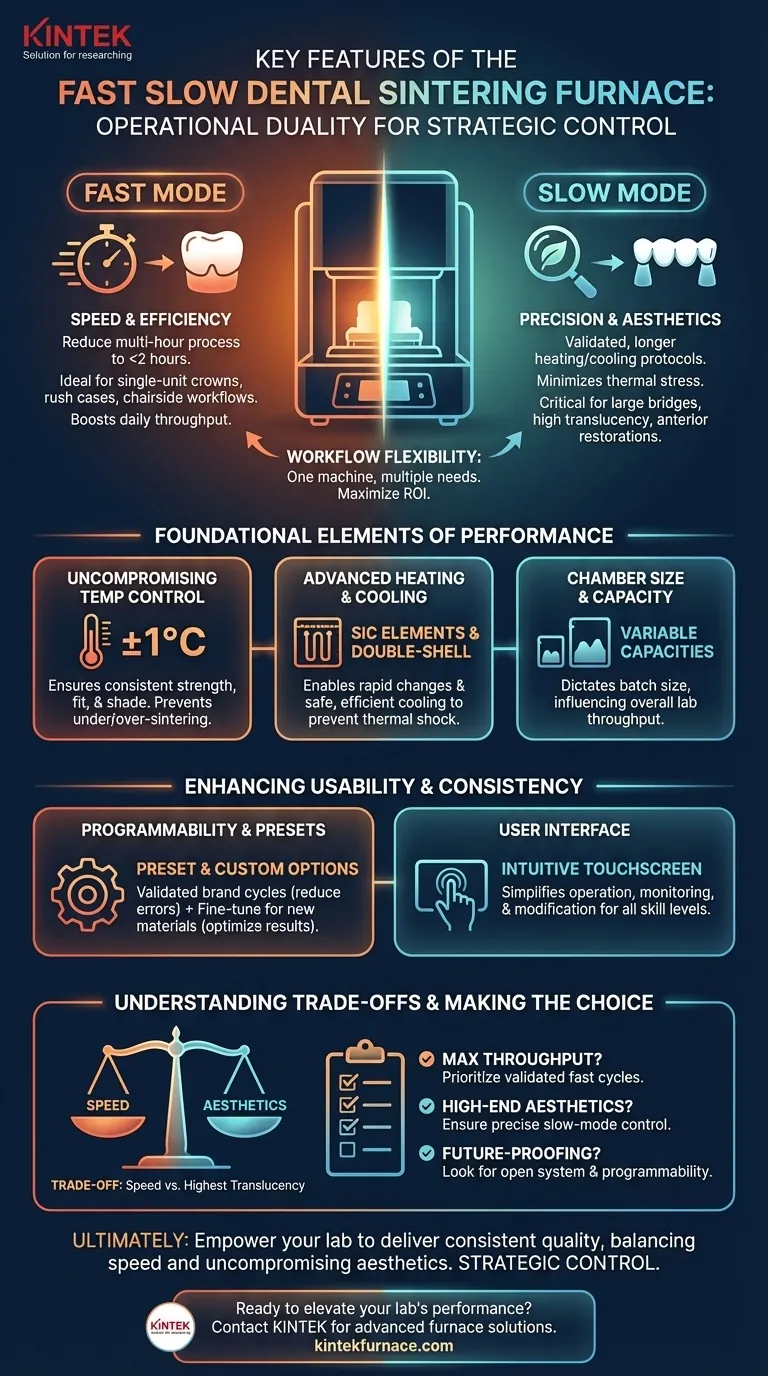

At its core, a Fast Slow Dental Sintering Furnace is defined by its operational duality. Its key features are the inclusion of both rapid and conventional sintering cycles, exceptionally precise temperature control often accurate to ±1°C, extensive programmability with preset and custom options, and a modern, user-friendly touchscreen interface.

The central value of a Fast Slow furnace is not just about having more features; it's about gaining strategic control. It empowers a dental lab to precisely balance the competing demands of production speed, material integrity, and final aesthetic quality for any given case.

The Core Feature: Dual Sintering Modes

The defining characteristic of this furnace category is its ability to offer two distinct sintering philosophies in one machine. This provides unparalleled flexibility to match the production process to the clinical need.

The "Fast" Mode: For Speed and Efficiency

Fast sintering cycles dramatically shorten the time required to process zirconia restorations, often reducing a multi-hour process to under two hours.

This mode is ideal for single-unit crowns, rush cases, or in-office "chairside" workflows where rapid turnaround is the primary driver. It significantly boosts a lab's daily throughput.

The "Slow" Mode: For Precision and Aesthetics

Conventional, or "slow," sintering follows the zirconia manufacturer's validated, longer heating and cooling protocols. This gentle process minimizes thermal stress on the material.

This mode is critical for larger, multi-unit bridges and for achieving the highest level of translucency and aesthetic outcomes, especially with anterior restorations.

The Impact on Workflow Flexibility

The ability to switch between modes means you don't have to dedicate equipment to a single workflow. A single furnace can handle an urgent single-unit crown in the morning and a complex, high-aesthetic bridge case in the afternoon, maximizing the return on your investment.

Foundational Elements of Performance

Beyond the dual modes, several hardware and software features are critical for achieving consistent, high-quality results. These elements are the foundation of the furnace's reliability.

Uncompromising Temperature Control

True precision comes from the furnace's ability to hit and hold target temperatures without fluctuation. A control accuracy of ±1°C is the benchmark.

This stability is non-negotiable for preventing under- or over-sintering, which directly impacts the restoration's final strength, fit, and shade.

Advanced Heating and Cooling Systems

The speed of the "fast" cycle is dependent on high-performance heating elements, typically made of silicon carbide (SiC), which can withstand rapid temperature changes.

An efficient cooling system and an insulated, double-shell structure are equally important. They allow the furnace to cool down quickly and safely, managing the "ramp rate" to prevent thermal shock to the restorations.

Chamber Size and Capacity

The physical size of the sintering chamber dictates your batch capacity. This directly influences how many units you can process at once, impacting overall lab throughput and efficiency.

Enhancing Usability and Consistency

Advanced features are only valuable if they are accessible and repeatable. Modern furnaces prioritize features that reduce the chance of human error and simplify daily operation.

Programmability and Preset Functions

Most furnaces come with preset programs for common zirconia brands and types. This ensures you are using a validated cycle right out of the box.

The ability to create and save custom programs gives experienced technicians the power to fine-tune cycles for new materials or specific aesthetic goals, ensuring consistent results every time.

The User Interface

A large, intuitive touchscreen interface has become standard. It simplifies program selection, monitoring, and modification, making the furnace accessible to technicians of all experience levels and reducing the learning curve.

Understanding the Trade-offs

While highly versatile, it is critical to understand the compromises inherent in using a dual-mode furnace.

Speed vs. Aesthetics

The primary trade-off is often between speed and the highest possible aesthetic outcome. While fast-sintered zirconia is clinically excellent, conventional, slower cycles generally yield superior translucency.

Material Compatibility

Not all zirconia materials are formulated or approved for rapid sintering cycles. Using a non-validated material in a fast cycle can compromise its structural integrity and long-term stability. Always verify manufacturer recommendations.

The Need for Program Optimization

While presets are a great starting point, achieving perfect results across different materials often requires testing and optimization. Relying on a "one size fits all" approach can lead to inconsistent outcomes.

Making the Right Choice for Your Lab

Selecting the right furnace requires aligning its capabilities with your lab's primary business goals.

- If your primary focus is maximum throughput and single-unit restorations: Prioritize a furnace with proven, reliable, and manufacturer-validated fast-sintering cycles.

- If your primary focus is high-end aesthetic, multi-unit bridgework: Ensure the slow-sintering mode offers precise temperature control and highly customizable ramp rates.

- If your primary focus is future-proofing and material flexibility: Look for an open system with extensive programmability and a strong track record of accommodating new zirconia types.

Ultimately, the right furnace empowers your lab to deliver consistent quality, whether the priority is speed or uncompromising aesthetics.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Dual Sintering Modes | Fast and slow cycles for flexibility | Matches process to clinical needs, boosts throughput and aesthetics |

| Precise Temperature Control | ±1°C accuracy | Ensures consistent strength, fit, and shade in restorations |

| Programmability | Preset and custom options | Reduces errors, supports material variety and optimization |

| User-Friendly Interface | Touchscreen controls | Simplifies operation for all technician levels |

| Advanced Heating/Cooling | SiC elements, double-shell structure | Enables rapid, safe sintering and cooling |

| Chamber Size | Variable capacities | Influences batch processing and lab efficiency |

Ready to elevate your dental lab's performance? KINTEK specializes in advanced high-temperature furnace solutions, leveraging exceptional R&D and in-house manufacturing. Our diverse product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you're focused on speed, aesthetics, or flexibility, we can help you achieve consistent, high-quality results. Contact us today to discuss how our Fast Slow Dental Sintering Furnace and other solutions can benefit your lab!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations