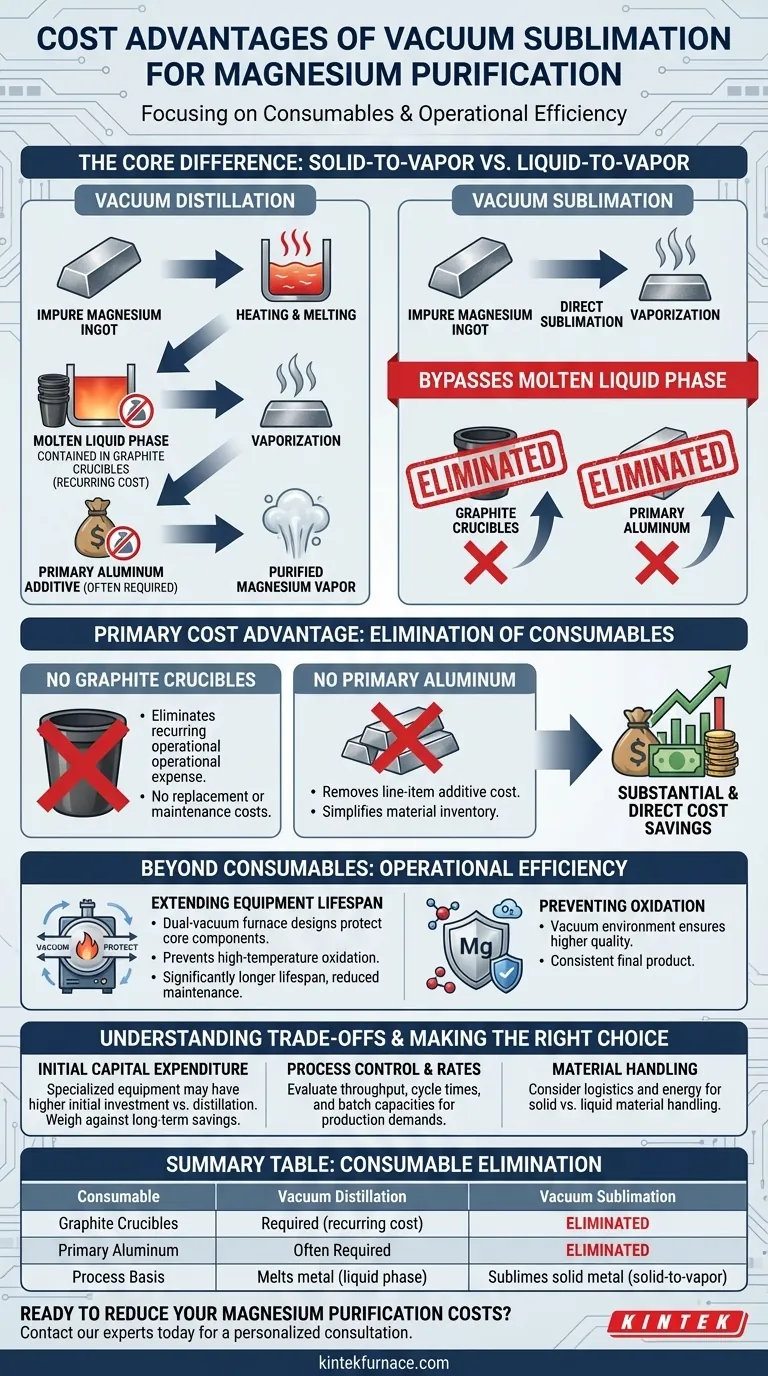

The primary cost advantage is one of elimination. Unlike vacuum distillation, the vacuum sublimation method for magnesium purification completely removes the need for two significant consumables: graphite crucibles and primary aluminum. This is because sublimation converts solid magnesium directly into a vapor, bypassing the molten liquid phase that necessitates these materials.

By avoiding the intermediate step of melting the magnesium, the sublimation process fundamentally redesigns the workflow to make key consumables required by distillation entirely obsolete, leading to substantial and direct cost savings.

The Core Difference: Solid-to-Vapor vs. Liquid-to-Vapor

To understand the cost implications, we must first look at the fundamental mechanics of each purification process. The need for specific consumables is tied directly to the physical state of the magnesium during treatment.

How Vacuum Distillation Works

Vacuum distillation is a two-step process. First, the impure magnesium is heated until it becomes a molten liquid. Then, this liquid is further heated under a vacuum until it vaporizes, leaving impurities behind.

The Role of Graphite Crucibles

Molten magnesium is highly corrosive. The distillation process requires robust graphite crucibles simply to contain this liquid metal during the heating and vaporization stages. These crucibles are a significant and recurring operational expense.

The Need for Primary Aluminum

In many distillation setups, primary aluminum is used as an additive within the molten bath. This consumable is another line-item cost inherent to the distillation method.

How Vacuum Sublimation Works

Vacuum sublimation streamlines the purification process into a single phase change. Solid magnesium ingots are heated directly under a vacuum, causing them to transition from a solid straight to a vapor (sublimation).

Eliminating the Consumables

Because the magnesium never enters a liquid state, the need for a container to hold molten metal is gone. This completely eliminates the cost of purchasing and replacing graphite crucibles. Likewise, the process does not require primary aluminum, removing that expense as well.

Beyond Consumables: A Look at Operational Efficiency

While the savings on consumables are the most direct financial advantage, the design of sublimation systems can also lead to other long-term cost benefits.

Preventing High-Temperature Oxidation

A key benefit of performing this process under a vacuum is the prevention of oxidation. This ensures a higher quality and more consistent final product, regardless of the method used.

Extending Equipment Lifespan

Modern sublimation systems often use a dual-vacuum furnace design. This creates a vacuum not only for the magnesium but also in the space between the inner reaction canister and the outer furnace wall.

This design brilliantly protects the inner canister from being oxidized by ambient air and prevents it from deforming under pressure. The result is a significantly longer lifespan for the core reaction vessel, reducing major replacement and maintenance costs over time.

Understanding the Trade-offs

No technical decision is without trade-offs. While sublimation offers clear advantages in consumables, a complete analysis requires considering the entire operational picture.

Initial Capital Expenditure

The specialized equipment for vacuum sublimation, such as an advanced dual-vacuum furnace, may represent a different initial capital investment compared to traditional distillation setups. This initial cost must be weighed against the long-term savings on consumables.

Process Control and Rates

The rate of purification, or throughput, is a critical factor in overall cost-effectiveness. You must evaluate the cycle times and batch capacities for each method to determine which aligns better with your production demands.

Material Handling

Sublimation begins with solid ingots, while distillation requires melting. The logistics and energy requirements for material handling in each process will differ and should be factored into a total cost analysis.

Making the Right Choice for Your Goal

Your optimal choice depends on which economic factors are most critical to your operation.

- If your primary focus is minimizing recurring operational costs: Vacuum sublimation is the superior choice due to the complete elimination of crucible and aluminum expenses.

- If your primary focus is long-term equipment reliability: The advanced furnace designs associated with sublimation can offer a longer lifespan for core components, reducing maintenance and replacement costs.

- If you are evaluating a new installation: You must weigh the significant long-term consumable savings of sublimation against the initial capital investment and specific throughput requirements of your project.

By understanding these fundamental process differences, you can accurately assess the total cost of ownership for each method.

Summary Table:

| Consumable | Vacuum Distillation | Vacuum Sublimation |

|---|---|---|

| Graphite Crucibles | Required (recurring cost) | Eliminated |

| Primary Aluminum | Often Required | Eliminated |

| Process Basis | Melts metal (liquid phase) | Sublimes solid metal (solid-to-vapor) |

Ready to reduce your magnesium purification costs?

By eliminating the need for expensive graphite crucibles and primary aluminum, the vacuum sublimation method offers a direct path to significant operational savings. Our expertise in high-temperature vacuum furnace systems, including advanced dual-vacuum designs, ensures a reliable and cost-effective purification process tailored to your specific production goals.

Let's discuss how our solutions can enhance your efficiency and profitability. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the significance of porcelain furnaces in academic and scientific research? Unlock Innovation with Precise High-Temperature Control

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab

- Why is a high-precision vacuum tube furnace essential for CVD graphene? Master Growth Control & Purity

- What role do tube furnaces play in semiconductor and battery production? Unlock Precision in High-Temp Processing