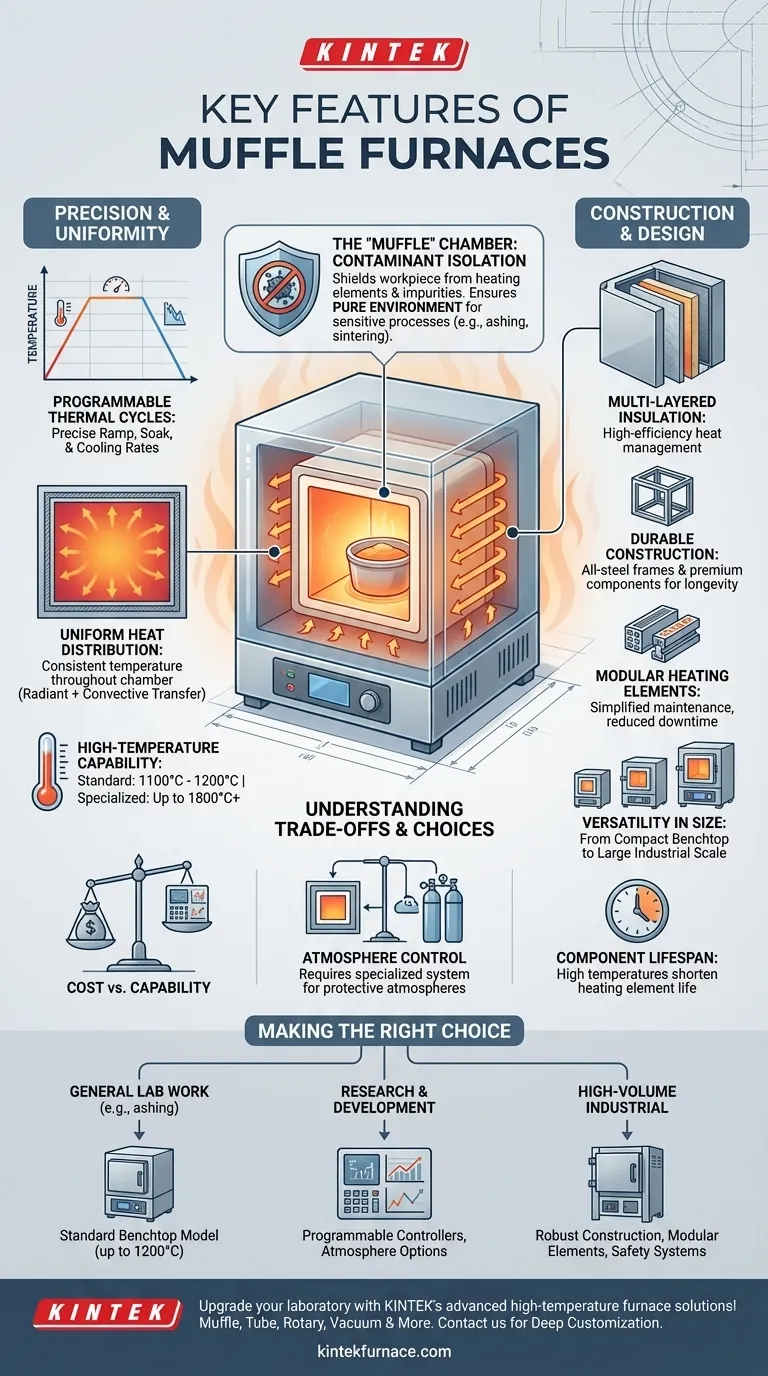

At their core, muffle furnaces are defined by a few key characteristics: their ability to achieve high, precisely controlled temperatures; their capacity for uniform heat distribution; and a design that isolates the heated material from contaminants. These instruments are not simply ovens; they are specialized tools for applications where temperature accuracy and material purity are paramount.

A muffle furnace's defining feature is the "muffle"—an inner chamber that shields the workpiece from direct contact with the heating elements and outside contaminants. This allows for clean, highly controlled thermal processing that is impossible to achieve in a standard oven.

The Defining Principle: The "Muffle"

The feature that gives the furnace its name is also its most important functional component. Understanding the muffle is key to understanding the instrument's purpose.

What is a Muffle?

A muffle is a sealed, high-temperature chamber that contains the material being processed. It acts as a physical barrier, or shield, between the material and the furnace's heating elements.

This chamber is constructed from heat-resistant materials like high-purity ceramics or specialized metal alloys that can withstand extreme thermal stress.

Why Contamination Control is Critical

The muffle's primary role is to ensure contaminant isolation. In an electric furnace, it prevents any outgassing or flaking from the heating elements from settling on the material.

This separation is essential for sensitive processes like ashing, sintering, or annealing, where even microscopic impurities can compromise the final result. It creates a pure environment for thermal processing.

Feature Deep Dive: Precision and Uniformity

Beyond isolation, a muffle furnace is an instrument of precision. Its features are geared towards delivering a specific thermal profile accurately and repeatedly.

High-Temperature Capability

Muffle furnaces are designed for high-temperature work, with standard models often reaching 1100°C to 1200°C. Specialized units, often utilizing advanced ceramic components, can achieve temperatures of 1800°C or higher.

Advanced Temperature Control

Modern furnaces use sophisticated controllers that allow for fully programmable thermal cycles. Users can set precise heating rates (ramps), holding times (soaks), and cooling rates.

This is made possible by high-quality thermocouples for accurate measurement and SCR power controllers that modulate energy delivery with extreme precision, avoiding temperature overshoots.

Uniform Heat Distribution

Consistent results depend on the entire workpiece experiencing the same temperature. Muffle furnaces are engineered for temperature uniformity throughout the chamber.

This is achieved through strategic placement of heating elements, the use of cubed chambers (which have better thermal dynamics), and a combination of radiant and convective heat transfer to ensure the entire internal volume is heated evenly.

Built for Extreme Environments: Construction and Design

The demanding conditions inside a muffle furnace necessitate a robust and durable design.

Heat-Resistant Materials

The entire furnace is built for heat management. This includes a multi-layered construction with high-efficiency insulation to keep the exterior cool and minimize energy loss.

Premium models often feature a double-shell construction with air gaps or fans to further reduce the external surface temperature, enhancing both safety and efficiency.

Structural Durability

Longevity is a key feature. Muffle furnaces are typically built with all-steel frames and premium components to withstand years of high-temperature cycling without degradation.

Features like modular heating elements are found in industrial models, simplifying maintenance and reducing downtime by allowing for quick replacement.

Versatility in Size

Muffle furnaces are not one-size-fits-all. They are available in a wide range of sizes, from small, compact benchtop units for academic labs to large, industrial-scale furnaces used in manufacturing.

Understanding the Trade-offs

Selecting a furnace requires balancing capability with cost and complexity.

Cost vs. Capability

Higher maximum temperatures, more sophisticated programmable controllers, and larger chamber volumes all increase the cost. A basic furnace for simple ashing is far less expensive than a programmable, high-temperature unit for materials research.

Atmosphere Control

A standard muffle provides excellent contaminant isolation from the furnace elements. However, it does not inherently control the atmosphere (e.g., oxygen, nitrogen, argon).

Achieving a specific protective atmosphere requires a furnace with sealed gas ports and a more complex control system, which represents a significant step up in cost and operational complexity.

Maintenance and Component Lifespan

Heating elements and thermocouples are consumable parts, especially when operated near their maximum temperature limits. Running a furnace consistently at its peak rating will shorten component life and increase long-term maintenance costs.

Making the Right Choice for Your Application

Your specific goal should dictate the features you prioritize.

- If your primary focus is general lab work like ashing or heat-treating: A standard benchtop model with precise temperature control up to 1200°C is typically sufficient.

- If your primary focus is materials research or process development: Prioritize models with fully programmable controllers for complex thermal profiles and consider units with options for atmosphere control.

- If your primary focus is high-volume industrial production: Look for robust construction, ease of maintenance (like modular heating elements), and advanced safety monitoring systems.

Understanding these core features empowers you to look beyond the spec sheet and select a furnace that truly meets your technical requirements.

Summary Table:

| Key Feature | Description |

|---|---|

| Contaminant Isolation | Muffle chamber shields materials from impurities, ensuring purity in processes like ashing and sintering. |

| High-Temperature Capability | Reaches 1100°C to 1800°C, ideal for demanding thermal applications. |

| Precision Temperature Control | Programmable cycles with SCR controllers for accurate heating, soaking, and cooling. |

| Uniform Heat Distribution | Even heating via strategic element placement and radiant/convective transfer for consistent results. |

| Durable Construction | Built with heat-resistant materials, all-steel frames, and modular elements for longevity. |

| Versatile Sizing | Available from benchtop to industrial scales to fit various lab and production needs. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency, accuracy, and purity in your processes. Contact us today to discuss how we can support your specific applications and drive your success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals