cut off the main power supply when loading or unloading materials. This simple step prevents the risk of electrical shock and accidental heating element activation.

Pillar 3: Maintaining a Safe Environment

The area around the furnace is just as important as the furnace itself.

Controlling the Atmosphere

Proper ventilation is essential to dissipate heat and remove any fumes generated during the process, especially when working with oily parts or specific alloys.

Eliminating Fire and Explosion Hazards

Store no flammable or explosive materials near the furnace. Never attempt to heat unknown or potentially reactive substances inside the furnace, as this can lead to catastrophic failure.

Ensuring Long-Term Integrity

Regular maintenance is a proactive safety measure. This includes routine inspection and cleaning of the vacuum chamber, heating elements, and seals to ensure the equipment operates as designed and without failure.

Understanding Key Hazard Categories

Many safety rules exist to mitigate three primary types of danger. Understanding them helps reinforce why the procedures are so critical.

Thermal Hazards: Burns and Fires

The most obvious risk is the extreme heat. Direct contact causes severe burns, while radiant heat can ignite nearby combustible materials. This is why minimizing door opening time and keeping the surrounding area clear is paramount.

Electrical Hazards: Shock and Overload

Heat treatment furnaces are high-power devices. Improper grounding or a faulty power supply creates a severe risk of electric shock. Using a dedicated electrical gate prevents overloading circuits, which can lead to electrical fires.

Chemical and Pressure Hazards: Reactions and Ruptures

Introducing liquids or sealed containers into a hot furnace can cause them to flash into steam or gas, creating a sudden and dangerous pressure buildup. Likewise, oily samples can produce excessive smoke or even ignite, creating a fire hazard within the chamber.

Making the Right Choice for Your Goal

Your role determines which safety aspects demand the most focus.

- If your primary focus is daily operation: Prioritize the pre-operation checklist and the consistent use of all required PPE.

- If your primary focus is facility management: Concentrate on scheduled maintenance, ensuring proper electrical grounding, and enforcing a strict exclusion zone for flammable materials.

- If your primary focus is training new personnel: Emphasize the emergency shutdown procedure and the "why" behind the rules, ensuring they understand the thermal, electrical, and chemical risks involved.

By treating furnace operation with a disciplined and systematic approach, you transform a high-risk process into a controlled and productive one.

Summary Table:

| Safety Pillar | Key Precaution | Primary Risk Mitigated |

|---|---|---|

| Operator Preparedness | Wear heat-resistant gloves, safety glasses, and protective clothing. | Thermal burns, chemical exposure. |

| Equipment Operation | Perform pre-operation checks; never exceed max temperature or introduce liquids. | Electrical shock, pressure ruptures, equipment failure. |

| Environment Control | Ensure proper ventilation and store no flammable materials nearby. | Fume inhalation, fires, explosions. |

Ensure your laboratory operates with the highest safety standards. A reliable furnace is the foundation of safe heat treatment. At KINTEK, we combine exceptional R&D and in-house manufacturing to provide advanced, high-temperature furnace solutions—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your equipment precisely meets your unique experimental requirements, integrating seamlessly with your safety protocols. Contact our experts today to discuss how a KINTEK furnace can enhance both the safety and productivity of your lab.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing