At their core, low vacuum atmosphere furnaces are the workhorses for industrial heat treatment processes where absolute purity is not the primary goal. They excel in applications like annealing, brazing, and sintering for materials that are less sensitive to oxidation, such as stainless steel and certain ceramics. Their prevalence in industries like automotive manufacturing and tool making is due to their operational efficiency and cost-effectiveness.

The decision to use a low vacuum furnace is not about achieving a perfect vacuum, but about achieving the right level of atmospheric control for a specific material and process. It represents a deliberate trade-off, prioritizing speed and cost-efficiency for applications where moderate purity is sufficient.

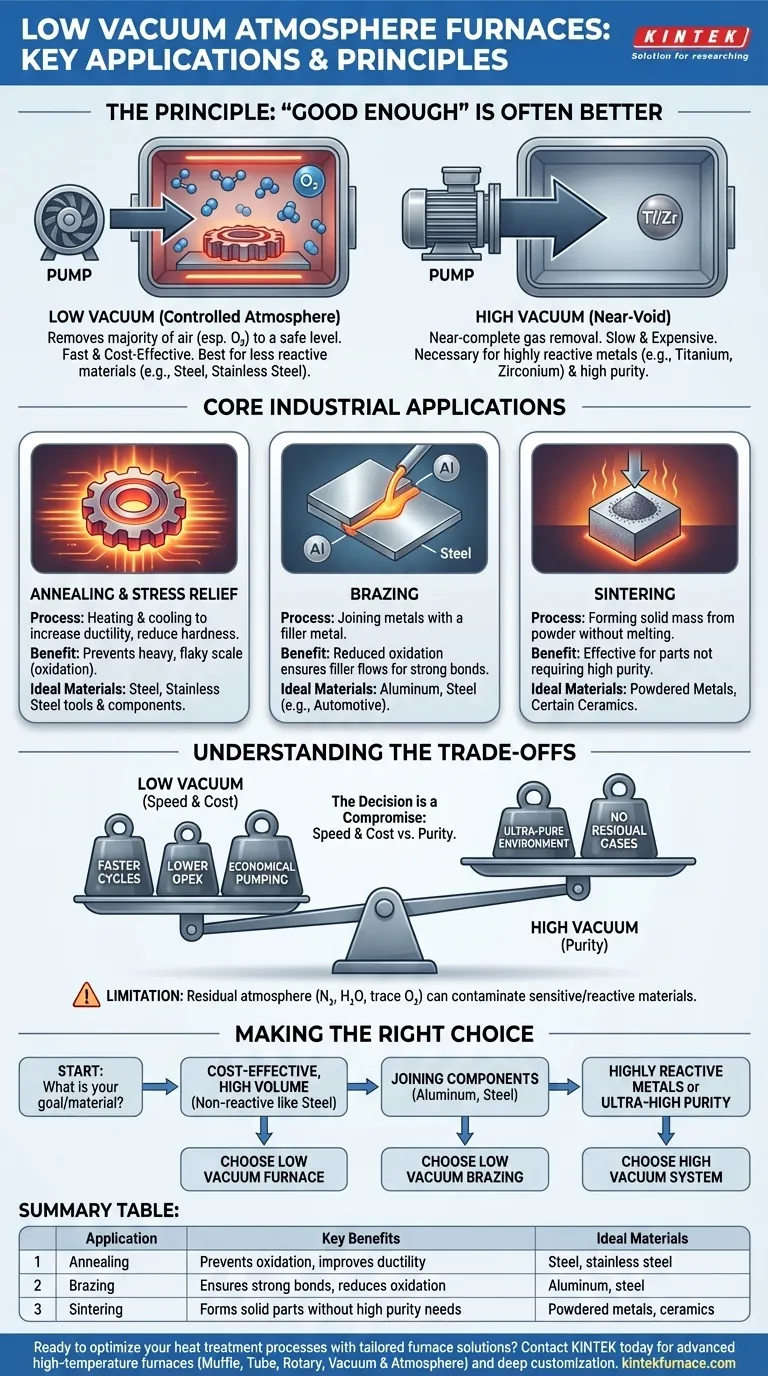

The Principle: Why "Good Enough" is Often Better

The value of a low vacuum furnace comes from understanding that removing every single gas molecule is often unnecessary and expensive. The goal is to reduce reactive gases to a level that does not harm the material being processed.

Controlling the Atmosphere, Not Eliminating It

Unlike high vacuum systems that aim for a near-void, low vacuum furnaces simply "pump down" the chamber to remove the majority of the ambient air, particularly oxygen. This creates a controlled, low-pressure environment that is adequate for many thermal processes.

Ideal for Less Reactive Materials

These furnaces are best suited for materials that have a natural resistance to oxidation or where minor surface interaction is acceptable. Metals like steel and stainless steel are prime examples, as they are not as reactive as materials like titanium or zirconium, which demand high vacuum.

The Cost-to-Purity Balance

The primary driver for choosing a low vacuum furnace is economics. They require less complex and expensive pumping systems, achieve their target vacuum level much faster (faster cycle times), and are generally simpler to maintain.

Core Industrial Applications

Low vacuum furnaces are staples in several key manufacturing and heat treatment processes.

Annealing and Stress Relief

Annealing involves heating and cooling a material to increase its ductility and reduce hardness. Using a low vacuum furnace prevents the heavy, flaky scale (oxidation) that would form if the part were heated in open air, resulting in a cleaner finish for components like steel tools.

Brazing

Brazing is a process for joining two pieces of metal using a filler metal. Low vacuum brazing is widely used in the automotive industry, for example, to join aluminum components. The reduced oxygen environment prevents excessive oxidation, ensuring the filler metal can flow properly and create a strong bond.

Sintering

Sintering is the process of compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction. Low vacuum furnaces are used to sinter parts made from powdered metals and certain ceramics where a high-purity environment is not strictly necessary.

Understanding the Trade-offs: Low vs. High Vacuum

Choosing between a low and high vacuum furnace is a critical engineering decision based on a clear set of compromises.

The Purity Ceiling

The most significant limitation of a low vacuum furnace is the residual atmosphere. It cannot be used for processing highly reactive metals like titanium or for applications that demand pristine, contamination-free surfaces, such as medical implants or advanced semiconductor components.

The Speed and Cost Advantage

This is the main benefit. The time it takes to pump down a chamber to a low vacuum level is minutes, whereas achieving a high vacuum can take much longer. This translates directly into higher throughput and lower operational costs per part.

The Inherent Risk of Contamination

The remaining gases in a low vacuum environment—primarily nitrogen, water vapor, and trace oxygen—can still interact with the workpiece. For many applications, this interaction is negligible, but for sensitive materials, it can be detrimental to the final product's quality and performance.

Making the Right Choice for Your Process

Your material and your end goal dictate the correct furnace technology.

- If your primary focus is cost-effective, high-volume heat treatment: A low vacuum furnace is the most efficient choice for non-reactive materials like steel.

- If your primary focus is joining components like aluminum or steel: Low vacuum brazing offers a reliable and economical solution proven in demanding industries.

- If your primary focus is processing highly reactive metals or achieving ultra-high purity: You must use a high vacuum system, as a low vacuum furnace will introduce unacceptable contamination.

Ultimately, selecting the right furnace is about matching the atmospheric requirements of your material to the most economical and efficient technology available.

Summary Table:

| Application | Key Benefits | Ideal Materials |

|---|---|---|

| Annealing | Prevents oxidation, improves ductility | Steel, stainless steel |

| Brazing | Ensures strong bonds, reduces oxidation | Aluminum, steel |

| Sintering | Forms solid parts without high purity needs | Powdered metals, ceramics |

Ready to optimize your heat treatment processes with tailored furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs precisely. Contact us today to discuss how our solutions can enhance your efficiency and reduce costs!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab