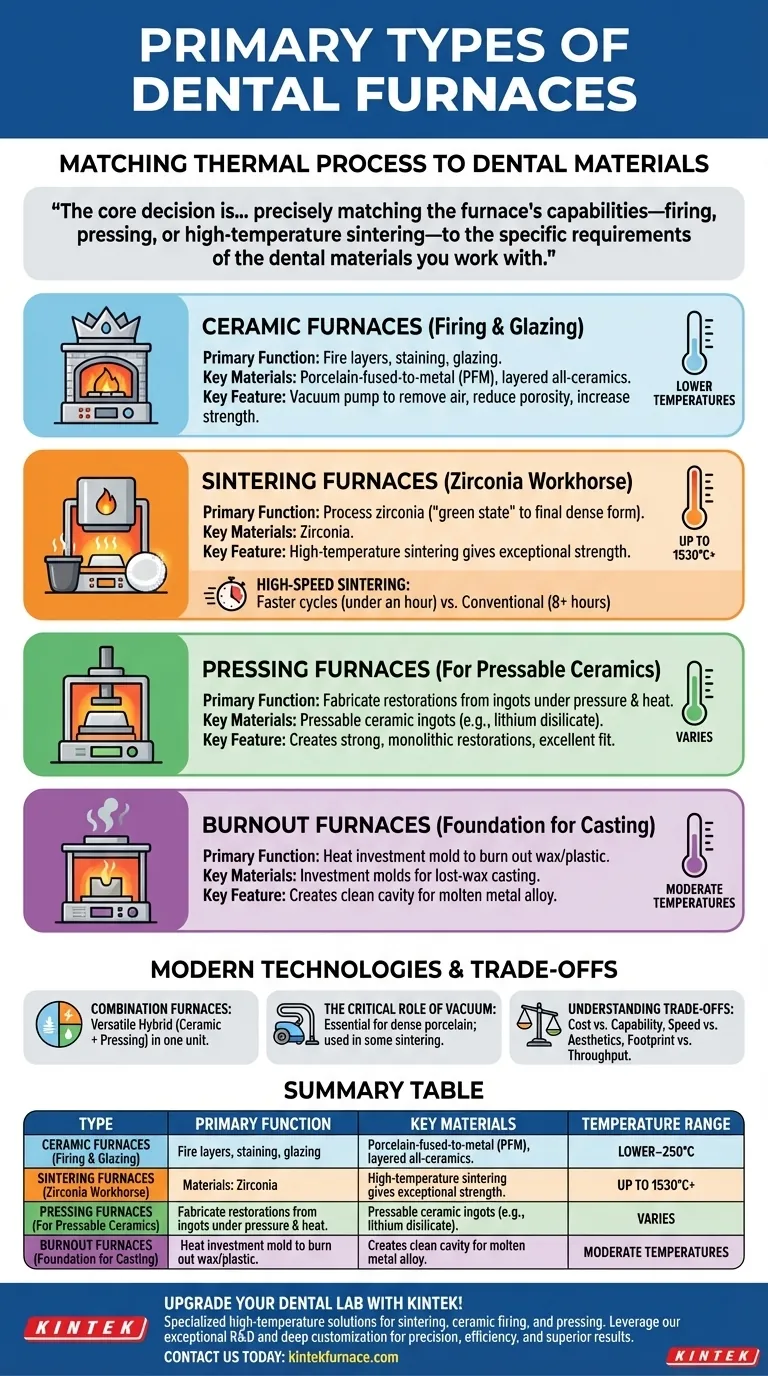

The primary types of dental furnaces are categorized by their specific thermal process and the materials they are designed to handle. The main functional categories are ceramic (or firing) furnaces, sintering furnaces, pressing furnaces, and burnout furnaces, with some modern units combining multiple functions. Each type serves a distinct purpose in the creation of dental restorations.

The core decision is not about finding the single "best" furnace, but about precisely matching the furnace's capabilities—firing, pressing, or high-temperature sintering—to the specific requirements of the dental materials you work with.

The Functional Categories: Matching Furnace to Material

A dental furnace is not a one-size-fits-all device. Its design is fundamentally tied to the material it must process, whether that involves layering porcelain, hardening zirconia, or pressing a ceramic ingot.

Ceramic Furnaces: For Firing and Glazing

Ceramic furnaces are the traditional workhorses for porcelain-fused-to-metal (PFM) and layered all-ceramic restorations. Their primary job is to fire layers of porcelain, as well as perform final staining and glazing.

These furnaces operate at lower temperatures compared to sintering units. Most high-quality ceramic furnaces incorporate a vacuum pump to remove air during the firing cycle, which reduces porosity and increases the final strength and translucency of the porcelain.

Sintering Furnaces: The Zirconia Workhorse

Sintering furnaces are built for one primary task: processing zirconia. They operate at extremely high temperatures (often up to 1530°C or higher) to transform pre-sintered, chalky zirconia ("green state") into its final, dense, and durable form.

This high-temperature process, known as sintering, is what gives zirconia its exceptional strength. A ceramic furnace cannot reach the temperatures required to properly sinter zirconia.

Pressing Furnaces: For Pressable Ceramics

Pressing furnaces are designed to fabricate restorations from pressable ceramic ingots, such as lithium disilicate. The process involves melting the ceramic ingot under pressure and heat, forcing it into a void created by a wax burnout.

This method is distinct from layering porcelain or sintering zirconia. It is used to create strong, monolithic restorations like veneers, inlays, and crowns with excellent fit and aesthetics.

Burnout Furnaces: The Foundation for Casting

Burnout furnaces are used in the traditional lost-wax casting technique, primarily for creating metal frameworks for crowns and bridges. Their sole function is to heat a refractory investment mold to completely burn out the wax or plastic pattern inside.

This creates a clean, empty cavity into which molten metal alloy is cast. While distinct from the furnaces that process final ceramics, they are a critical step in the PFM workflow.

Key Technologies That Define Modern Furnaces

Beyond the core function, several technological advancements define the capabilities and efficiency of modern dental furnaces. These are often features rather than distinct furnace "types."

Combination Furnaces: The Versatile Hybrid

To save space and cost, many manufacturers offer combination furnaces. The most common type combines the functions of a ceramic furnace and a pressing furnace into a single unit.

These hybrids are extremely popular in labs that work with both layered porcelain and pressable ceramics, offering versatility without the need for two separate machines.

The Rise of High-Speed Sintering

Within the sintering category, speed has become a major differentiator. Conventional sintering furnaces have long, slow cycles (often 8+ hours) that produce excellent results.

Newer high-speed or "speed" sintering furnaces can complete a cycle in a fraction of that time, sometimes under an hour. This dramatic increase in throughput comes from advanced heating elements or, in some cases, microwave technology.

The Critical Role of Vacuum

A vacuum is not a type of furnace, but a crucial feature. In ceramic furnaces, a vacuum cycle is essential for creating dense, bubble-free porcelain. In some advanced sintering furnaces, a vacuum may be used to achieve specific material properties.

Understanding whether a furnace uses a vacuum, and for what purpose, is key to evaluating its capability for high-end aesthetic work.

Understanding the Trade-offs

Choosing a furnace involves balancing cost, speed, and quality. No single unit is perfect for every application.

Cost vs. Capability

Dedicated, high-temperature sintering furnaces represent a significant capital investment. A simple burnout furnace is on the opposite end of the cost spectrum. Combination furnaces provide a middle ground, offering more capabilities than a basic ceramic furnace but for less than the cost of two separate, dedicated units.

Speed vs. Final Aesthetics

This trade-off is most relevant for zirconia sintering. While high-speed sintering offers incredible efficiency, some dental technicians argue that the slower, conventional cycles can yield slightly higher translucency and better aesthetic outcomes. The choice depends on balancing the need for rapid turnaround with the highest possible aesthetic demands.

Footprint vs. Throughput

For a busy lab, workflow is paramount. Do you invest in one large-capacity furnace or multiple smaller, faster units? A large conventional furnace can process many units overnight, while several speed-sintering furnaces can enable a same-day restoration workflow. The decision hinges on your lab's specific business model.

Making the Right Choice for Your Workflow

Your material choices directly dictate your furnace requirements. Use this guide to determine the best fit for your lab or clinic.

- If your primary focus is PFM and layered ceramics: A dedicated ceramic furnace with a quality vacuum pump is your essential tool.

- If your primary focus is zirconia restorations: A high-temperature sintering furnace is non-negotiable; consider a high-speed model for improved throughput.

- If your primary focus is pressable restorations (e.g., lithium disilicate): You need a furnace with pressing capabilities, either a dedicated unit or a combination furnace.

- If you are a versatile lab with limited space: A combination press-and-fire furnace offers the best balance of capability and operational efficiency.

Ultimately, understanding the material dictates the technology, ensuring predictable and high-quality results for every restoration you create.

Summary Table:

| Type | Primary Function | Key Materials | Temperature Range |

|---|---|---|---|

| Ceramic Furnace | Firing and glazing | Porcelain, PFM | Lower temperatures |

| Sintering Furnace | High-temperature sintering | Zirconia | Up to 1530°C+ |

| Pressing Furnace | Pressing ceramics | Lithium disilicate ingots | Varies |

| Burnout Furnace | Wax burnout for casting | Investment molds | Moderate temperatures |

Upgrade your dental lab with KINTEK's advanced furnace solutions! We specialize in high-temperature furnaces tailored for dental applications, including sintering, ceramic firing, and pressing. Leveraging exceptional R&D and in-house manufacturing, KINTEK offers products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique experimental needs. Whether you're processing zirconia, porcelain, or pressable ceramics, our solutions ensure precision, efficiency, and superior results. Contact us today to discuss how we can enhance your workflow and deliver reliable performance for your dental restorations!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab