At their core, the characteristics of PECVD and LPCVD films are dictated by their deposition method. PECVD (Plasma-Enhanced Chemical Vapor Deposition) uses a low-temperature plasma to achieve high deposition rates, resulting in films with higher hydrogen content and more defects. In contrast, LPCVD (Low-Pressure Chemical Vapor Deposition) relies on high temperatures to produce slower-grown, higher-purity, and higher-quality films.

The decision between PECVD and LPCVD is a fundamental engineering trade-off. You are choosing between the speed and low-temperature flexibility of PECVD and the superior film quality and purity of LPCVD.

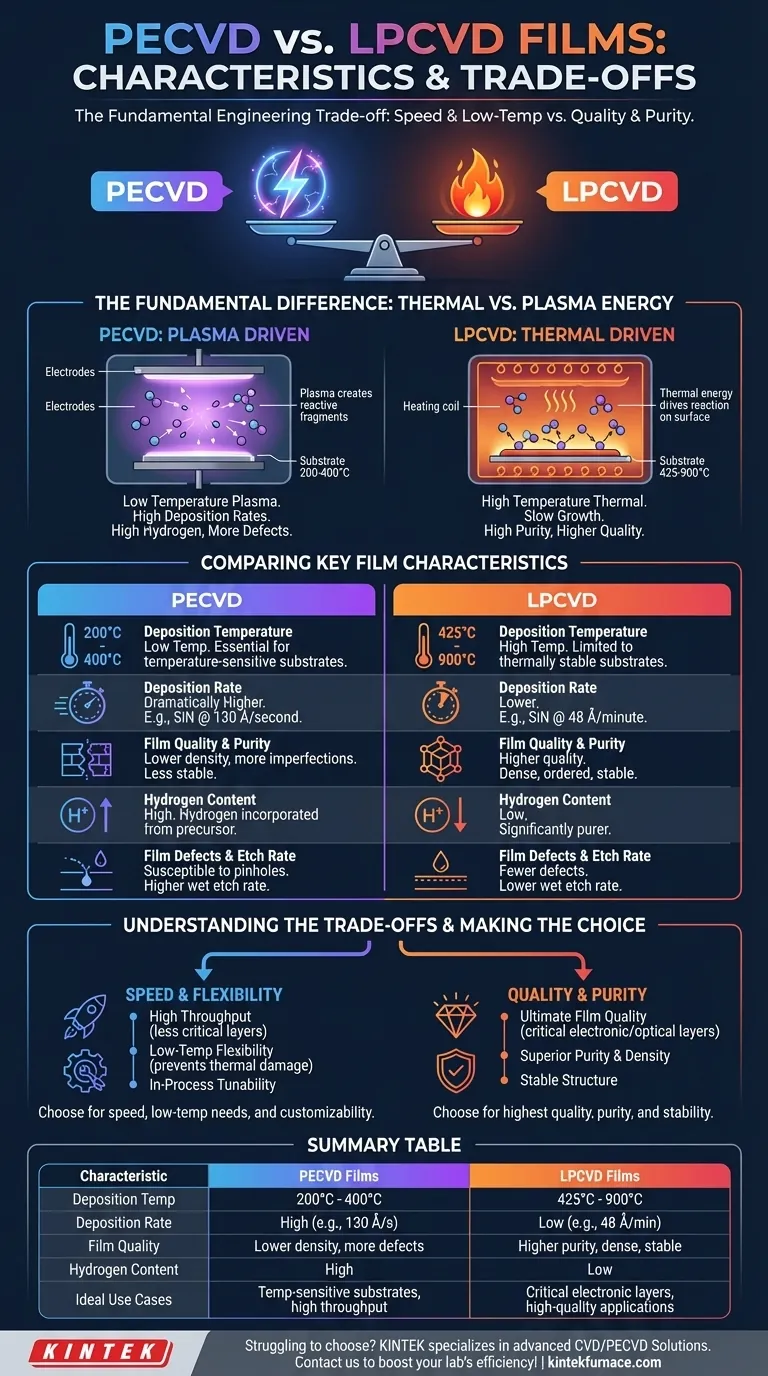

The Fundamental Difference: Thermal vs. Plasma Energy

To understand the difference in film characteristics, you must first understand the energy source each process uses to drive the chemical reaction. This single difference explains nearly every other variation between them.

LPCVD: Driven by Thermal Energy

LPCVD relies exclusively on thermal energy. The substrate is heated to very high temperatures, typically between 425°C and 900°C.

This intense heat gives the precursor gas molecules enough energy to react and form a solid film directly on the hot wafer surface. The process is slow and highly controlled.

PECVD: Driven by Plasma Energy

PECVD uses an electric field to create a plasma, an energized gas. This plasma is highly effective at breaking apart the precursor gas molecules within the chamber, not just on the substrate surface.

These reactive fragments then deposit onto a much cooler substrate, typically between 200°C and 400°C. This allows for deposition without requiring high thermal energy.

Comparing Key Film Characteristics

The difference in energy sources directly impacts the final properties of the deposited film.

Deposition Temperature

This is the most significant differentiator. PECVD's low operating temperature makes it essential for depositing films on temperature-sensitive substrates like polymers or on partially fabricated devices with components that cannot withstand high heat.

LPCVD's high-temperature requirement limits its use to substrates that are thermally stable.

Deposition Rate

PECVD offers a dramatically higher deposition rate. The plasma efficiently creates a high concentration of reactive species, leading to very fast film growth.

For example, PECVD silicon nitride can deposit at rates of 130 Å/second, while LPCVD might deposit the same material at only 48 Å/minute. This gives PECVD a major advantage in throughput.

Film Quality and Purity

This is the primary advantage of LPCVD. The high temperatures and slower growth rates allow atoms to arrange themselves in a more ordered, dense, and stable structure, resulting in a higher-quality film.

PECVD films, formed from a chaotic plasma environment at low temperatures, are less dense and contain more structural imperfections.

Hydrogen Content

PECVD films inherently have a higher hydrogen content. This is because the precursor gases (which often contain hydrogen) are not fully dissociated in the plasma, and hydrogen gets incorporated into the growing film.

This trapped hydrogen can negatively affect the film's electrical properties and long-term stability. LPCVD films are purer, with significantly less hydrogen.

Film Defects and Etch Rate

The lower density of PECVD films makes them more susceptible to defects like pinholes, especially in thinner layers.

They also exhibit a higher wet etch rate compared to LPCVD films. This is a direct indicator of lower film density and quality, as the etchant can penetrate and remove the material more easily.

Understanding the Trade-offs

Choosing a deposition method is not about which is "better" but which is correct for your specific goal. The decision involves balancing competing priorities.

Speed vs. Quality

This is the classic trade-off. If your application requires the highest possible film purity, density, and stability (e.g., for a gate dielectric), the slow, high-quality growth of LPCVD is superior.

If your primary goal is high throughput for a less critical layer (e.g., a passivation layer), the speed of PECVD is a clear winner.

Temperature vs. Device Integrity

Your substrate and existing device structures often make the decision for you. If you must deposit a film without exceeding a certain thermal budget, PECVD is the only viable option.

Exposing a complex, multi-layer integrated circuit to the high temperatures of LPCVD could damage or alter the properties of previously deposited layers.

Process Flexibility

PECVD offers a high degree of in-process tunability. By adjusting parameters like RF frequency, gas flow rates, and electrode geometry, you can actively manipulate film properties such as refractive index, hardness, and stress.

This makes PECVD a more flexible process for developing films with custom-tailored characteristics.

Making the Right Choice for Your Goal

Your application's most critical requirement will guide your decision.

- If your primary focus is ultimate film quality and purity: Choose LPCVD for its dense, low-defect, and low-hydrogen films, which are ideal for critical electronic or optical layers.

- If your primary focus is high throughput and manufacturing speed: Choose PECVD for its exceptionally fast deposition rates, which reduce cycle time and increase wafer output.

- If you are working with temperature-sensitive substrates or materials: PECVD is your necessary choice, as its low-temperature process prevents thermal damage.

- If you must manage the thermal budget of a complex device: Choose PECVD to deposit films late in the fabrication process without altering or damaging underlying components.

By understanding this core trade-off between temperature, speed, and quality, you can confidently select the deposition method that aligns with your specific engineering requirements.

Summary Table:

| Characteristic | PECVD Films | LPCVD Films |

|---|---|---|

| Deposition Temperature | 200°C - 400°C | 425°C - 900°C |

| Deposition Rate | High (e.g., 130 Å/second) | Low (e.g., 48 Å/minute) |

| Film Quality | Lower density, more defects | Higher purity, dense, stable |

| Hydrogen Content | High | Low |

| Ideal Use Cases | Temperature-sensitive substrates, high throughput | Critical electronic layers, high-quality applications |

Struggling to choose between PECVD and LPCVD for your lab? At KINTEK, we specialize in advanced high-temperature furnace solutions, including CVD/PECVD Systems, tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to ensure precise performance for applications like semiconductor fabrication and materials research. Enhance your deposition processes with our reliable equipment—contact us today to discuss how we can boost your lab's efficiency and results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment