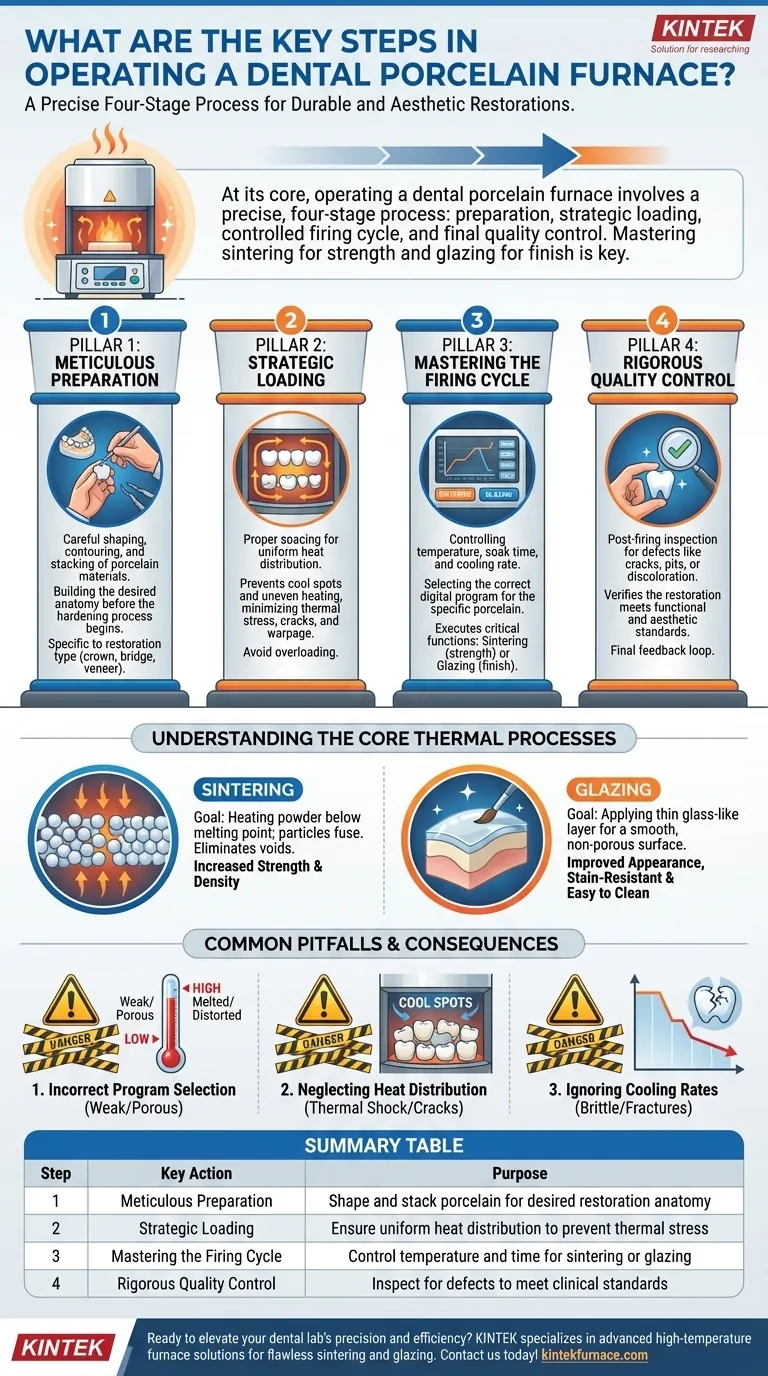

At its core, operating a dental porcelain furnace involves a precise, four-stage process: preparation of the material, strategic loading into the chamber, executing a controlled firing cycle, and performing final quality control. These steps ensure the raw porcelain is correctly transformed into a durable and aesthetically pleasing dental restoration that meets exacting clinical standards.

The key to successful furnace operation is not simply following steps, but understanding that you are controlling a sophisticated material transformation. Mastering the principles of sintering for strength and glazing for finish is what separates an acceptable result from an exceptional one.

The Four Pillars of Furnace Operation

Achieving a flawless restoration requires discipline and attention to detail at every stage. Each step builds upon the last, and a mistake in an early phase will invariably compromise the final product.

Step 1: Meticulous Preparation

Before the furnace is ever turned on, the foundation for success is laid. This involves the careful shaping, contouring, and stacking of the porcelain materials.

This work is done according to the specific requirements of the restoration, whether it's a crown, bridge, or veneer. The goal is to build the desired anatomy before the hardening process begins.

Step 2: Strategic Loading

How restorations are placed in the heating chamber is critical. They must be arranged with proper spacing to ensure uniform heat distribution.

If pieces are too close, they can create cool spots, preventing heat from reaching all surfaces evenly. This uneven heating introduces thermal stress, which can lead to cracks, warpage, or an incomplete firing process.

Step 3: Mastering the Firing Cycle

This is the heart of the operation, where the material is transformed. A firing cycle consists of precisely controlling temperature, the duration it's held (soak time), and the rate of cooling.

Modern furnaces use digital programs to automate this, but the technician must select the correct program based on the specific porcelain being used. This cycle executes one or more critical functions like sintering, glazing, or layering.

Step 4: Rigorous Quality Control

After the furnace has cooled and the restoration is removed, it must be inspected. This final check ensures the piece is free from defects like cracks, pits, or discoloration.

Quality control verifies that the restoration meets all functional and aesthetic standards before it is sent for placement. It is the final feedback loop on the success of the entire process.

Understanding the Core Thermal Processes

Simply running a program is insufficient. A true professional understands what is happening to the material inside the chamber. The two most important processes are sintering and glazing.

The Goal of Sintering

Sintering is the process of heating porcelain powder to a high temperature, just below its melting point. At this temperature, the individual particles fuse together, bonding without liquefying.

This process eliminates the voids between particles, dramatically increasing the material's strength and density. This is what gives the final restoration its structural integrity.

The Goal of Glazing

Glazing involves applying a final, thin layer of glass-like porcelain and firing it to create a smooth, non-porous surface.

This not only improves the restoration's appearance but also makes it stain-resistant and easy to clean, which is critical for oral hygiene and biocompatibility. For multi-layered restorations, each layer may be fired separately to achieve optimal results.

Understanding the Trade-offs and Common Pitfalls

While modern furnaces offer incredible control, they are not immune to operator error or material mismatch. Understanding the variables is key to consistent success.

Pitfall 1: Incorrect Program Selection

Choosing a firing cycle with a temperature that is too low for the material will result in incomplete sintering, leaving the restoration weak and porous.

Conversely, a temperature that is too high can cause the porcelain to melt, lose its shape, and appear glassy or translucent, ruining the restoration. Always verify the manufacturer's recommended firing parameters for your specific porcelain.

Pitfall 2: Neglecting Heat Distribution

As mentioned, poor loading is a primary cause of failure. Overloading the chamber or placing items too close together will block uniform heating.

This is the most common source of thermal shock and cracking. Always allow adequate space around each unit for air and heat to circulate freely.

Pitfall 3: Ignoring Cooling Rates

The rate at which the restoration cools is just as important as the rate it heats. A cooling rate that is too rapid can introduce internal stresses, making the porcelain brittle and prone to fracture later on.

The furnace's programmed cooling cycle is designed to prevent this by letting the temperature drop in a slow, controlled manner.

Making the Right Choice for Your Goal

Your operational focus should align with the primary goal of each specific firing. Use the furnace's capabilities to achieve a predictable outcome.

- If your primary focus is strength and density: Master the sintering cycle by ensuring the correct peak temperature and soak time are used for your material to achieve full particle fusion.

- If your primary focus is aesthetics and biocompatibility: Perfect the glazing cycle to produce a smooth, lustrous, and non-porous surface that resists staining and plaque accumulation.

- If your primary focus is consistency and efficiency: Leverage the furnace's programmable memory and follow a strict loading protocol to ensure every restoration receives the exact same thermal treatment.

Ultimately, your command of the furnace is what allows you to precisely transform simple powder into a durable and lifelike work of functional art.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Meticulous Preparation | Shape and stack porcelain for desired restoration anatomy |

| 2 | Strategic Loading | Ensure uniform heat distribution to prevent thermal stress |

| 3 | Mastering the Firing Cycle | Control temperature and time for sintering or glazing |

| 4 | Rigorous Quality Control | Inspect for defects to meet clinical standards |

Ready to elevate your dental lab's precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions tailored for dental laboratories. Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization, ensure you achieve flawless sintering and glazing for durable, aesthetic restorations. Contact us today to discuss how our expertise can transform your workflow and deliver exceptional results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations