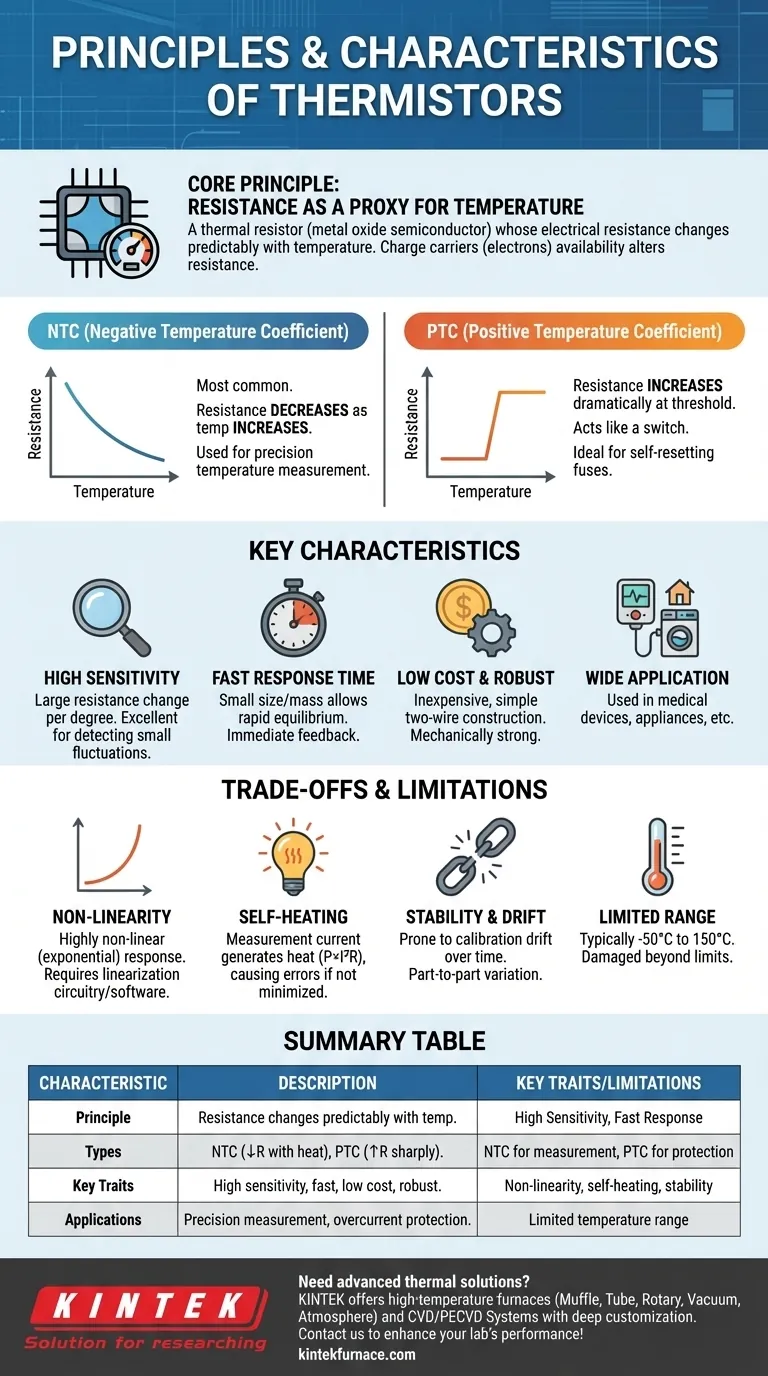

At its core, a thermistor is a simple thermal resistor. It is a type of sensor crafted from a metal oxide semiconductor whose electrical resistance changes in a predictable, pronounced way with temperature. This direct relationship allows a simple resistance measurement to be used as a proxy for a temperature reading.

While offering exceptional sensitivity and low cost, the thermistor's value is defined by a critical trade-off. Its highly non-linear response and potential for instability require careful engineering to unlock its precision.

The Core Principle: Resistance as a Proxy for Temperature

The operation of a thermistor is based on the fundamental properties of its semiconductor material. Unlike standard resistors, which are designed to have a stable resistance across a temperature range, thermistors are designed to do the exact opposite.

How a Thermistor Works

A thermistor's resistance is dependent on the number of available charge carriers (electrons) within its semiconductor material. As temperature changes, it alters the energy level of these electrons, dramatically increasing or decreasing the number available to conduct current, thus changing the material's overall resistance.

The Critical Distinction: NTC vs. PTC

Thermistors are divided into two fundamental types based on how their resistance responds to heat.

Negative Temperature Coefficient (NTC) thermistors are the most common type. Their resistance decreases as temperature increases. They are primarily used for precision temperature measurement.

Positive Temperature Coefficient (PTC) thermistors behave differently. Their resistance increases dramatically once they pass a specific temperature threshold. This switch-like behavior makes them ideal for use as self-resetting fuses in overcurrent and over-temperature protection circuits.

Key Characteristics of Thermistors

Understanding the primary attributes of thermistors shows why they are so widely used in specific applications, from medical devices to home appliances.

High Sensitivity (The Primary Advantage)

A thermistor exhibits a much larger change in resistance per degree of temperature change compared to other sensors like RTDs. This high sensitivity makes them excellent for detecting very small temperature fluctuations with precision.

Fast Response Time

Due to their typically small size and mass, thermistors can respond very quickly to changes in temperature. They reach thermal equilibrium with their environment rapidly, which is critical in applications requiring immediate feedback.

Low Cost and Mechanical Robustness

Thermistors are manufactured from common, inexpensive metal oxides. Their simple, two-wire construction makes them cheap to mass-produce, mechanically robust, and easy to integrate into a wide variety of designs.

Understanding the Trade-offs and Limitations

The high sensitivity and low cost of thermistors come with significant engineering challenges that must be managed for a successful design. Ignoring these trade-offs is a common source of measurement error.

The Challenge of Non-Linearity

The resistance-temperature relationship of an NTC thermistor is highly non-linear (exponential). This means a one-degree change at 0°C results in a different resistance change than a one-degree change at 50°C. This requires additional circuitry or software, such as lookup tables or the Steinhart-Hart equation, to convert the resistance reading into an accurate linear temperature value.

The Problem of Self-Heating

To measure resistance, you must pass a small current through the thermistor. This current itself generates a tiny amount of heat (P = I²R), which can raise the thermistor's temperature slightly above the ambient temperature you are trying to measure. This self-heating effect can introduce significant errors if not minimized by using the lowest possible measurement current.

Stability and Interchangeability

Thermistors can be prone to calibration drift, meaning their resistance characteristics can change over time, especially after exposure to high temperatures. Furthermore, there can be significant part-to-part variation in their resistance curves, making it difficult to swap one thermistor for another without recalibration.

Limited Operating Range

While highly sensitive within their designed range (typically -50°C to 150°C), thermistors are not suitable for the extreme high or low temperatures that sensors like thermocouples can handle. Their material can be permanently damaged beyond these limits.

Making the Right Choice for Your Application

Selecting the right temperature sensor requires aligning its characteristics with your primary goal.

- If your primary focus is cost-effective, high-sensitivity measurement in a specific range: A Negative Temperature Coefficient (NTC) thermistor is excellent, provided you implement linearization and account for self-heating.

- If your primary focus is simple, self-resetting circuit protection: A Positive Temperature Coefficient (PTC) thermistor acts as an effective solid-state fuse for overcurrent or over-temperature events.

- If your primary focus is high precision, stability, and interchangeability over a wide temperature range: A platinum Resistance Temperature Detector (RTD) or a calibrated thermocouple is often a more suitable choice despite the higher cost.

Understanding these core principles and trade-offs empowers you to select a thermistor not just for what it is, but for what it can achieve within your specific design constraints.

Summary Table:

| Characteristic | Description |

|---|---|

| Principle | Resistance changes predictably with temperature in metal oxide semiconductors. |

| Types | NTC (resistance decreases with heat), PTC (resistance increases sharply at threshold). |

| Key Traits | High sensitivity, fast response time, low cost, mechanical robustness. |

| Limitations | Non-linearity, self-heating, stability issues, limited temperature range. |

| Applications | Precision temperature measurement, overcurrent/over-temperature protection. |

Need advanced thermal solutions for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique experimental needs. Contact us today to enhance your laboratory's efficiency and performance!

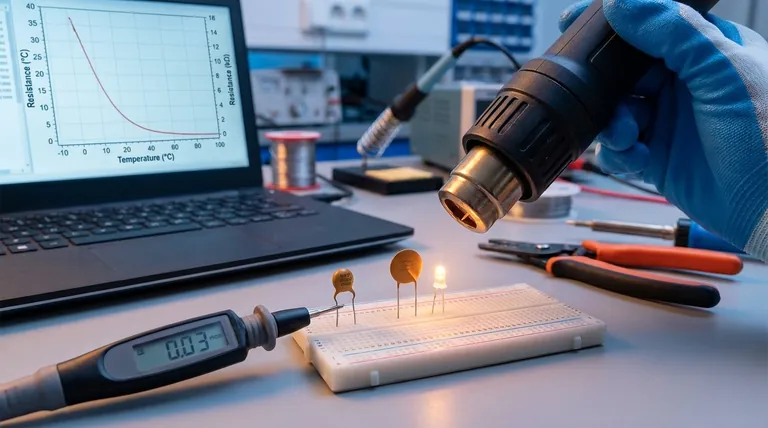

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability