At its core, a horizontal tube furnace is a high-temperature heating device designed to create an exceptionally uniform thermal environment within a cylindrical chamber. Its key features are its horizontal orientation for easy sample handling, precise temperature and atmosphere control, and the ability to operate at temperatures often exceeding 1000°C, making it a versatile tool for laboratory research and industrial processing.

The defining feature of a horizontal tube furnace is not simply its ability to get hot, but its capacity to create a highly controlled and uniform environment. Its horizontal design prioritizes accessibility and consistent processing along the length of the sample.

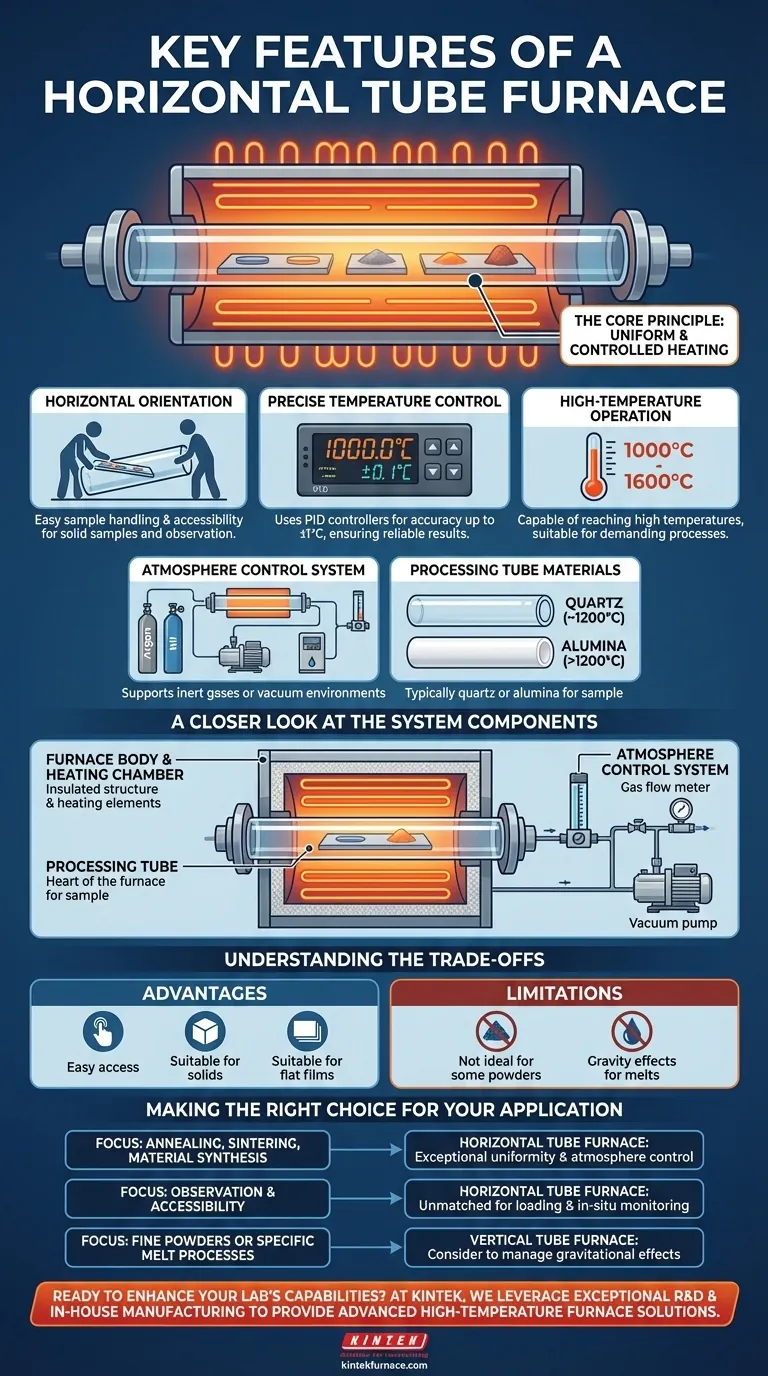

The Core Principle: Uniform and Controlled Heating

The primary function of a tube furnace is to provide a stable, predictable, and uniform heating zone. This is fundamental to achieving repeatable and reliable results in material processing and scientific experiments.

Achieving Temperature Uniformity

The tubular structure is the key to its performance. Heat is applied externally to the tube, creating a uniform hot zone along its central length.

This design minimizes temperature gradients, ensuring that the entire sample experiences the same thermal conditions, which is critical for processes like annealing, calcination, and crystal growth.

Precise Temperature Management

Modern tube furnaces are equipped with sophisticated controllers, typically using PID (Proportional-Integral-Derivative) algorithms.

These systems allow for precise setting and maintenance of the target temperature, often with an accuracy of ±1°C. This level of control is essential for experiments where thermal accuracy directly impacts the outcome.

High-Temperature Operation

Horizontal tube furnaces are built to handle extreme heat. Standard models regularly operate at temperatures between 1000°C and 1600°C.

The maximum temperature is determined by the heating elements and the material of the processing tube itself.

A Closer Look at the System Components

A tube furnace is more than just a heating chamber; it is a complete system where each part plays a critical role.

The Furnace Body and Heating Chamber

This is the main insulated structure that houses the heating elements. It features accessible end plugs that allow for easy insertion and removal of the processing tube.

The Processing Tube

This is the heart of the furnace where the sample is placed. It is typically made from quartz (for temperatures up to ~1200°C) or alumina (for higher temperatures).

The tube isolates the sample from the heating elements and contains the controlled atmosphere.

Atmosphere Control System

Many applications require processing in a specific gaseous environment, such as an inert gas (Argon, Nitrogen) or under a vacuum.

This is achieved with a system that includes:

- A gas flow meter or mass flow controller to regulate the gas supply.

- A vacuum pump to evacuate the air from the tube.

- Sealing flanges and valves to ensure the system is airtight.

Understanding the Trade-offs

The horizontal orientation offers distinct advantages but also has limitations to consider. Choosing the right furnace means understanding these trade-offs.

Advantage: Ease of Access and Observation

The horizontal layout is ideal for processes that require easy placement, manipulation, or direct observation of samples during the heating cycle. Loading and unloading samples, especially in batches, is simple and efficient.

Advantage: Suitability for Solid Samples

This design works exceptionally well for processing solid samples, thin films, or components that can be laid flat within the tube.

Limitation: Not Ideal for All Powders or Melts

For certain applications, gravity can be a factor. Fine powders may not remain evenly distributed, and some melting or liquid-phase processes are better handled in a vertical furnace, which uses gravity to its advantage.

Making the Right Choice for Your Application

Selecting the correct furnace configuration depends entirely on the requirements of your process.

- If your primary focus is annealing, sintering, or material synthesis: The exceptional temperature uniformity and atmosphere control of a horizontal tube furnace are your key benefits.

- If your primary focus is process observation and accessibility: The horizontal layout is unmatched for its ease of loading, unloading, and in-situ monitoring.

- If your primary focus is working with fine powders or specific melt processes: You may need to evaluate a vertical tube furnace as an alternative to better manage gravitational effects.

Ultimately, a horizontal tube furnace empowers you to take precise control over the thermal processing of your materials.

Summary Table:

| Feature | Description |

|---|---|

| Horizontal Orientation | Enables easy sample handling and accessibility for solid samples and observation. |

| Temperature Uniformity | Provides a stable hot zone with minimal gradients, ideal for annealing and synthesis. |

| Precise Temperature Control | Uses PID controllers for accuracy up to ±1°C, ensuring reliable experimental results. |

| High-Temperature Operation | Capable of reaching 1000°C to 1600°C, suitable for demanding thermal processes. |

| Atmosphere Control | Supports inert gases or vacuum environments with flow meters and pumps for specific applications. |

| Processing Tube Materials | Typically quartz (up to 1200°C) or alumina (higher temps) for sample isolation and durability. |

Ready to enhance your laboratory's capabilities with a custom horizontal tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse labs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how we can deliver precise, reliable heating solutions for your research and industrial processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability