The choice of a heating element material in a vacuum furnace is governed by a simple principle: matching the material's properties to the process's demands. The most common materials fall into two primary categories: refractory metals, such as molybdenum and tungsten, which are favored for high-purity processes; and graphite, which is the standard for very high-temperature applications where the presence of carbon is acceptable. Specialized ceramics and metallic alloys serve more niche requirements.

The selection of a heating element is not an isolated choice; it defines the furnace's entire operational capability. Your decision between metallic and non-metallic elements will dictate the achievable temperature, process purity, and long-term operating costs.

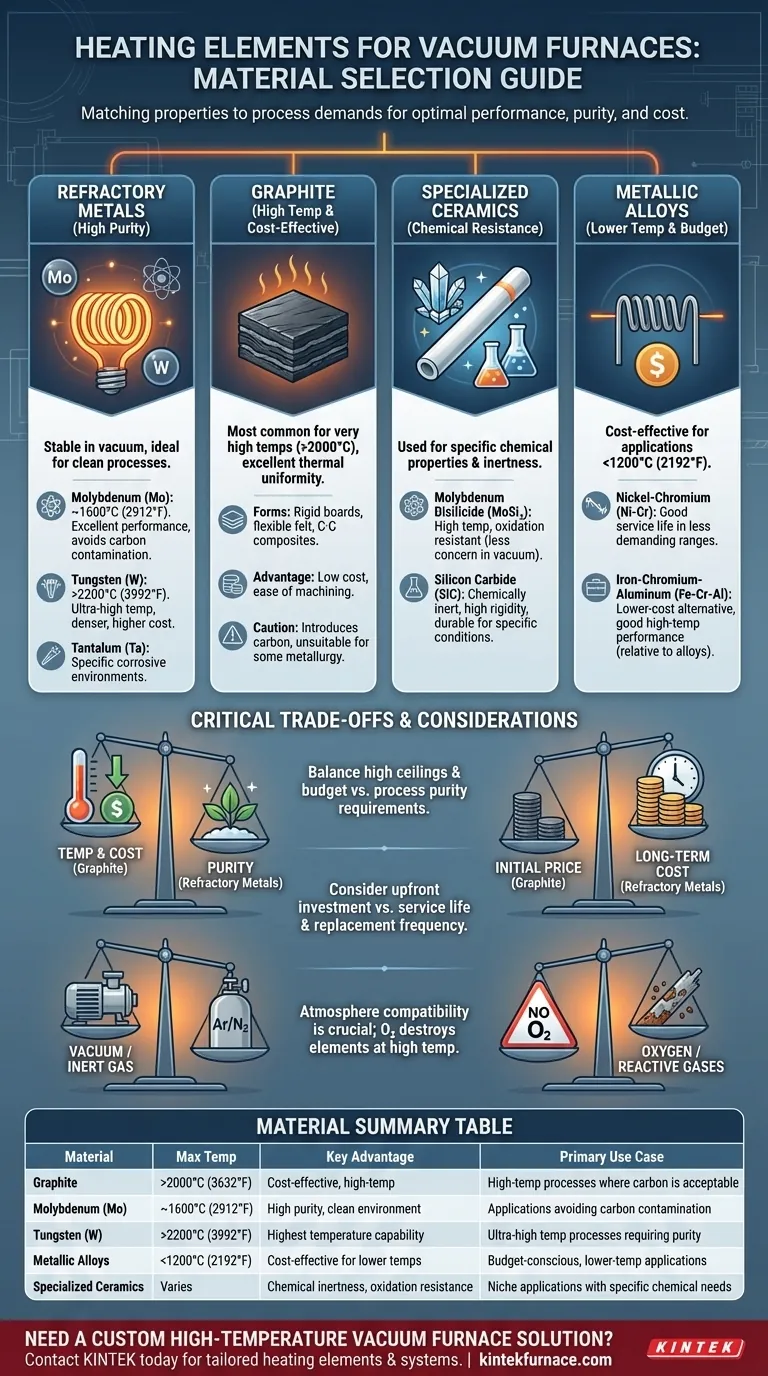

The Primary Material Categories

To understand which element is right for a given task, it's essential to break down the main material groups and their inherent characteristics within a vacuum environment.

Refractory Metals (Molybdenum & Tungsten)

Refractory metals are the workhorse for clean, high-temperature vacuum applications. They are defined by extremely high melting points and stability in a vacuum.

Molybdenum (Mo) is the most common refractory metal element. It provides excellent performance for processes up to approximately 1600°C (2912°F) and is ideal for applications where carbon contamination must be avoided.

Tungsten (W) is used when temperatures must exceed the limits of molybdenum, capable of operating up to 2200°C (3992°F) or even higher. It is denser and typically more expensive than molybdenum.

Tantalum (Ta) is another option, often used in specific corrosive environments, but it is less common than molybdenum or tungsten for general heating applications due to its cost.

Graphite

Graphite is the most prevalent material for very high-temperature vacuum furnaces, often used for applications exceeding 2000°C (3632°F).

Its primary advantages are its low cost, ease of machining, and extremely high-temperature capability. Graphite elements also have excellent thermal uniformity.

These elements are available in various forms, including rigid graphite boards, flexible graphite felt, or durable carbon-carbon composites.

Specialized Ceramics

Ceramic elements are used when specific chemical properties are required, such as extreme resistance to oxidation or interaction with the process materials.

Molybdenum Disilicide (MoSi₂) is a ceramic composite that can operate at high temperatures and offers excellent resistance to oxidation, though this is less of a concern in a proper vacuum.

Silicon Carbide (SiC) is known for its chemical inertness and high rigidity. It is a durable choice for specific atmospheric conditions or when metallic elements are unsuitable.

Metallic Alloys

For lower-temperature vacuum applications, typically below 1200°C (2192°F), traditional resistance alloys are a cost-effective solution.

Nickel-Chromium (Ni-Cr) alloys are ductile and offer good service life in less demanding temperature ranges.

Iron-Chromium-Aluminum (Fe-Cr-Al) alloys present a lower-cost alternative to Ni-Cr with good high-temperature performance, though still well below that of refractory metals or graphite.

Understanding the Critical Trade-offs

Choosing a heating element involves balancing competing priorities. Your decision will have a direct impact on furnace performance, longevity, and operational cost.

Temperature vs. Process Purity

This is the most fundamental trade-off. Graphite offers the highest temperature ceilings at the lowest cost, but it can introduce carbon into the process atmosphere, which is unacceptable for many metallurgical applications.

Refractory metals provide an exceptionally clean heating environment, ensuring high product purity. However, they are more expensive and have practical temperature limits.

Cost of Ownership

The initial purchase price is only part of the equation. Graphite elements can be less expensive upfront but may be more brittle and require more frequent replacement depending on the process cycles.

Refractory metal elements often have a longer service life in a clean, stable vacuum, justifying their higher initial investment. Their efficiency and durability contribute to a lower long-term cost of ownership.

Atmosphere Compatibility

All common heating element materials are designed for use in a vacuum or an inert gas atmosphere. Introducing oxygen or reactive gases at high temperatures will destroy them.

Graphite oxidizes rapidly into gas if a vacuum is lost at temperature. Refractory metals are also highly susceptible to oxidation, which makes them brittle and prone to failure.

Maintenance and Installation

Graphite elements are typically connected using bolted graphite bridges, while metallic elements are welded or mechanically fastened. Both are mounted on high-purity ceramic insulators.

Contamination of these insulators with carbon dust (from graphite) or condensed metal vapors can create electrical shorts. Regular cleaning and careful handling are critical for reliable operation.

Selecting the Right Element for Your Application

Your choice should be guided by your single most important process requirement.

- If your primary focus is maximum temperature and cost-efficiency: Graphite is the default choice, provided the potential for carbon transfer is acceptable for your process.

- If your primary focus is high purity and a clean process environment: Refractory metals like molybdenum (for up to 1600°C) or tungsten (for higher temperatures) are the superior option.

- If your primary focus is a specific chemical environment or corrosion resistance: Specialized ceramics like Molybdenum Disilicide (MoSi₂) should be investigated for their unique properties.

- If your primary focus is lower-temperature applications (below 1200°C) on a budget: Metallic alloys like Fe-Cr-Al provide a practical and reliable solution.

By aligning the heating element's core properties with your specific operational goals, you ensure the long-term reliability and success of your thermal processing.

Summary Table:

| Material | Max Temperature | Key Advantage | Primary Use Case |

|---|---|---|---|

| Graphite | > 2000°C (3632°F) | Cost-effective, high-temperature | High-temp processes where carbon is acceptable |

| Molybdenum (Mo) | ~1600°C (2912°F) | High purity, clean environment | Applications avoiding carbon contamination |

| Tungsten (W) | > 2200°C (3992°F) | Highest temperature capability | Ultra-high temp processes requiring purity |

| Metallic Alloys | < 1200°C (2192°F) | Cost-effective for lower temps | Budget-conscious, lower-temperature applications |

| Specialized Ceramics | Varies | Chemical inertness, oxidation resistance | Niche applications with specific chemical needs |

Need a High-Temperature Vacuum Furnace with the Perfect Heating Element?

Selecting the right heating element is critical to your process success. KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions.

Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability. We can precisely engineer the heating element and furnace system to meet your unique temperature, purity, and budget requirements.

Let us help you achieve optimal performance and reliability. Contact our experts today to discuss your application and receive a tailored solution.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today