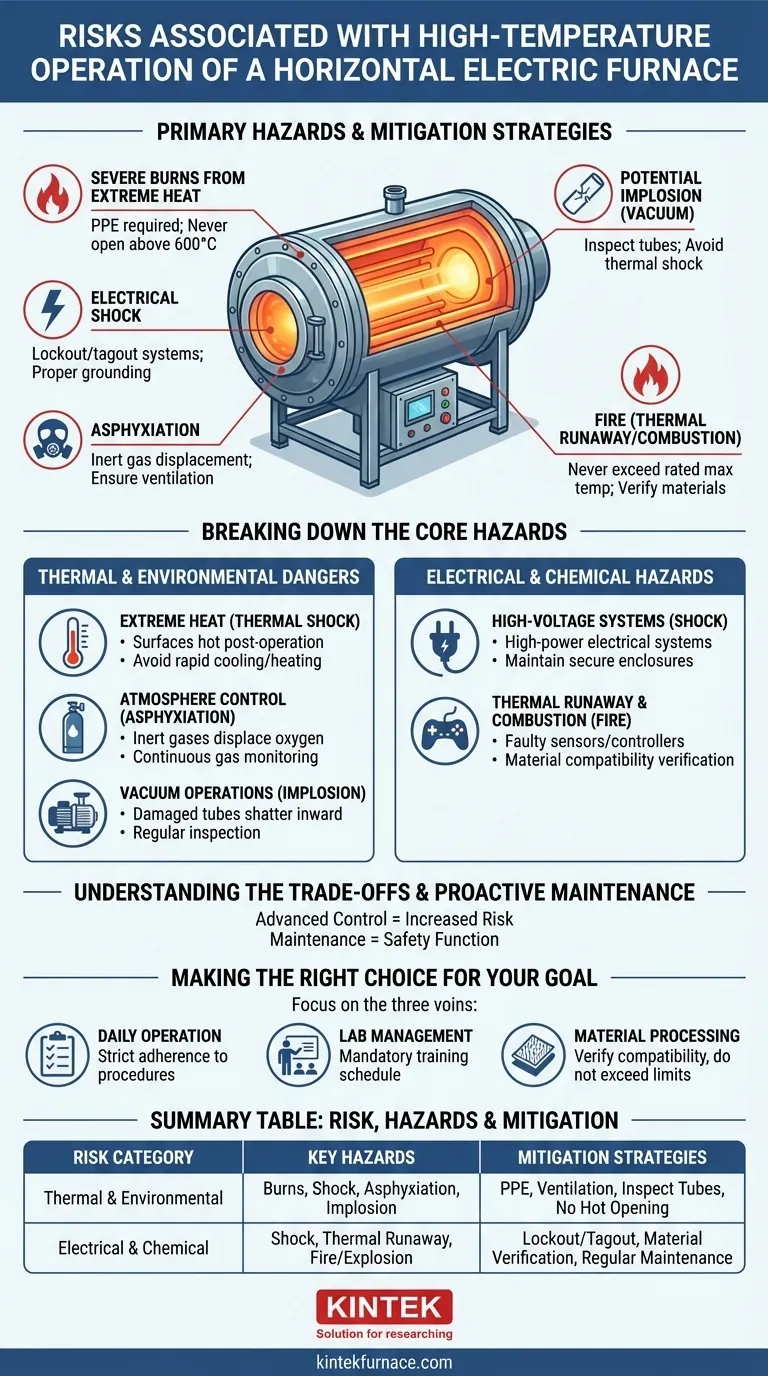

Operating a high-temperature horizontal furnace involves significant risks that demand rigorous safety protocols. The primary hazards include severe burns from extreme heat, electrical shock from high-power systems, asphyxiation from inert gas displacement of oxygen, potential furnace implosion when under vacuum, and fire due to thermal runaway or the combustion of processed materials.

The inherent dangers of high-temperature furnace operation are entirely manageable, but only through a disciplined approach. This requires a synthesis of equipment understanding, strict operational procedures, and a proactive maintenance culture.

Breaking Down the Core Hazards

A horizontal furnace is a specialized tool, and its primary risks stem directly from the extreme conditions it creates. Understanding each hazard vector is the first step toward mitigation.

Thermal and Environmental Dangers

The most immediate dangers relate to the furnace's internal environment: its temperature and atmosphere.

The Obvious Threat: Extreme Heat

The risk of severe burns is always present. Surfaces can remain dangerously hot long after the power is shut off, requiring appropriate personal protective equipment (PPE), such as thermal gloves and face shields.

A critical operational rule is to never open the furnace door at high temperatures (e.g., above 600°C). Doing so can cause a rapid, hazardous release of heat and potentially cause thermal shock to the furnace tube, leading to cracks or failure.

Similarly, never pour liquids or volatile solids into a hot furnace chamber. This can cause explosive vaporization and damage the heating elements and lining.

The Silent Threat: Atmosphere Control

Many processes require an inert atmosphere using gases like argon or nitrogen to prevent oxidation. These gases are colorless and odorless and work by displacing oxygen.

A leak in the gas supply lines or the furnace chamber can silently fill a poorly ventilated room, leading to asphyxiation with little to no warning. Proper ventilation and gas monitoring are non-negotiable.

The Hidden Force: Vacuum Operations

Using a furnace under vacuum introduces the risk of implosion. If the furnace tube has a structural defect or is damaged by thermal shock, the external atmospheric pressure can cause it to shatter inward violently.

This is especially dangerous with quartz or ceramic tubes, which can send sharp fragments flying. Always inspect vacuum-rated components for cracks or damage before each use.

Electrical and Chemical Hazards

The systems that power the furnace and the materials processed within it present their own distinct set of risks.

High-Voltage Systems

Electric furnaces operate on high-power electrical systems, creating a significant risk of electrical shock or electrocution. All maintenance and inspection should be performed only after the equipment is properly locked out and tagged out.

Ensuring the furnace is properly grounded and that all electrical enclosures are secure is fundamental to safe operation.

Thermal Runaway and Combustion

The furnace's temperature must never exceed its rated maximum. Doing so can damage the heating elements and insulation, creating a fire hazard and leading to catastrophic equipment failure.

This is often caused by a faulty temperature controller or thermocouple. Thermal runaway, where the temperature increases uncontrollably, can lead to a fire.

Furthermore, placing combustible or reactive materials inside the furnace can cause a fire or explosion. Always verify the thermal properties of any material before processing it.

Understanding the Trade-offs

The precision and control offered by a horizontal furnace come at the cost of increased operational complexity and risk. Acknowledging this trade-off is key to building a true safety culture.

The Cost of Advanced Control

The ability to control atmosphere and achieve precise temperatures is what makes these furnaces valuable. However, these systems (gas lines, vacuum pumps, high-power controllers) are also the primary sources of risk.

Treating the furnace like a simple oven is a common and dangerous mistake. Each specialized function adds a layer of responsibility for monitoring and maintenance.

The Need for Proactive Maintenance

A furnace's safety is only as good as its condition. A degraded door seal can leak inert gas, a failing thermocouple can cause thermal runaway, and a cracked tube can lead to implosion.

Routine maintenance is not an operational chore; it is a critical safety function. Regular calibration of temperature sensors, inspection of heating elements, and cleaning of the chamber prevent accidents before they happen.

Making the Right Choice for Your Goal

To ensure safety, your focus must align with your role. Use these points to guide your actions.

- If your primary focus is daily operation: Prioritize strict adherence to pre-operation checklists, PPE usage, and documented cooldown procedures before opening the furnace.

- If your primary focus is lab management or safety oversight: Implement and enforce a mandatory schedule for operator training, recertification, and proactive equipment maintenance.

- If your primary focus is material processing: Always verify material compatibility with the process temperature and atmosphere, and never exceed the furnace's maximum rated temperature.

Ultimately, safety in high-temperature work is not a single action but a continuous culture of awareness and discipline.

Summary Table:

| Risk Category | Key Hazards | Mitigation Strategies |

|---|---|---|

| Thermal & Environmental | Severe burns, thermal shock, asphyxiation, implosion | Use PPE, avoid opening door at high temps, ensure ventilation, inspect tubes |

| Electrical & Chemical | Electrical shock, thermal runaway, fire/explosion | Lockout/tagout systems, verify material compatibility, regular maintenance |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, minimizing risks and maximizing performance. Contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety