At their core, vertical fluidized bed tube furnaces are highly versatile systems used across energy, chemical processing, and advanced materials manufacturing. Their primary industrial applications range from large-scale power generation and petroleum refining to the high-precision synthesis of semiconductors and nanomaterials, all unified by the need for exceptionally uniform heat treatment of granular or powdered solids.

The defining advantage of a vertical fluidized bed furnace is not its ability to reach high temperatures, but its capacity for superior heat and mass transfer. This uniform processing environment is what makes it indispensable for applications demanding precise control over reactions involving solid particles.

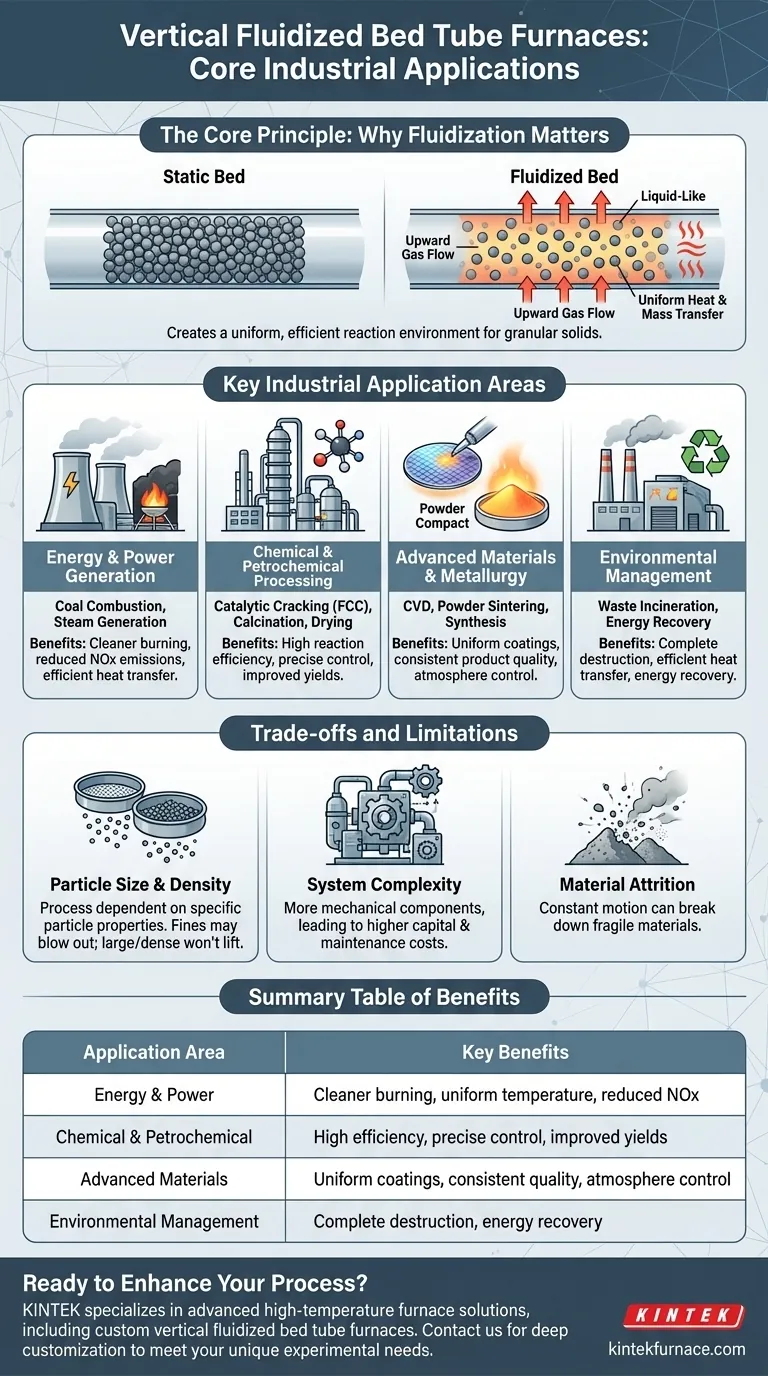

The Core Principle: Why Fluidization Matters

To understand the applications, you must first understand the "fluidized bed." This is the key technological principle that sets these furnaces apart.

Creating a "Liquid-Like" Solid

A fluidized bed is created when a flow of gas is passed upward through a bed of solid particles. At a specific velocity, the gas flow counteracts gravity, causing the particles to become suspended and move freely, behaving much like a boiling liquid.

Unmatched Temperature Uniformity

This constant motion ensures that heat is distributed almost instantaneously throughout the entire volume of material. This eliminates hot spots and cold spots, guaranteeing that every particle experiences the exact same thermal conditions.

Enhanced Reaction Efficiency

The "liquid-like" state maximizes the surface area contact between the solid particles and the processing gas. This, combined with uniform temperature, dramatically accelerates reaction rates and improves process efficiency and product consistency.

Key Industrial Application Areas

The unique characteristics of fluidization make these furnaces the ideal choice for several demanding industrial sectors.

Energy and Power Generation

In coal-fired power plants, fluidized bed combustors allow for the efficient and cleaner burning of various grades of coal. The uniform, lower-temperature combustion reduces the formation of harmful nitrogen oxides (NOx). They are also used for steam generation and heating thermal transfer fluids for other industrial processes.

Chemical and Petrochemical Processing

This is a major application area. In petroleum refining, fluidized bed catalytic cracking (FCC) is a cornerstone process used to break down large hydrocarbon molecules into more valuable gasoline and other products. The furnace's uniform temperature is critical for controlling the reaction and maximizing yield.

Other chemical processes include the calcination (high-temperature heating to cause decomposition) of minerals and the drying of granular raw materials where speed and uniformity are essential.

Advanced Materials and Metallurgy

This furnace type is fundamental to modern materials science. Applications include:

- Chemical Vapor Deposition (CVD): For creating thin films on semiconductor wafers or functional coatings on parts. The uniform temperature and gas distribution are vital for a consistent, high-quality coating.

- Powder Metallurgy and Sintering: For creating solid parts from metal or ceramic powders. The furnace provides the precise, uniform heat needed to bond the particles together without melting them.

- Synthesis and Annealing: For creating high-purity inorganic compounds or heat-treating materials to alter their crystal structure and properties. The vertical tube design allows for strict atmosphere control (e.g., vacuum or inert gas).

Environmental Management

Fluidized bed incinerators are highly effective for the combustion of solid waste, including municipal sludge and industrial byproducts. The intense mixing and efficient heat transfer ensure complete destruction of waste materials, often with the added benefit of energy recovery.

Understanding the Trade-offs and Limitations

While powerful, these furnaces are not a universal solution. Their specialized nature comes with specific constraints.

Particle Size and Density

The process is highly dependent on the physical properties of the solid material. Particles must be within a specific size and density range to fluidize properly. If they are too fine, they will be blown out of the furnace; if they are too large or dense, they will not lift.

System Complexity and Maintenance

A fluidized bed system is more mechanically complex than a simple static furnace. It requires robust gas distribution plates, powerful blowers, and often cyclone separators or filters to capture fine particles exiting with the gas, leading to higher capital and maintenance costs.

Material Attrition

The constant, vigorous motion of the particles can cause them to rub against each other and break down. This attrition can be a significant problem when processing fragile or abrasive materials, creating unwanted fine dust.

Making the Right Choice for Your Goal

Choosing a vertical fluidized bed furnace depends entirely on whether your process benefits from its unique heat and mass transfer characteristics.

- If your primary focus is bulk chemical conversion or combustion: The furnace's high efficiency in handling solid reactants, as seen in catalytic cracking or waste incineration, is its greatest strength.

- If your primary focus is high-purity material synthesis or coating (e.g., CVD): The exceptional temperature uniformity is non-negotiable for creating consistent, high-quality films and powders.

- If your primary focus is simple heat treatment of solid, non-particulate items: A standard batch furnace or a non-fluidized tube furnace may be a more cost-effective and simpler solution.

Ultimately, understanding the principle of fluidization is the key to leveraging this powerful technology for precise and efficient material processing.

Summary Table:

| Application Area | Key Uses | Benefits |

|---|---|---|

| Energy and Power Generation | Coal combustion, steam generation | Cleaner burning, uniform temperature, reduced NOx emissions |

| Chemical and Petrochemical Processing | Catalytic cracking, calcination, drying | High reaction efficiency, precise control, improved yields |

| Advanced Materials and Metallurgy | CVD, powder sintering, synthesis | Uniform coatings, consistent product quality, atmosphere control |

| Environmental Management | Waste incineration | Complete destruction, energy recovery, efficient heat transfer |

Ready to enhance your industrial processes with precise and efficient heat treatment? KINTEK specializes in advanced high-temperature furnace solutions, including custom vertical fluidized bed tube furnaces. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique experimental needs. Contact us today to discuss how we can optimize your energy, chemical, or materials applications—get in touch now!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the benefits of Tube Furnaces? Achieve Precision, Control, and Versatility in Thermal Processing

- What is the function of a double-zoned tube furnace in CVD of 2DP-F films? Unlock Precise Thin-Film Growth Control

- How does a dual-zone tube furnace facilitate the synthesis of CrSBr single crystals? Master the CVT Process

- What role does a tube furnace play in the preparation of biochar-filled PVC composite precursors? Expert Synthesis Guide

- What is a laboratory tube furnace and how is it designed? Master Precise Heating for Your Lab

- What is the purpose of using high-purity quartz tubes and vacuum sealing for Cu13Se52Bi35 alloy preparation?

- How does a tube furnace ensure the modification quality during the synthesis of phenyl-modified carbon nitride (PhCN)?

- How does the use of a tube furnace enhance cellulose-amine materials? Unlock Superior Porosity & Surface Area