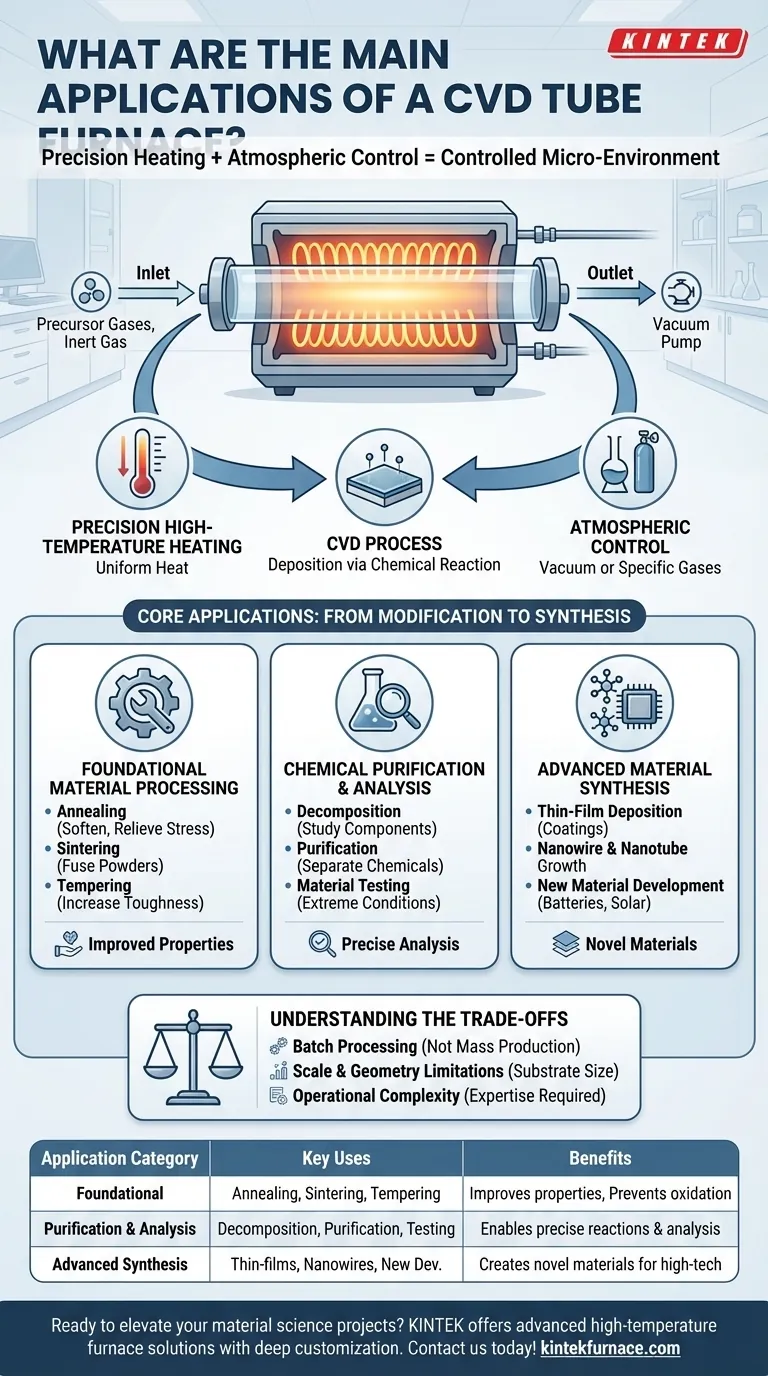

At its core, a Chemical Vapor Deposition (CVD) tube furnace is a high-precision instrument for creating and modifying advanced materials in a tightly controlled environment. Its primary applications range from fundamental material processing, like strengthening metals through annealing, to advanced synthesis, such as growing nanomaterials or depositing ultra-thin semiconductor films.

The true value of a CVD tube furnace is not just its ability to generate high temperatures, but its capacity to create a controlled micro-environment. By precisely managing both heat and atmosphere (vacuum or specific gases), it becomes a versatile platform for a vast array of material science applications.

How a CVD Furnace Enables Advanced Material Science

The furnace's versatility stems from its two fundamental capabilities: precise thermal management and atmospheric control. Understanding how these work together is key to understanding its applications.

Precision High-Temperature Heating

A tube furnace uses powerful heating coils wrapped around a cylindrical chamber, often made of quartz or alumina. This design, combined with high-grade insulation, ensures exceptional temperature uniformity across the entire processing area.

This consistent heat is critical for processes where even minor temperature variations can ruin the outcome, such as growing a perfectly uniform crystal or annealing a metal component without creating weak spots.

Atmospheric Control

The "tube" is a sealed chamber that can be connected to vacuum pumps and gas delivery systems. This allows an operator to first remove unwanted air and moisture by creating a vacuum.

Next, specific gases can be introduced into the chamber. This could be an inert gas like argon to prevent oxidation, or it could be a mixture of precursor gases that will react and form a new material.

The CVD Process Explained

The term Chemical Vapor Deposition (CVD) describes the furnace's most advanced function. In this process, volatile precursor gases are introduced into the hot chamber.

The high temperature provides the energy for these gases to react and "decompose," depositing a solid thin film onto a substrate (like a silicon wafer) placed inside the furnace. This is how many semiconductor layers and protective coatings are made.

Core Applications: From Modification to Synthesis

The combination of heat and atmospheric control unlocks three main categories of applications, each serving a different scientific or industrial goal.

Foundational Material Processing

This involves using heat to alter the properties of an existing material. The controlled atmosphere is typically used to prevent unwanted chemical reactions, like oxidation.

Applications include:

- Annealing: Softening materials and relieving internal stresses to improve ductility.

- Sintering: Fusing powders together to create a solid object (e.g., in ceramics or battery material production).

- Tempering: Increasing the toughness of metals like steel.

Chemical Purification and Analysis

In this context, the furnace acts as a small-scale chemical reactor. Heat is used to drive chemical reactions or physical changes for study or purification.

This is common in research institutes for:

- Decomposition: Breaking down a compound to study its components.

- Purification: Separating a desired chemical by heating a mixture to evaporate impurities.

- Material Testing: Observing how a material behaves or degrades under extreme heat.

Advanced Material Synthesis

This is where the "CVD" function shines, focusing on creating entirely new materials or structures with novel properties. These applications are foundational to nanotechnology and semiconductor manufacturing.

Key examples include:

- Thin-Film Deposition: Creating optical coatings, functional layers on semiconductor devices, and protective coatings.

- Nanowire and Nanotube Growth: Synthesizing one-dimensional nanostructures for electronics and composites.

- New Material Development: Researching and producing novel materials for batteries, solar cells, and other high-tech fields.

Understanding the Trade-offs

While incredibly versatile, a CVD tube furnace is a specialized tool with inherent limitations.

Batch Processing, Not Mass Production

These furnaces are designed for batch processing. A single substrate or a small group of components are loaded, processed, and then removed. They are not suitable for the continuous, high-throughput needs of mass manufacturing lines.

Scale and Geometry Limitations

The cylindrical shape and diameter of the tube restrict the size and shape of the substrate you can process. Large or irregularly shaped components cannot be accommodated.

Operational Complexity

Properly operating a CVD system requires significant expertise. It involves managing high-temperature systems, vacuum pumps, and potentially hazardous precursor gases, demanding a strong understanding of safety protocols and process parameters.

Making the Right Choice for Your Goal

To determine if a CVD tube furnace is the right tool, align its capabilities with your primary objective.

- If your primary focus is improving existing materials: The furnace's precise heat treatment and inert atmosphere capabilities make it ideal for annealing, sintering, and tempering.

- If your primary focus is creating new thin films or nanostructures: The full CVD functionality, combining heat with reactive precursor gases, is essential for this work.

- If your primary focus is chemical analysis or purification: The furnace provides a clean, controlled, and high-temperature reaction vessel perfect for lab-scale research and material testing.

Ultimately, the CVD tube furnace serves as a cornerstone of modern materials science, providing the controlled environment necessary to innovate at the atomic level.

Summary Table:

| Application Category | Key Uses | Benefits |

|---|---|---|

| Foundational Material Processing | Annealing, sintering, tempering | Improves material properties, prevents oxidation |

| Chemical Purification and Analysis | Decomposition, purification, material testing | Enables precise chemical reactions and analysis |

| Advanced Material Synthesis | Thin-film deposition, nanowire growth, new material development | Creates novel materials for high-tech applications |

Ready to elevate your material science projects with precision and control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including CVD Tube Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on material processing, synthesis, or purification, our expertise ensures optimal performance and reliability. Contact us today to discuss how we can support your innovations and drive your success!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab