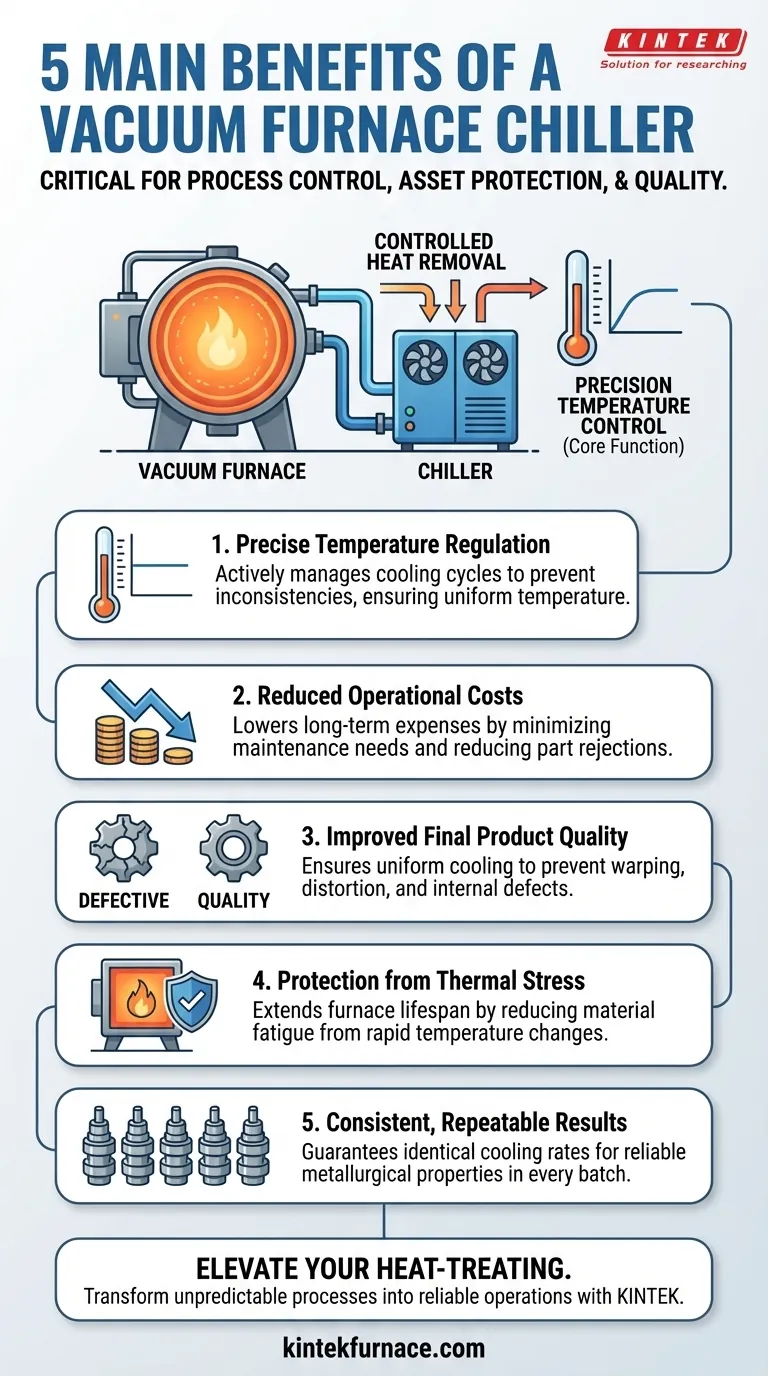

At its core, a vacuum furnace chiller is a critical component for process control and asset protection. The five primary benefits it delivers are precise temperature regulation, reduced operational costs, improved final product quality, protection of the furnace from thermal stress, and the ability to achieve consistent, repeatable heat-treatment results.

A vacuum furnace chiller is not merely a cooling accessory; it is an essential system that provides the control necessary to protect your investment, ensure product consistency, and optimize the efficiency of your entire heat-treating operation.

The Core Function: Precision Temperature Control

A chiller's primary role is to actively remove heat from the vacuum furnace, ensuring temperature is managed precisely during both heating and, most critically, cooling cycles. This control is the foundation for all other benefits.

How a Chiller Enables Control

A chiller circulates a coolant through a closed-loop system connected to the furnace's cooling channels. By precisely managing the temperature and flow rate of this coolant, it removes heat at a controlled, predictable rate, preventing the furnace from getting too hot or cooling down too quickly.

The Problem with Inconsistent Cooling

Without a dedicated chiller, operations might rely on tower water or city water, which can have fluctuating temperatures based on the season or time of day. This lack of control leads to inconsistent cooling rates, which directly compromises the repeatability of your process.

The Direct Impact on Product and Process Quality

The precision offered by a chiller translates directly into higher quality products and more reliable manufacturing processes.

Improving Final Product Quality

Controlled cooling is essential for preventing product defects. Unregulated or uneven cooling can cause warping, distortion, or internal stresses in the material, leading to a higher rate of rejected parts and wasted resources. A chiller ensures uniform cooling, producing dimensionally stable and reliable components.

Achieving Repeatable Heat-Treatment Results

The final metallurgical properties of a part—such as hardness, grain structure, and tensile strength—are determined by the cooling rate (quench). A chiller guarantees that this cooling rate is identical from one batch to the next, ensuring that every part meets the required engineering specifications. This repeatability is impossible to achieve with variable cooling sources.

Understanding the Financial Impact and Trade-offs

While a chiller represents an upfront capital investment, its financial benefits are realized through asset protection and operational efficiency.

Protecting the Furnace from Thermal Stress

A vacuum furnace is a significant capital asset. Rapid, uncontrolled temperature changes cause the furnace's internal components—like the hot zone, chamber walls, and heating elements—to expand and contract. This cyclical stress, known as thermal stress, leads to material fatigue, cracking, and premature failure. A chiller mitigates this by enforcing a gradual, controlled cooling curve.

Reducing Long-Term Operating Costs

Protecting the furnace from thermal stress directly extends its operational lifespan, which can be 10 to 15 years or more with proper care. This defers costly replacements and reduces maintenance expenses over the life of the equipment.

The Hidden Costs of Inconsistency

While a chiller consumes energy, its cost is often offset by the reduction of "hidden" costs. These include the financial losses from scrapped parts, the labor and energy required for rework, and the potential reputational damage from delivering inconsistent products to clients.

How to Justify the Investment

Choosing to integrate a chiller should be based on your specific operational priorities, from quality control to asset management.

- If your primary focus is product quality and repeatability: A chiller is non-negotiable for guaranteeing the consistent cooling rates required for precise metallurgical outcomes.

- If your primary focus is asset protection and longevity: A chiller is the most effective tool for minimizing thermal stress, directly extending the life of your valuable furnace.

- If your primary focus is cost reduction and efficiency: A chiller minimizes waste from rejected parts and reduces long-term maintenance costs, providing a clear return on investment.

Ultimately, a vacuum furnace chiller gives you control over a critical process variable, transforming an unpredictable step into a reliable and optimized operation.

Summary Table:

| Benefit | Description |

|---|---|

| Precise Temperature Regulation | Actively removes heat for controlled cooling cycles, preventing inconsistencies. |

| Reduced Operational Costs | Lowers long-term expenses by minimizing maintenance and part rejections. |

| Improved Final Product Quality | Ensures uniform cooling to prevent defects like warping and distortion. |

| Protection from Thermal Stress | Extends furnace lifespan by reducing material fatigue from temperature changes. |

| Consistent, Repeatable Results | Guarantees identical cooling rates for reliable metallurgical properties in every batch. |

Elevate your heat-treating operations with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum furnace chillers, muffle furnaces, tube furnaces, and more. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and product consistency. Contact us today to discuss how we can optimize your process and protect your investments!

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality