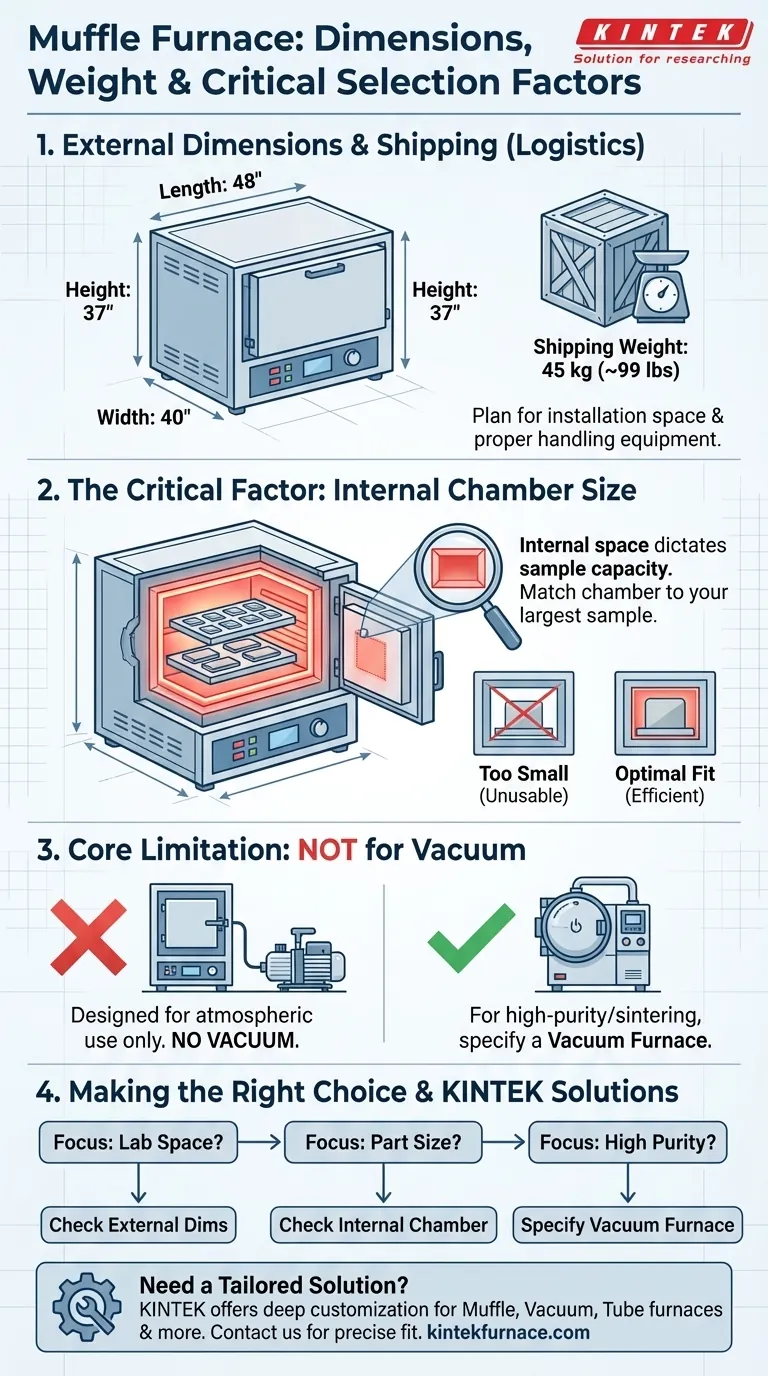

To be precise, the muffle furnace has external dimensions of 48 inches in length, 40 inches in width, and 37 inches in height. Its shipping weight is 45 kilograms.

While the external dimensions dictate the physical space required for installation, the internal chamber size is the critical factor that determines the furnace's suitability for your specific samples and applications.

Evaluating a Muffle Furnace Beyond its Footprint

When acquiring a muffle furnace, its physical size and weight are the first logistical hurdles. These specifications determine where it can be installed and how it will be transported. However, the true evaluation of the furnace's utility lies in understanding its internal capacity and operational limits.

External Dimensions and Installation

The overall size of the furnace dictates its placement in your lab or workshop.

Length: 48 inches Width: 40 inches Height: 37 inches

You must ensure adequate clearance around these dimensions for ventilation, user access, and maintenance.

Shipping and Handling

The shipping weight is a key logistical data point for receiving the equipment.

Shipping Weight: 45 kilograms (approximately 99 pounds)

This weight requires proper equipment and personnel for safe unloading and placement. The furnace is handled carefully during transit to preserve its condition.

The Critical Factor: Internal Chamber Dimensions

The most important specification for your work is not the furnace's outer shell, but the usable space inside it.

Matching Chamber to Sample Size

The internal chamber dimensions must accommodate your samples. A chamber that is too small will be unusable, while a chamber that is excessively large for small samples can be inefficient.

When evaluating a furnace, always request the internal chamber measurements. These should align directly with the maximum size of the objects you intend to heat treat.

Understanding the Trade-offs and Limitations

A muffle furnace is a powerful tool, but it is not universally applicable. Understanding its core limitations is crucial to avoid costly mistakes.

No-Go: Vacuum Applications

Muffle furnaces are designed to operate in a standard atmospheric environment. They are not suitable for any process requiring a vacuum.

The design of a muffle furnace cannot contain a vacuum. Attempting to do so is ineffective and unsafe.

When to Choose a Vacuum Furnace

For processes like sintering sensitive materials or heat treatments that must be free from atmospheric contamination, a vacuum furnace is required. This type of furnace is specifically designed to eliminate air and other gases from the chamber, creating a controlled, contamination-free environment.

Making the Right Choice for Your Goal

Selecting the correct furnace requires looking past the basic footprint and aligning the equipment's capabilities with your scientific or production needs.

- If your primary focus is fitting the furnace in your lab: Use the external dimensions (48" L x 40" W x 37" H) and weight (45 kg) to plan your space and logistics.

- If your primary focus is processing specific parts: You must obtain the internal chamber dimensions and ensure they are larger than your largest sample.

- If your primary focus is high-purity material processing: You must look beyond a muffle furnace and specify a vacuum furnace for your application.

Ultimately, a successful purchase depends on matching the furnace's internal capacity and operational environment to your specific application.

Summary Table:

| Specification | Value |

|---|---|

| External Length | 48 inches |

| External Width | 40 inches |

| External Height | 37 inches |

| Shipping Weight | 45 kilograms |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise fit for your experimental requirements. Contact us today to discuss how we can enhance your processes with reliable, custom furnace solutions!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites