In short, the primary advantages of electric rotary kilns are superior process control, higher thermal efficiency, and significantly lower maintenance requirements compared to their fuel-based counterparts. These factors lead to better product quality, a longer equipment lifespan, and improved environmental and operational safety.

The decision between an electric and a fuel-based rotary kiln is a choice between precision and brute force. While fuel offers raw heating power, electricity provides the granular control necessary for high-value materials, operational predictability, and long-term cost savings.

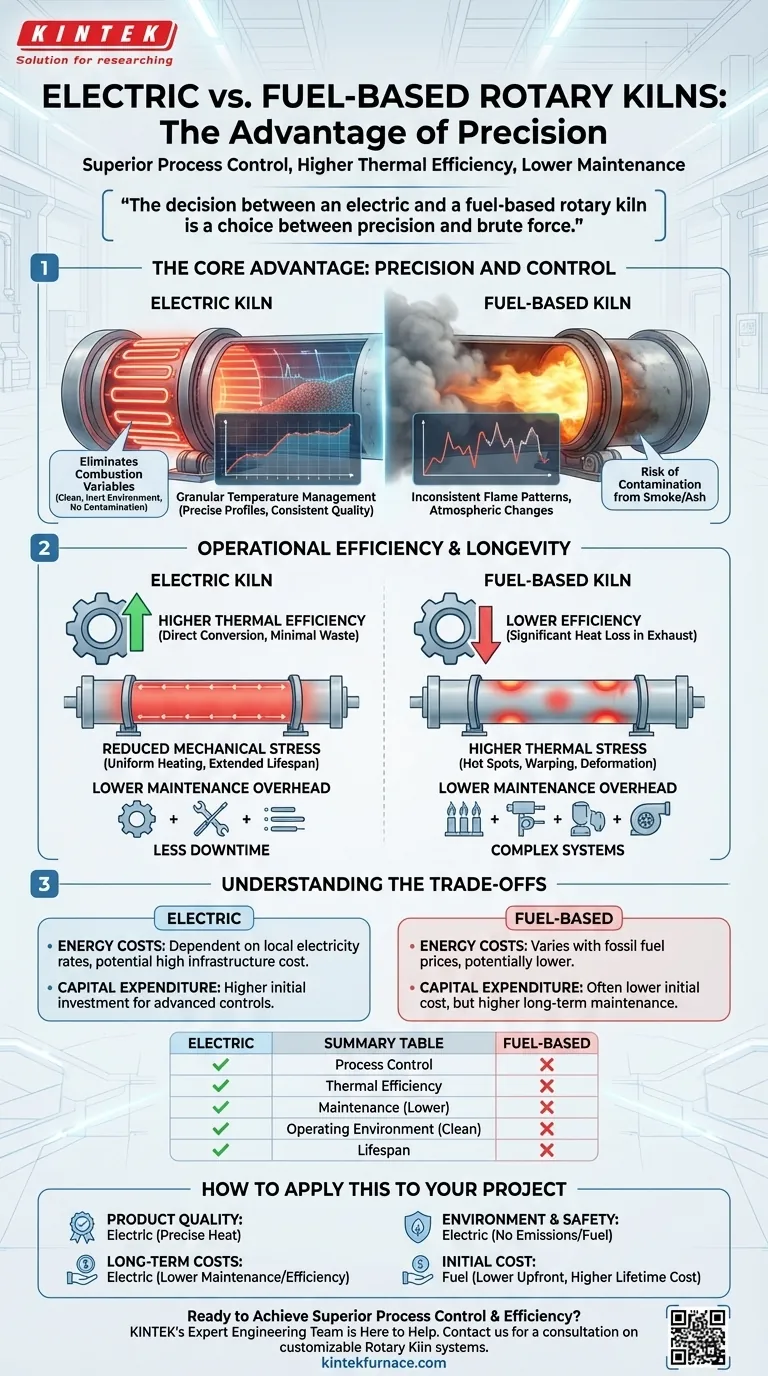

The Core Advantage: Precision and Control

The most significant differentiator for electric kilns is the ability to manage the heating process with exceptional accuracy. This control has direct impacts on product outcomes and process reliability.

Granular Temperature Management

Electric heating elements, governed by modern control systems, allow you to program and execute precise temperature profiles. This means you can control the ramp-up speed, soaking time, and cool-down rate with pinpoint accuracy.

This level of control is critical for materials sensitive to thermal shock or those requiring specific crystalline structures, resulting in consistently higher-quality, on-spec products.

Eliminating Combustion Variables

Fuel-based kilns introduce variables inherent to combustion. Factors like inconsistent flame patterns, atmospheric changes within the kiln from exhaust gases, and direct contamination from smoke or ash can negatively affect the final product.

Electric kilns provide a clean, inert heating environment, free from the byproducts of combustion. This purity is essential for applications in specialty chemicals, foods, and pharmaceuticals.

Operational Efficiency and Longevity

Beyond process control, electric kilns offer tangible benefits in day-to-day operation and equipment lifespan.

Higher Thermal Efficiency

Electric kilns convert electrical energy directly into radiant heat with very high efficiency. There is minimal energy wasted in exhaust gases, as is the case with fuel combustion, where a significant amount of heat is lost up the stack.

This means more of the energy you pay for is applied directly to your product, reducing overall consumption for a given process.

Reduced Mechanical Stress

The intense, localized heat of a fuel flame can create hot spots on the kiln shell, leading to thermal stress, warping, and eventual tube deformation. This is a primary driver of high maintenance costs in fuel-fired systems.

Electric heating is far more uniform, distributing thermal energy evenly. This gentle, controlled heating significantly reduces mechanical stress, extending the service life of the kiln tube and other critical components.

Lower Maintenance Overhead

Because they eliminate burners, fuel lines, blowers, and complex exhaust systems, electric kilns have fewer moving parts and points of failure.

This simplified design translates directly into lower maintenance costs, less downtime, and simpler operational oversight.

Understanding the Trade-offs

While the advantages are compelling, an objective analysis requires acknowledging the potential limitations of electric kilns.

Energy Costs and Infrastructure

The primary consideration is the local cost of electricity versus fossil fuels. In regions where electricity is expensive, the operational cost advantage can diminish or even reverse.

Furthermore, large electric kilns require substantial electrical infrastructure, which may necessitate costly upgrades to a facility's power supply.

Initial Capital Expenditure

The sophisticated control systems and heating element technology can sometimes result in a higher upfront purchase price for an electric rotary kiln compared to a simpler, fuel-fired equivalent.

This higher initial investment must be weighed against the long-term savings from reduced maintenance and higher efficiency.

How to Apply This to Your Project

Your choice should be dictated by your specific operational priorities and economic realities.

- If your primary focus is product quality and consistency: The precise, clean heat of an electric kiln is the superior choice.

- If your primary focus is minimizing long-term operational costs: An electric kiln is often the winner due to lower maintenance and higher efficiency, provided local electricity rates are competitive.

- If your primary focus is environmental compliance and workplace safety: An electric kiln is the clear leader, with no on-site emissions and the elimination of combustible fuel handling.

- If your primary focus is the lowest possible initial capital cost: A traditional fuel-based kiln may appear cheaper upfront, but this requires a thorough analysis of its higher lifetime maintenance and energy costs.

Ultimately, choosing an electric rotary kiln is an investment in process control, reliability, and operational cleanliness.

Summary Table:

| Feature | Electric Rotary Kiln | Fuel-Based Rotary Kiln |

|---|---|---|

| Process Control | Superior, precise temperature profiles | Lower, affected by combustion variables |

| Thermal Efficiency | Higher, direct energy conversion | Lower, significant heat loss in exhaust |

| Maintenance | Lower, fewer mechanical parts | Higher, due to burners and thermal stress |

| Operating Environment | Clean, inert, no combustion byproducts | Risk of contamination from smoke/ash |

| Lifespan | Longer, due to uniform heating | Shorter, due to thermal stress and hot spots |

Ready to Achieve Superior Process Control and Efficiency?

Choosing the right rotary kiln is critical for your product quality and operational costs. The advantages of an electric rotary kiln—precision, cleanliness, and long-term savings—are clear for high-value materials and demanding applications.

KINTEK's expert engineering team is here to help you make the right choice. Backed by expert R&D and manufacturing, KINTEK offers a range of high-temperature processing solutions, including customizable Rotary Kiln systems, designed for your unique material and production needs.

Contact our experts today for a consultation. Let's discuss how an electric rotary kiln from KINTEK can enhance your process reliability, improve your product quality, and reduce your total cost of ownership.

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity